AshleyB

Member

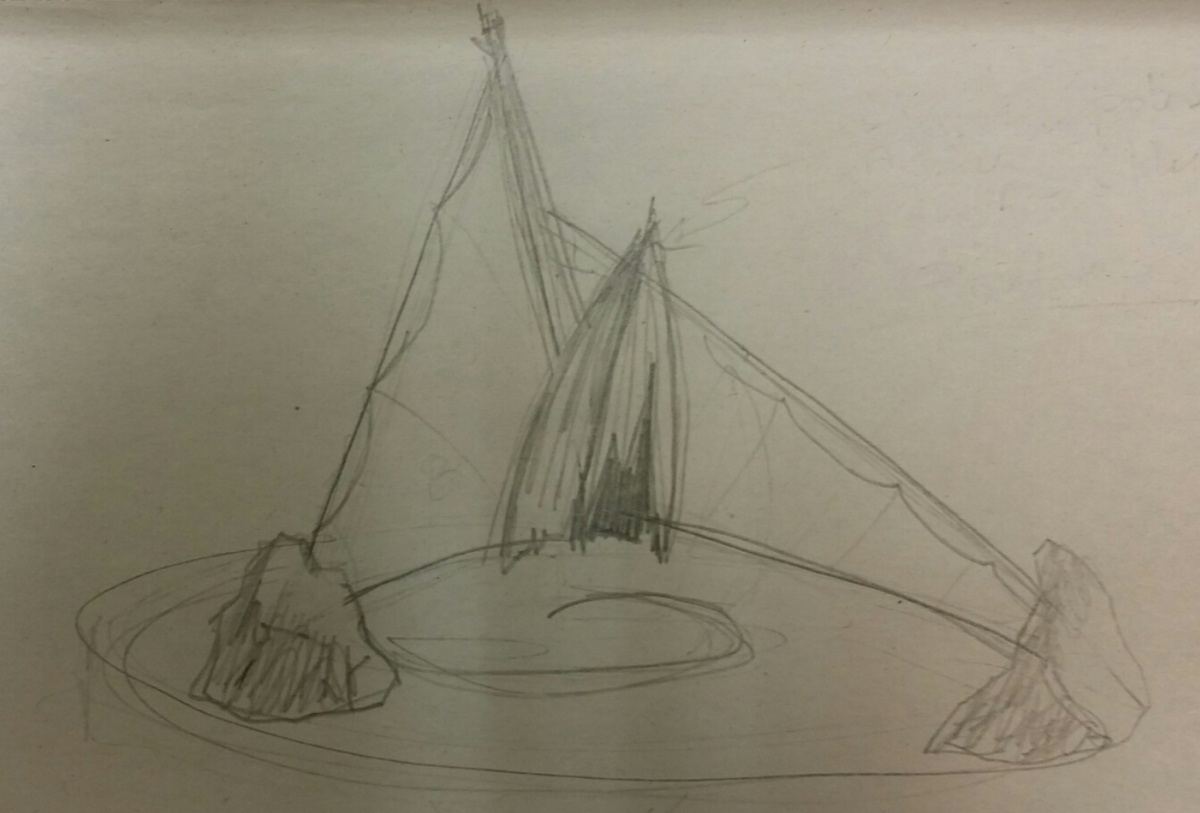

For our upcoming production of the Tempest, I'm looking at incorporating sails from a "shipwreck" as a surface for some silhouette/shadow play. Of course I want my mast tilted (because angles). This will also be the show that we take to competition, so the mast needs to be portable.

I'm submitting this to the Hive Mind for thoughts about:

-construction of the mast itself

-best way to weight/stabilize the mast at the base

I'm attaching an initial sketch (first draft, no scale considerations here)

-The thing in the middle (a busted hull as Prospero's cell) may get cut or moved to reveal more screen real estate)

-The two "sails" may be angled (i.e. not one straight line across the stage) though not curved as it looks in the drawing

-dimensions of the overall sail area are TBD based on what we can safely accomplish, but would like a shadow playing area of 15'h x 20' w - so looking at a pretty tall mast.

High School Theatre, so standard limitations in terms of material availability and experience apply.

Thanks for you time!

I'm submitting this to the Hive Mind for thoughts about:

-construction of the mast itself

-best way to weight/stabilize the mast at the base

I'm attaching an initial sketch (first draft, no scale considerations here)

-The thing in the middle (a busted hull as Prospero's cell) may get cut or moved to reveal more screen real estate)

-The two "sails" may be angled (i.e. not one straight line across the stage) though not curved as it looks in the drawing

-dimensions of the overall sail area are TBD based on what we can safely accomplish, but would like a shadow playing area of 15'h x 20' w - so looking at a pretty tall mast.

High School Theatre, so standard limitations in terms of material availability and experience apply.

Thanks for you time!