I've had a question hanging around in the back of my head for quite a while...

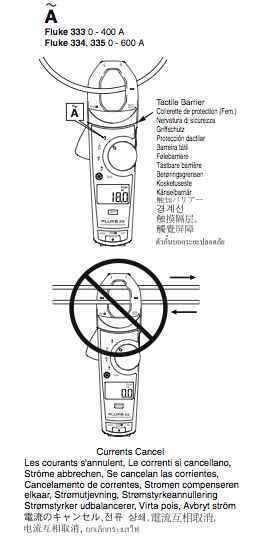

My understanding of a clamp meter, is that you just take a cable, put the cable in between the jaws of the clamp and then it tells you the current going through the cable,and dependent upon how good the clamp meter is, it tells you the voltage etc.

Is that right?

The reason for all this confusion, is that we have a clamp meter at school, and when we clamp it around a cable, it doesn't work... and the rather ambiguous instructions don't say whether they refer to a complete cable, or just one conductor of that, as in a live wire...

It might just be that our clamp meter is dodgy, but I thought I'd make sure, before I get one in the post christmas sales..

Thanks for your help!

My understanding of a clamp meter, is that you just take a cable, put the cable in between the jaws of the clamp and then it tells you the current going through the cable,and dependent upon how good the clamp meter is, it tells you the voltage etc.

Is that right?

The reason for all this confusion, is that we have a clamp meter at school, and when we clamp it around a cable, it doesn't work... and the rather ambiguous instructions don't say whether they refer to a complete cable, or just one conductor of that, as in a live wire...

It might just be that our clamp meter is dodgy, but I thought I'd make sure, before I get one in the post christmas sales..

Thanks for your help!