carsonld

Active Member

Hi all,

My stage is in ROUGH condition. I don’t know the history of it as I’ve inly been here for two out of the 11 years. I think it goes something like:

2009: Theatre opened

2014: stage sanded and repainted by maintenance

20??: stage repainted by drama teacher multiple times

2018: stage repainted by maintenance

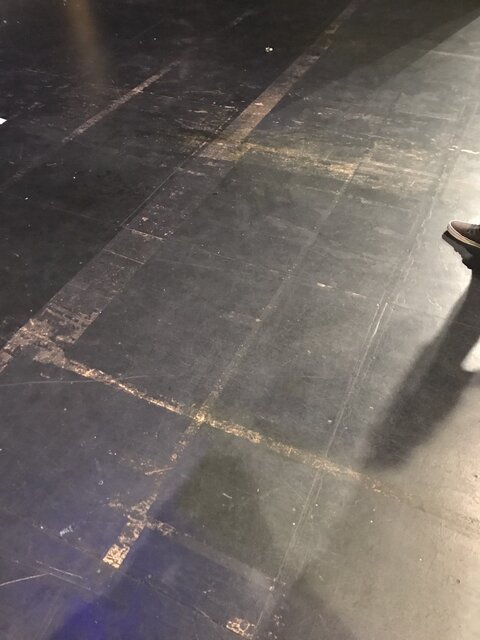

So here’s the thing... the stage is flaking up and tape pulls up the paint. Any type of cable taping? You’re screwed unless you make it 4” wide. When we roll the grand piano across the stage you can literally hear the paint bucking and chipping off. Most of the time is just chips and shows a new layer of paint. However, dance competition season butchered my stage with all the Marley floor. It is now to the point where tape is pulling up all the paint and showing the maso. This past competition event pulled some of the maso particles up.

I’m not sure what to do here. I don’t think I can get the entire stage replaced. If I need to... I’m sure I can bring that discussion up. I would like to see if there are other option before doing that.

I have read BMIs article on painting a stage and have read quite a bit about what I need to do if I had new meso. My question is how screwed is my meso? The painter suggested sanding the entire stage and painting the stage with Rosco tough prime. I like that idea but I’m not sure about sanding the maso. I feel that if you sand too far you’ll ruin the sealer. Can it be resealed?

Another question,

Our orchestra pit is used as the judges location for these dance competitions. Currently the floor is not painted. How can I paint it to protect it from the coffee stains, rolling chairs, etc. that is down there during these competitions? Rosco tough prime? Not sure what material the pit is made of. It needs to be mopped but the floor doesn’t look sealed so I haven’t tried anything. I don’t want to ruin that too!

Thanks in advanced! Keep the stage in your prayers. She needs it

PS: I have attached some pictures so you can see what’s going on. I can take more if it would be helpful! This was last weekend. It’s in a bit tougher shape after the competition this weekend.

My stage is in ROUGH condition. I don’t know the history of it as I’ve inly been here for two out of the 11 years. I think it goes something like:

2009: Theatre opened

2014: stage sanded and repainted by maintenance

20??: stage repainted by drama teacher multiple times

2018: stage repainted by maintenance

So here’s the thing... the stage is flaking up and tape pulls up the paint. Any type of cable taping? You’re screwed unless you make it 4” wide. When we roll the grand piano across the stage you can literally hear the paint bucking and chipping off. Most of the time is just chips and shows a new layer of paint. However, dance competition season butchered my stage with all the Marley floor. It is now to the point where tape is pulling up all the paint and showing the maso. This past competition event pulled some of the maso particles up.

I’m not sure what to do here. I don’t think I can get the entire stage replaced. If I need to... I’m sure I can bring that discussion up. I would like to see if there are other option before doing that.

I have read BMIs article on painting a stage and have read quite a bit about what I need to do if I had new meso. My question is how screwed is my meso? The painter suggested sanding the entire stage and painting the stage with Rosco tough prime. I like that idea but I’m not sure about sanding the maso. I feel that if you sand too far you’ll ruin the sealer. Can it be resealed?

Another question,

Our orchestra pit is used as the judges location for these dance competitions. Currently the floor is not painted. How can I paint it to protect it from the coffee stains, rolling chairs, etc. that is down there during these competitions? Rosco tough prime? Not sure what material the pit is made of. It needs to be mopped but the floor doesn’t look sealed so I haven’t tried anything. I don’t want to ruin that too!

Thanks in advanced! Keep the stage in your prayers. She needs it

PS: I have attached some pictures so you can see what’s going on. I can take more if it would be helpful! This was last weekend. It’s in a bit tougher shape after the competition this weekend.