TechGeek

Active Member

Hey all,

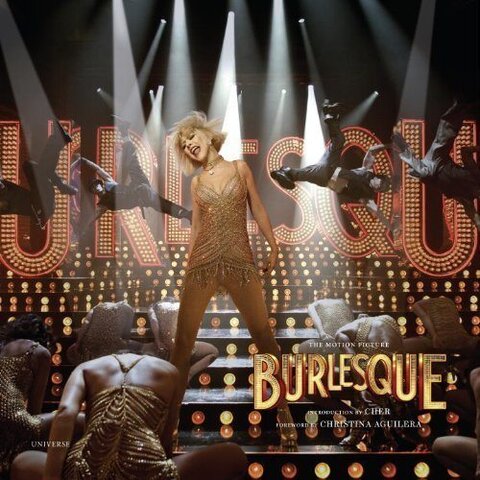

I'm doing work at a theater this summer and we are doing Oh What A Night! it's a tribute to Frankie Valli and the Four Seasons... I was thinking of maybe putting some nice platforms with those built-in marquee lights around the side to add to the show... I don't know if there's a special name for these so if there is please say so!

I've seen these platforms all over and would like to know how the hell they do them in such a way that people aren't shattering bulbs all over the stage and slicing their ankles open.

I also am not sure of what sockets and such to use... wiring is no problem for me, I know basic electrical wiring and have done it. I was thinking of just using these (GE Medium Base Keyless White Porcelain Lampholder-18304 at The Home Depot painted black or these (Leviton Weatherproof Socket - Black-R60-00055-000 at The Home Depot but I don't know how to mount the damn things. Please Help!

or these (Leviton Weatherproof Socket - Black-R60-00055-000 at The Home Depot but I don't know how to mount the damn things. Please Help!

Please excuse all spelling errors.. it's almost 2am here.

I'm doing work at a theater this summer and we are doing Oh What A Night! it's a tribute to Frankie Valli and the Four Seasons... I was thinking of maybe putting some nice platforms with those built-in marquee lights around the side to add to the show... I don't know if there's a special name for these so if there is please say so!

I've seen these platforms all over and would like to know how the hell they do them in such a way that people aren't shattering bulbs all over the stage and slicing their ankles open.

I also am not sure of what sockets and such to use... wiring is no problem for me, I know basic electrical wiring and have done it. I was thinking of just using these (GE Medium Base Keyless White Porcelain Lampholder-18304 at The Home Depot painted black

Please excuse all spelling errors.. it's almost 2am here.