kjones9999

Member

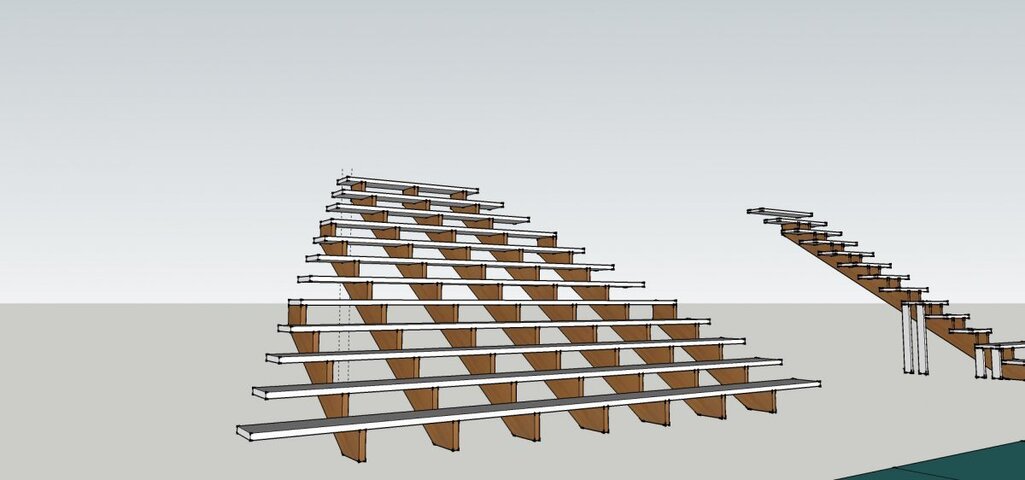

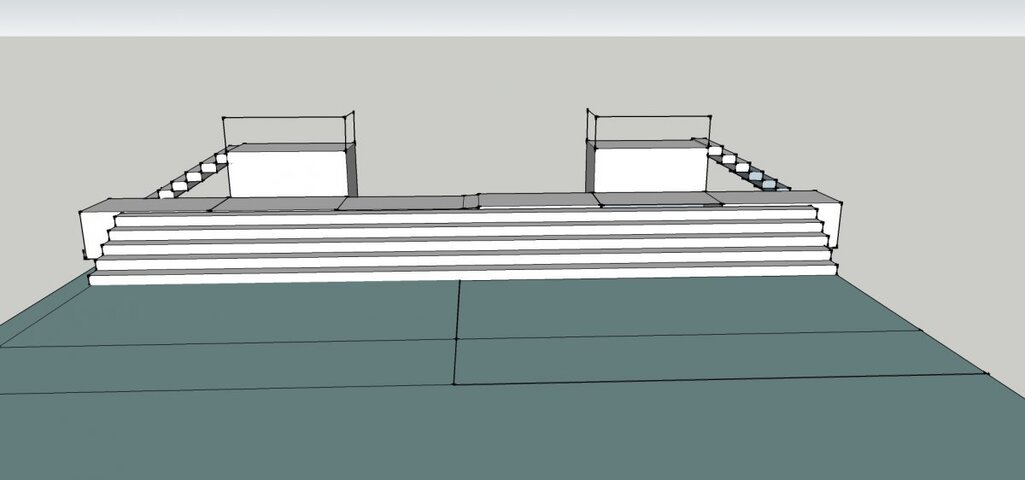

Hi all-- in the process of designing a stair unit--

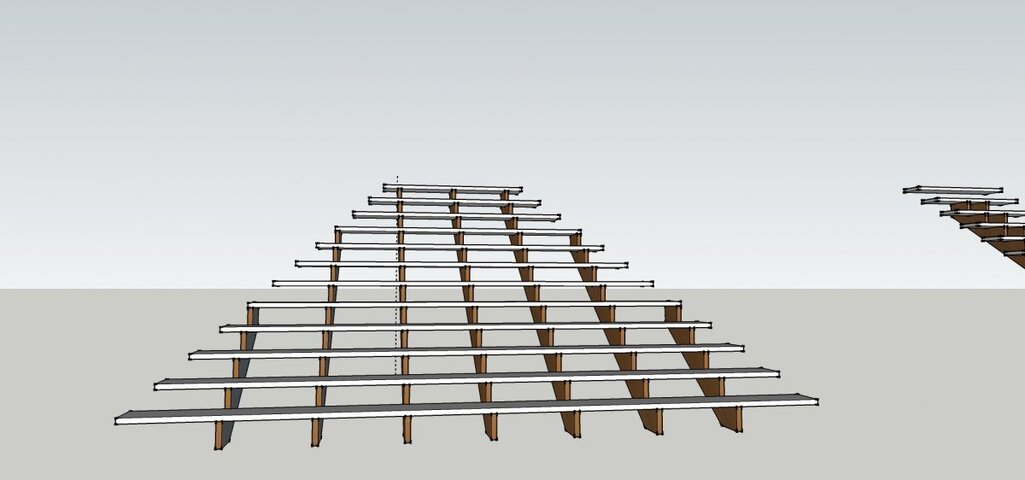

The top tread will be at 88" height and will be 48" wide-

The bottom Tread will 16' wide. Tread depth is approx 1 foot. So basically I need 10 1 foot platforms. Its a big pyramid.

My thinking was to build a series of individually supported 2 foot platforms and have the intermediary step placed on top of that - But is there a better way to support the platforms than individually? If the treads weren't so deep I would consider stringers. But those would seem more trouble than they are worth here.

Any thoughts? These need to be rock solid as they will support 10-12 people at times.

The top tread will be at 88" height and will be 48" wide-

The bottom Tread will 16' wide. Tread depth is approx 1 foot. So basically I need 10 1 foot platforms. Its a big pyramid.

My thinking was to build a series of individually supported 2 foot platforms and have the intermediary step placed on top of that - But is there a better way to support the platforms than individually? If the treads weren't so deep I would consider stringers. But those would seem more trouble than they are worth here.

Any thoughts? These need to be rock solid as they will support 10-12 people at times.