@

This just feels wrong, but it would look great. Is there a safe way to incorporate ladders into a set design instead of stairs? We are building a show that needs to go into multiple spaces and it has a 3 different

platform heights, and ladders would make it all look fantastic and not obscure the cyc-

Thanks!

-rj

@Uncle Dirtnap It would certainly work for me, but then I love ladders and am comfortable on them.

Thoughts:

1; The ladders should extend four to six feet (or more) above the levels they're accessing so performers may safely ascend to the required heights with two hands still on the ladder when stepping sideways on to your platforms as well as for

ease of exiting the platforms.

2; Consider anchoring all four legs of every ladder solidly to the

deck to keep the ladders accurately in position and eliminate any possibilities of the ladders shifting, folding or falling over. This would also make it more difficult for maintenance staff or a visiting trades-person to borrow your ladders during the run of your production.

3; I'm envisioning your ladders positioned SR or SL of your platforms and at 90 degrees such that performers are facing either US or DS while on the ladders then easily stepping sideways when exiting or re-mounting the ladders.

4; A few years ago,

Theatre Aquarius in Hamilton, Ontario, mounted a production calling for two, pristine, 8 or 10

foot ladders in a gleaming natural unfinished wood finish. Aquarius was finding newly constructed wooden step ladders difficult to source until they learned the local Mennonite community in the nearby Kitchener-Waterloo area were still fabricating top quality wooden ladders to order.

4a; The set and LX designers found themselves at odds regarding their ladders with the director and set designers LOVING the clean look of the gleaming, near white, wood while the

lighting designer was finding the ladders the glaring centre of attention especially when needing to light a performer's lengthy monologue being delivered while blocked several steps up a ladder.

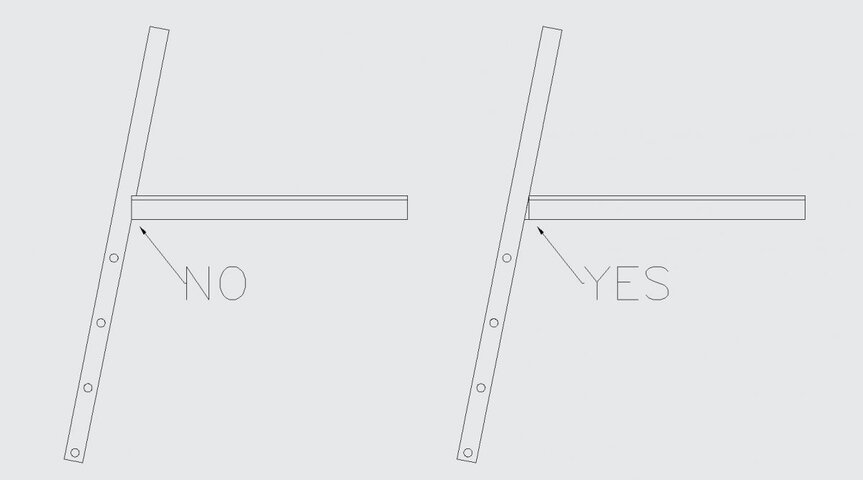

Edit 1: If you aren't fond of the notion of screwing your ladders to your

deck, you might entertain cutting a sheet of 3/4" plywood to the dimensions of your ladder's foot-prints and bolting or screwing a 2" back-flap hinge between each ladder's

leg and where it abuts the 3/4" plywood. The plywood would serve as a rigid spreader and a layer of cast-iron weights from your fly-system would serve to keep the ladder fairly firmly in position. If cast-iron weights aren't readily available in your

venue you may find sand bags, cloth or plastic, suitable.

Edit 2: @Uncle Dirtnap I've re-read your original post and noticed your mentioning "show that needs to go into multiple spaces". With this in mind, I'd suggest 2" back-flap hinges WITH SNUG

FITTING YET EASILY REMOVABLE hinge pins as a solid, yet readily detachable, means of securing your ladders to 3/4" plywood

portable base plates serving as solid, rigid and stable bases which could be quickly and conveniently weighted to keep them in place, stable and secure yet still capable of being quickly struck, folded and packed in a touring application.

Toodleoo!

Ron Hebbard