*First off, MEWP seems to be a British acronym (for Mobile Elevated Work Platform) but I'm using it since it's so descriptive.

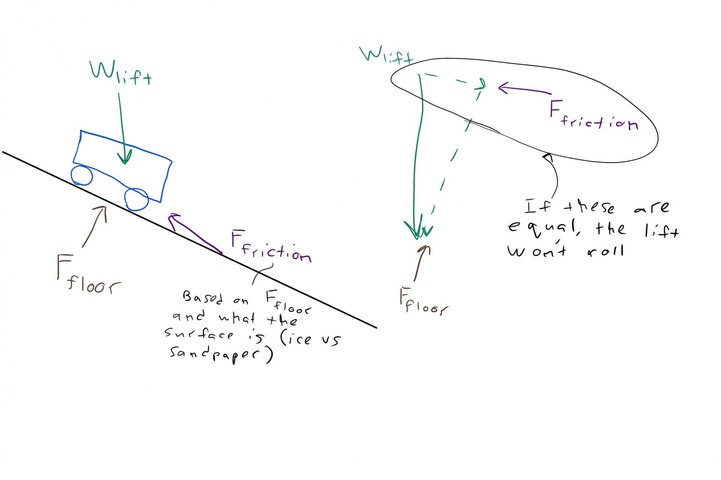

In another thread HERE there is a picture of a scissor lift on a raked floor. I was wondering if there was any standard for using them (and even ladders and scaffold) on a surface that isn't level?

Yes there are ladders that have extendable legs for leveling**. There the threaded bases for scaffold leveling**

** I guess leveling isn't the correct word, I suppose it should be plumb instead.

The Genie AWP and similar do have outriggers with screws for uneven floors, but that doesn't change plumb. There is the Super-Straddle of course which does.

In another thread HERE there is a picture of a scissor lift on a raked floor. I was wondering if there was any standard for using them (and even ladders and scaffold) on a surface that isn't level?

Yes there are ladders that have extendable legs for leveling**. There the threaded bases for scaffold leveling**

** I guess leveling isn't the correct word, I suppose it should be plumb instead.

The Genie AWP and similar do have outriggers with screws for uneven floors, but that doesn't change plumb. There is the Super-Straddle of course which does.