You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Choking spanset on top chord instead of bottom

- Thread starterDagger

- Start date

@Dagger Are you speaking of choking around the upper chord of an overhead structural beam to create a pick point or the top chord of a truss being flown via chain motors or block and falls? I'm assuming the latter but asking for clarity. @What Rigger? @egilson1 Care to comment??

Toodleoo!

Ron Hebbard

Ill let the riggers make the call on this, but from my understanding... no good.

My simple English explanation: Bottom chord suspension puts the load in a compression force, which less likely to cause failure as the truss distributes that load across the diagonals. Top chord causes a tension force, which gets applied directly to all of the weld connections which is bad as they can separate.

My simple English explanation: Bottom chord suspension puts the load in a compression force, which less likely to cause failure as the truss distributes that load across the diagonals. Top chord causes a tension force, which gets applied directly to all of the weld connections which is bad as they can separate.

Ill let the riggers make the call on this, but from my understanding... no good.

My simple English explanation: Bottom chord suspension puts the load in a compression force, which less likely to cause failure as the truss distributes that load across the diagonals. Top chord causes a tension force, which gets applied directly to all of the weld connections which is bad as they can separate.

View attachment 18053

Theres some truth in this, but truss by design is always in tension and compression, depending on what part you look at. Worry about weld quality usually means you should be looking for better welders, not changing your plans.

What will vary are load tables. Most load tables are calculated with truss supported from the bottom, so if you change your approach you may need to talk to the manufacturer about what adjustments you may need.

ok. I'm back.

A quick note: I am going to talk about truss that is manufactured to the ANSI 1.2-2012 standard.

As DanTt mentioned a truss is never just in compression or just in tension. It’s both at the same time. Top chord is in compressions, bottom is in tension. The diagonals alternate between compression and tension as the load “travels” from the force applied to the suspensions. The chords resist the bending moment. The diagonals resist shear.

If we were to try to comply with the “keep the truss in compression” plan, then we should be top hanging all of the loads one the top chord, e.g all of the lights top hung. But we usually hang a majority of the load off the bottom chord. And we also pick from the bottom chord. So we are already deviating from the plan. But in reality the truss is distributing the load through the diagonals, in compression and tension, along the truss chords to the suspensions. It is far more critical to get your suspensions at a node or panel point (where the diagonals intersect) which keeps the chords from being placed in shear.

Years ago I asked the former president of one of the major domestic truss manufacturers about using their truss pick product on the top chord of a truss, as they had it shown in their marketing materials. His response was that as long as you were staying within the loading chart for a given span, you should never be able to “pull” apart the truss. That assumes the welders weren’t drunk (that’s a joke). The manufacturers know we are not going to ALWAYS use the truss by being picking it from the bottom chords and applying the loads to the top chords. The load charts are designed to show you the most force that can be applied to the truss span based on the assumed worse possible hanging configuration.

Now lets take it a step further. Tyler GT truss (https://tylertruss.com/products/gt-plus/) CAN NOT be suspended from the bottom chord. The truss doesn’t have any horizontal spreaders (the parts that hold the two sides of the truss together) between the bottom chords. This is to allow for unobstructed hanging of moving lights. Without them if you pick from the bottom chord you will pull the sides of the truss outwards, which will decrease the strength of the truss. So you have to pick from the top chord, and at panel points.

So what’s the answer to the “should you always pick from the bottom chord” question?

It depends. It’s not a bad practice to do so on standard box truss, but always check with the truss cut sheet/load chart for specific procedures for that truss.

Hope you enjoyed tonight’s bedtime reading.

Regards,

Ethan

A quick note: I am going to talk about truss that is manufactured to the ANSI 1.2-2012 standard.

As DanTt mentioned a truss is never just in compression or just in tension. It’s both at the same time. Top chord is in compressions, bottom is in tension. The diagonals alternate between compression and tension as the load “travels” from the force applied to the suspensions. The chords resist the bending moment. The diagonals resist shear.

If we were to try to comply with the “keep the truss in compression” plan, then we should be top hanging all of the loads one the top chord, e.g all of the lights top hung. But we usually hang a majority of the load off the bottom chord. And we also pick from the bottom chord. So we are already deviating from the plan. But in reality the truss is distributing the load through the diagonals, in compression and tension, along the truss chords to the suspensions. It is far more critical to get your suspensions at a node or panel point (where the diagonals intersect) which keeps the chords from being placed in shear.

Years ago I asked the former president of one of the major domestic truss manufacturers about using their truss pick product on the top chord of a truss, as they had it shown in their marketing materials. His response was that as long as you were staying within the loading chart for a given span, you should never be able to “pull” apart the truss. That assumes the welders weren’t drunk (that’s a joke). The manufacturers know we are not going to ALWAYS use the truss by being picking it from the bottom chords and applying the loads to the top chords. The load charts are designed to show you the most force that can be applied to the truss span based on the assumed worse possible hanging configuration.

Now lets take it a step further. Tyler GT truss (https://tylertruss.com/products/gt-plus/) CAN NOT be suspended from the bottom chord. The truss doesn’t have any horizontal spreaders (the parts that hold the two sides of the truss together) between the bottom chords. This is to allow for unobstructed hanging of moving lights. Without them if you pick from the bottom chord you will pull the sides of the truss outwards, which will decrease the strength of the truss. So you have to pick from the top chord, and at panel points.

So what’s the answer to the “should you always pick from the bottom chord” question?

It depends. It’s not a bad practice to do so on standard box truss, but always check with the truss cut sheet/load chart for specific procedures for that truss.

Hope you enjoyed tonight’s bedtime reading.

Regards,

Ethan

Last edited:

ok. I'm back.

A quick note: I am going to talk about truss that is manufactured to the ANSI 1.2-2012 standard.

As DanTt mentioned a truss is never just in compression or just in tension. It’s both at the same time. Top chord is in compressions, bottom is in tension. The diagonals alternate between compression and tension as the load “travels” from the force applied to the suspensions. The chords resist the bending moment. The diagonals resist shear.

If we were to try to comply with the “keep the truss in compression” plan, then we should be top hanging all of the loads one the top chord, e.g all of the lights top hung. But we usually hang a majority of the load off the bottom chord. And we also pick from the bottom chord. So we are already deviating from the plan. But in reality the truss is distributing the load through the diagonals, in compression and tension, along the truss chords to the suspensions. It is far more critical to get your suspensions at a node or panel point (where the diagonals intersect) which keeps the chords from being placed in shear.

Years ago I asked the former president of one of the major domestic truss manufacturers about using their truss pick product on the top chord of a truss, as they had it shown in their marketing materials. His response was that as long as you were staying within the loading chart for a given span, you should never be able to “pull” apart the truss. That assumes the welders weren’t drunk (that’s a joke). The manufacturers know we are not going to ALWAYS use the truss by being picking it from the bottom chords and applying the loads to the top chords. The load charts are designed to show you the most force that can be applied to the truss span based on the assumed worse possible hanging configuration.

Now lets take it a step further. Tyler GT truss (https://tylertruss.com/products/gt-plus/) CAN NOT be suspended from the bottom chord. The truss doesn’t have any horizontal spreaders (the parts that hold the two sides of the truss together) between the bottom chords. This is to allow for unobstructed hanging of moving lights. Without them if you pick from the bottom chord you will pull the sides of the truss outwards, which will decrease the strength of the truss. So you have to pick from the top chord, and at panel points.

So what’s the answer to the “should you always pick from the bottom chord” question?

It depends. It’s not a bad practice to do so on standard box truss, but always check with the truss cut sheet/load chart for specific procedures for that truss.

Hope you enjoyed tonight’s bedtime reading.

Regards,

Ethan

Is there a difference between choking top cord with spansets all around the truss vs choking top cord ONLY around the top?

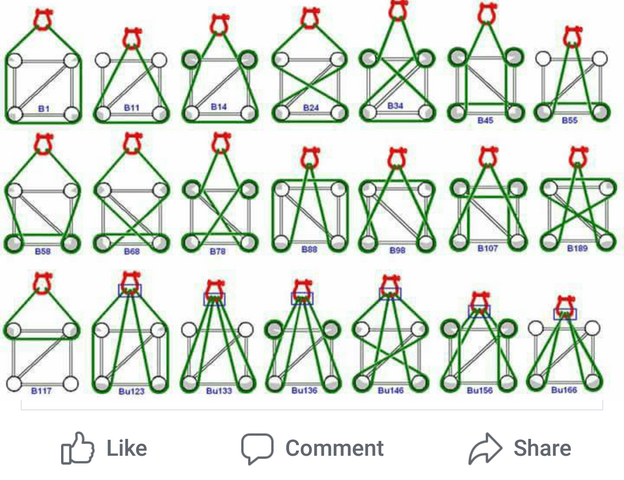

On the image : B1 vs B117

Attachments

Similar threads

- Replies

- 12

- Views

- 1K

- Replies

- 4

- Views

- 1K

- Replies

- 2

- Views

- 1K

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)