Hey guys-- possible dumb question warning. How to chain hoists work-- Lodestar for example? I know the basics of the rigging/use side but I have no idea how it actually functions. I saw a cutdown one at LDI but without knowing what moves how couldn't quite make sense of it (and kept forgetting to ask them!)

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How do Chain Hoists work?

- Thread starterLavaASU

- Start date

cmckeeman

Active Member

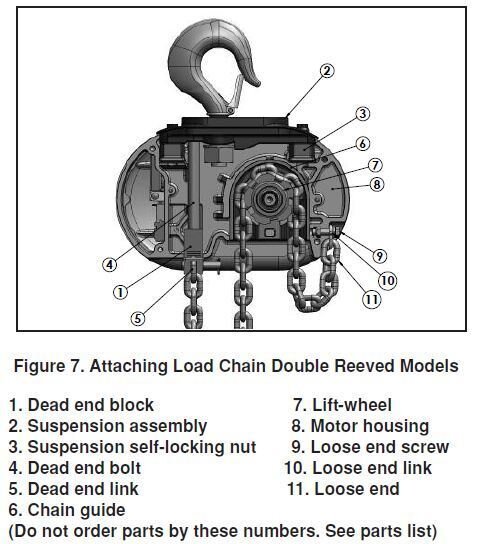

here is a photo of the mechanics, i'm not sure of how the electric parts work but notice that the wheel is hexagonal which means that the speed of the chain will actually vary in a periodic manner also this picture is for a 2 ton where the hook is on a pully instead of at the end of the live chain

Attachments

porkchop

Well-Known Member

Here's my very glazed over and simplified explanation of CM hoists. An electric motor that is small enough to be usable for the application (1/2 - 2 hp in the case of most Loadstars) spins really fast and then there is a very large gear reduction to give the hoist the necessary lifting power and as a trade off makes the chain moves relatively slow (8 - 32 feet per minute is normal, but CM has hoists up to at least 100 feet per minute). There is a very strong brake that holds the shaft that the chain rotates on in place. It is normally engaged and only releases once power is applied. It can be removed manually, but it is a process and because of the gear ratio the chain still doesn't move very fast (with no load applied of course). In every model I've worked on one leg of the input power is transformed down and sent back out to the control device (the amount varies but 24VAC and 48VAC are common control side voltages). Because of this, if a the motor is already supplied power you can use a pickle (Which is kind of a glorified three position momentary switch) to operate it, but more complex controllers that control both the supply of power and movement direction of the hoists are more useful and safer. In the case of a 3 phase hoist the motor will spin in either direction depending on the order of the phases (ABC vs. CBA) because of this it's very important that the hoist controller can only tell the hoist to move in one direction at a time.

Fun facts I've learned about CM hoists:

The speed of most CM hoists is actually dependent on frequency not voltage (there are variety of power configurations available) because of this a hoist that CM sold in the US (60 Hz) as a 16 FPM motor will run at ~13.3 FPM in Europe (50 Hz). The difference matters, trust me.

A model L 1 ton hoist is for all intensive purposes the same unit as a model R 2 ton hoist except the model R has a hook with a pulley allowing it to be a double reeved unit (speed is cut in half, capacity is doubled) and a suspension that's slightly upgraded for the additional capacity. This holds true for many other models of CM hoists.

Lastly a story that we tell in our motor shop but I have not been able to personally confirm. On the load protector in about 8 different languages is says essentially "do not disassemble, contents under extreme pressure." Well at the CM facility one of their shop techs decided since he worked for the manufacturer he didn't have to listen to the warning and he started to disassemble the unit. Soon after he started to split the load protector it released the pressure by means of launching half of the load protector into the ceiling leaving a perfect imprint of the "Do not disassemble" warning. The story says they never repaired the ceiling but left it there to remind other techs to read the warnings.

Fun facts I've learned about CM hoists:

The speed of most CM hoists is actually dependent on frequency not voltage (there are variety of power configurations available) because of this a hoist that CM sold in the US (60 Hz) as a 16 FPM motor will run at ~13.3 FPM in Europe (50 Hz). The difference matters, trust me.

A model L 1 ton hoist is for all intensive purposes the same unit as a model R 2 ton hoist except the model R has a hook with a pulley allowing it to be a double reeved unit (speed is cut in half, capacity is doubled) and a suspension that's slightly upgraded for the additional capacity. This holds true for many other models of CM hoists.

Lastly a story that we tell in our motor shop but I have not been able to personally confirm. On the load protector in about 8 different languages is says essentially "do not disassemble, contents under extreme pressure." Well at the CM facility one of their shop techs decided since he worked for the manufacturer he didn't have to listen to the warning and he started to disassemble the unit. Soon after he started to split the load protector it released the pressure by means of launching half of the load protector into the ceiling leaving a perfect imprint of the "Do not disassemble" warning. The story says they never repaired the ceiling but left it there to remind other techs to read the warnings.

Last edited:

Fun facts I've learned about CM hoists:

The speed of most CM hoists is actually dependent on frequency not voltage (there are variety of power configurations available) because of this a hoist that CM sold in the US as a 16 FPM motor will run at ~13.3 FPM in Europe. The difference matters, trust me.

A model L 1 ton hoist is for all intensive purposes the same unit as a model R 2 ton hoist except the model R has a hook with a pulley allowing it to be a double reeved unit (speed is cut in half, capacity is doubled) and a suspension that's slightly upgraded for the additional capacity. This holds true for many other models of CM hoists.

That is true of all AC motors. In order to speed up or slow down an AC motor you vary the frequency of the power going to it, not the voltage. The higher the frequency, the faster the motor spins. With Europe using a 50 cycle power system everything runs slower then it does in the Americas. If you want to speed it back up, grab a variable frequency drive (VFD) rated for the horsepower of your motor and that should set you up.

What Rigger?

I'm so fly....I Neverland.

Lava, you have gotta keep an eye on this:

CM-ET Training Events

This will keep you up on what classes are upcoming in what areas of the country. Or somewhere in your neck of the woods is probably a dealer who does these classes. The basic class is invaluable in terms of new understanding, and not being afraid of these bad boys in person. (And once you know how to set limits, you become a whole different kind of wizard to a lot of people.) Plus, you get to strip one down to the component level and get that real solid familiarity with "what goes on in there". Plus it's a day spent with other riggers doing what they love, and you'll make friends. The place I go even feeds us, and then CM swags us (BIG time) at the end of the day.

Really, when you get the chance, go and do!

CM-ET Training Events

This will keep you up on what classes are upcoming in what areas of the country. Or somewhere in your neck of the woods is probably a dealer who does these classes. The basic class is invaluable in terms of new understanding, and not being afraid of these bad boys in person. (And once you know how to set limits, you become a whole different kind of wizard to a lot of people.) Plus, you get to strip one down to the component level and get that real solid familiarity with "what goes on in there". Plus it's a day spent with other riggers doing what they love, and you'll make friends. The place I go even feeds us, and then CM swags us (BIG time) at the end of the day.

Really, when you get the chance, go and do!

MPowers

Well-Known Member

.....How to chain hoists work-- Lodestar for example? ......but I have no idea how it actually functions. .....without knowing what moves .......

I don't know, but, I'm not sure anyone has actually answered the question you were asking. I'll try, no guarantees. Using the picture in post #2, the chain (11) is wrapped around the sprocket (7). The sprocket is like the large drive sprocket on a bicycle. The edge is shaped like a negative chain. Instead of sprocket teeth that stick into spaces in the chain, the wheel has recesses that the chain fits into. Just like a bicycle chain, when the wheel turns, the chain feeds on from one side and off the other. In a chain hoist the chain feeding off on the loop side (to the right) piles up or feeds out of, depending on up or down, in a chain bag hanging on the motor. The other end of the chain leads to a load hook (not shown) `and the object being lifted. In the picture as shown, in the conventional or up-right position, The Body hook is fastened to the building steel and the load hook (not shown in the picture) is attached to the truss or whatever is being lifted. When the sprocket wheel turns, the chain is pulled up and over, lifting the load. Inverted use, most common in the entertainment industry, turns the hoist up side down. The free end of the chain with the load hook is fastened to the building steel (using steel slings, spansets, etc.) and the body hook is attached directly to the load. When the hoist is operated, the chain runs over the sprocket wheel and the hoist body is drawn up toward the load hook, bringing the load with it.

Does that help answer the question?

So as I understand it the power is applied to a motor, which spins fast. That is transferred to reduction gears which generate a lot of torque but a lot slower. Those in turn turn the sprocket that hauls the chain.

Theres a brake thats normally engaged but can be released with power. How does that work? I'm assuming some sort of electromagnet?

In the cutaway pic it appears the reduction gears are on the opposite side of the sprocket as the motor. How is that possible? It looks like the shaft coming from the motor goes through the sprocket before reaching the reduction gears.

Does the inverted position have any mechanical affect on the hoists? I would think in one position you'd have issues with the chain wanting to fall out of the pockets...

Sorry for asking a bunch of questions. I'm a very visual person... so I'm basically trying to visulize whats happening inside a hoist when you run it ( can't find a youtube video of that strangely enough!).

Attachments

Last edited:

Haha What Rigger? I'm hoping to take the one-day class if my schedule works out for it. Knowing more about any piece of gear is never bad. And besides I generally feel the more I know about how a *whatever* works the more likely I am to notice/pay attention to a real problem.

porkchop

Well-Known Member

That's a great picture it'll help answer your questions.

Yes exactly it a big, strong electromagnet. If you look at that picture on the top right behind the cabling (the cabling is the limit switch) is the brake.

Magic??? No just kidding. If you look at the cabling on the left (the voltage selection assembly is top left, the transformer is on the right, and reversing contractor is barely visible on the bottom) it prevents the motor from being in the center of the hoist. The output shaft of the motor goes past the lift wheel (same thing as what has previously been called a sprocket) and the reducing gears bring the power back with significantly higher torque. I'm not sure but I would guess this is done to keep the lift wheel as centered in the hoist as possible.

As a side note a certified CM technician can replace these gears to change the lifting power and speed of the motor. For instance a 1 ton 16 FPM model L hoist can become a 1/2 ton 32 FPM model J hoist. If this is done then the hoist needs to be re-load tested at it's new capacity and the modification should be documented in company records.

Some older industrial style hoists used what are called gravity contactors. In these hoists the contactors must be positioned specifically for the orientation that the hoist is to be used in, but they are reversible so you just had to know ahead of time what your orientation would be. On any other kind of contactor system the orientation doesn't matter. The chain guides (I don't think they're pictured but the silver thing below the hook might be them) will keep the chain near the lift wheel when there isn't tension on the chain and any load applied to the chain will keep the chain pulled towards the lift wheel. Also control direction is unaffected by orientation. Up still beings the load hook towards the hoist, and down still sends it away.

These are some great questions, I doubt you'll be the only one that benefits from the answers.

Theres a brake thats normally engaged but can be released with power. How does that work? I'm assuming some sort of electromagnet?

Yes exactly it a big, strong electromagnet. If you look at that picture on the top right behind the cabling (the cabling is the limit switch) is the brake.

In the cutaway pic it appears the reduction gears are on the opposite side of the sprocket as the motor. How is that possible? It looks like the shaft coming from the motor goes through the sprocket before reaching the reduction gears.

Magic??? No just kidding. If you look at the cabling on the left (the voltage selection assembly is top left, the transformer is on the right, and reversing contractor is barely visible on the bottom) it prevents the motor from being in the center of the hoist. The output shaft of the motor goes past the lift wheel (same thing as what has previously been called a sprocket) and the reducing gears bring the power back with significantly higher torque. I'm not sure but I would guess this is done to keep the lift wheel as centered in the hoist as possible.

As a side note a certified CM technician can replace these gears to change the lifting power and speed of the motor. For instance a 1 ton 16 FPM model L hoist can become a 1/2 ton 32 FPM model J hoist. If this is done then the hoist needs to be re-load tested at it's new capacity and the modification should be documented in company records.

Does the inverted position have any mechanical affect on the hoists? I would think in one position you'd have issues with the chain wanting to fall out of the pockets...

Some older industrial style hoists used what are called gravity contactors. In these hoists the contactors must be positioned specifically for the orientation that the hoist is to be used in, but they are reversible so you just had to know ahead of time what your orientation would be. On any other kind of contactor system the orientation doesn't matter. The chain guides (I don't think they're pictured but the silver thing below the hook might be them) will keep the chain near the lift wheel when there isn't tension on the chain and any load applied to the chain will keep the chain pulled towards the lift wheel. Also control direction is unaffected by orientation. Up still beings the load hook towards the hoist, and down still sends it away.

These are some great questions, I doubt you'll be the only one that benefits from the answers.

Last edited:

Brett-- why do I have a feeling you spend a lot of time working with/on motors?

Are there fluids in one of the compartments or something? Or why are there so many separate compartments? I know that they are supposed to be inspected semi regularly and/or if anything strange happens. It looks like they would be a royal pain to take apart to inspect!

The smooth silver wheel between the reduction gears and where the lift wheel should be is the clutch, right?

Are there fluids in one of the compartments or something? Or why are there so many separate compartments? I know that they are supposed to be inspected semi regularly and/or if anything strange happens. It looks like they would be a royal pain to take apart to inspect!

The smooth silver wheel between the reduction gears and where the lift wheel should be is the clutch, right?

porkchop

Well-Known Member

Lets just say I'm intimately familiar with CM hoists...

The only fluid in a hoist is a VERY thick lubricant surrounding the gears (it's most commonly applied with a spoon to give you an idea how thick it is). Other than that the sections are probably there for reinforcement (keep in mind even though the sticker says it's a 1 ton it can be made a 2 ton easily so it has to be very over engineered).

I only know our company policy when it comes to inspections, but for us the center two compartments (liftwheel, chain guides, suspention etc... are one, and the gears are the other) are best left alone unless you have a reason to expect something is wrong (a.k.a. a failed load test or misplaced chain guides). This might have something to with that fact that you are right they are a royal (and messy) pain to take apart and reassemble. As a matter of fact any time you go that far into a motor it has to be re-load tested so we only dive that deep on the road if it's absolutely necessary.

To be perfectly honest I think the silver thing in question is most likely the bearing for the lift wheel. To my knowledge the only clutching that occurs in your standard Lodestar hoist is within the load protector and it only happens in the event of an overload.

The only fluid in a hoist is a VERY thick lubricant surrounding the gears (it's most commonly applied with a spoon to give you an idea how thick it is). Other than that the sections are probably there for reinforcement (keep in mind even though the sticker says it's a 1 ton it can be made a 2 ton easily so it has to be very over engineered).

I only know our company policy when it comes to inspections, but for us the center two compartments (liftwheel, chain guides, suspention etc... are one, and the gears are the other) are best left alone unless you have a reason to expect something is wrong (a.k.a. a failed load test or misplaced chain guides). This might have something to with that fact that you are right they are a royal (and messy) pain to take apart and reassemble. As a matter of fact any time you go that far into a motor it has to be re-load tested so we only dive that deep on the road if it's absolutely necessary.

To be perfectly honest I think the silver thing in question is most likely the bearing for the lift wheel. To my knowledge the only clutching that occurs in your standard Lodestar hoist is within the load protector and it only happens in the event of an overload.

What Rigger?

I'm so fly....I Neverland.

....reeeeeally do not remove. Big spring go BOING!

Personal experience? Or just witnessed/heard about?

Yeah. So update for anyone interested-- I took the basic class. The silver thing I asked about that Brett said is most likely a bearing is in fact (and there's no clutch). And FYI Brett they said that the liftwheel/chainguides/ect need to be inspected at least once a year.

In related news, I imagine this new online CM class would also cover the basics before getting into the maintenance and repair portions for anyone who's interested.

http://www.cmcodepot.com/cm-et-lodestar-online-training.aspx

http://www.cmcodepot.com/cm-et-lodestar-online-training.aspx

Great course, I was one of the first to test it.In related news, I imagine this new online CM class would also cover the basics before getting into the maintenance and repair portions for anyone who's interested.

cm-et-lodestar-online-training

Would you mind if I ask a few questions?Great course, I was one of the first to test it.

How was the (I'm assuming) lack of hands on access handled (video, virtual model, pictures, diagrams, multiple sources)? Is it still able to be a one day course even online (press release mentions one day, but ability to complete on your own time)?

There are copious amounts of interactive diagrams and videos along with quizzes on each section.

The minimum time to complete it is about 4 hours, I took around 6 due to re-watching several sections and taking a lot of notes. (my learning style)

You have up to 90 days to complete the course from the time you register and pay.

The minimum time to complete it is about 4 hours, I took around 6 due to re-watching several sections and taking a lot of notes. (my learning style)

You have up to 90 days to complete the course from the time you register and pay.

Great course, I was one of the first to test it.

Out of curiosity, what do you think you took away from the online course? I took the hands-on course almost two years ago, and as great as the teaching was, I don't think I would have been comfortable stripping a chain hoist if I hadn't had the opportunity to take it apart component by component with the instructor watching. Based on your completion of the course, would you feel comfortable performing maintenance on a chain hoist, then putting it in the air? Are they granting the certification at the completion of the course, or do you still need to do the in-person class to get that? Don't get me wrong, I think it's fantastic that they're now offering the course in a more affordable way, but I'm curious as to how the lack of a physical chain hoist to work with impacts the level of training.

Similar threads

- Replies

- 4

- Views

- 775

- Replies

- 8

- Views

- 3K

- Replies

- 0

- Views

- 679

- Replies

- 6

- Views

- 3K

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)