Oops!

-----

BTW, the correct answer is among the 3000+ entries in the CB Wiki, and has been for a fairly long time.... We need the proper name, and the use for which it is intended. GO.

.

Last edited:

Oops!

BTW, the correct answer is among the 3000+ entries in the CB Wiki, and has been for a fairly long time.... We need the proper name, and the use for which it is intended. GO.

We have a Winner! you simply place the plate under your flat joint and nail away.Clinch Plate Mabey?

Clinching adds remarkable strength to a joint. A 1948 study by the U.S. Forest Products Laboratory concluded that clinching can increase the holding power of a nail between 45 percent and 464 percent – depending on a variety of factors https://ir.library.oregonstate.edu/dspace/bitstream/1957/2056/1/FPL_1777ocr.pdf

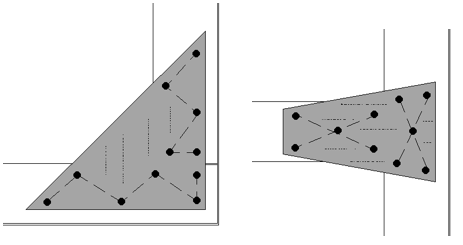

Your looking at someone's "Clinch Plate"... A piece of flat metal used to turn the ends of clinch nails over to lock the plywood scabs on to the 1x3's when building theatrical flats.

I know I'm showing my age here. Back in the day we used clout nails to attach keystones an triangles to flats rather than screws or staples. The nails were about 3/8" longer than required to fasten the 1x and the triangles. You place the steel plate on the floor under the joint. When you pound the nails in with a hammer (yes we used hammers) the end of the nail would curl up when it hit the steel plate. The finished fastener was like a rivet with the head on one side and the curled up end on the other. It made for a strong joint. If you had a concrete floor you don't necessarily need the steel plate but they work better with the steel. I haven't seen clout nails in 40 years.

Let's see:You mean you don't use 13 nails in a corner block and 9 nails in a keystone any more??

We use essential cookies to make this site work, and optional cookies to enhance your experience.