MRW Lights

Well-Known Member

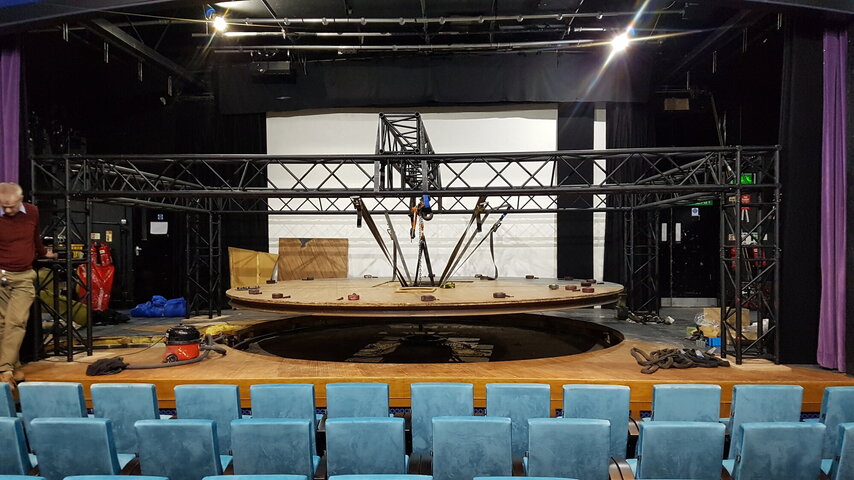

We’re building out a new studio in our broadcast facility and on a wall I have spec’d a 16’ span of aluminum box truss. The architect has kindly offered to save some money by bolting two pieces of 8’ truss together.

So my question was… wouldn’t that effect the weight capacity of the span? He says no it’s the same weight capacity. I said wouldn’t it still need a center support to avoid flexing and he claims a 16’ span split in half would be stronger in the middle.

Additional information- this is a key light truss similar to an FOH position, we’ll never be near the capacity or should cause any amount of flex at the center, but still these are the questions. Also, not being able to hang anything on center is a personal pet peeve, but I can deal with it.

Hoping I can learn more about span length of box truss and effective weight capacity.

So my question was… wouldn’t that effect the weight capacity of the span? He says no it’s the same weight capacity. I said wouldn’t it still need a center support to avoid flexing and he claims a 16’ span split in half would be stronger in the middle.

Additional information- this is a key light truss similar to an FOH position, we’ll never be near the capacity or should cause any amount of flex at the center, but still these are the questions. Also, not being able to hang anything on center is a personal pet peeve, but I can deal with it.

Hoping I can learn more about span length of box truss and effective weight capacity.