microstar

Well-Known Member

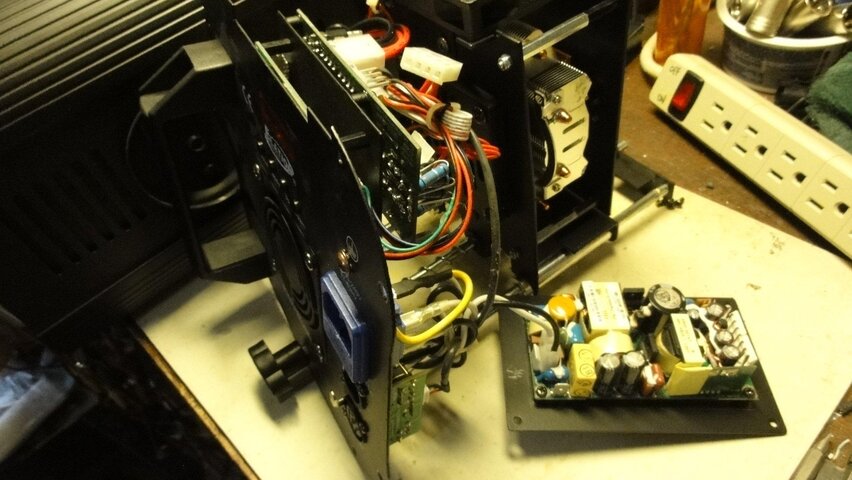

So once again I get to replace failed switching power supplies in LED fixtures (first photo).

Fixture: Elation Opti-Tri PAR LED

10 units out of 12 failed after a power disruption at a local city auditorium last week the night before the final performance.

In 2014 12 units failed in 100 watt Elation ELED Fresnel II fixtures and then in 2017 13 units failed following a power line disruption in a university TV studio (second photo)

The power supply in both fixtures was the ERP (brand name) UHD160-1009 which is a small 2” x 4” 36vdc 4.4A switching unit. Looks like the exact same failure, as described by ERP in their “failure analysis report” after I decided to send a couple of units in after the 13 failed.

Hopefully Elation is not using this particular power supply any more, but I wouldn’t bet on it. Interesting to note that when I went to order replacements for the Opti-Tri PARs from LightParts, they sent a 24vdc 6.66A unit after having verified with Elation that it was a proper replacement. Unfortunately, haven’t been able to locate someplace that would do component-level repairs on the failed units (for a reasonable cost that is).

Interestingly, both installs also had Altman LED fixtures (Chalice houselights at the auditorium and SpectraCycs at the TV studio) which were unfazed.

I wonder how often we have these kinds of failures to look forward to as LED fixtures become the norm?

Fixture: Elation Opti-Tri PAR LED

10 units out of 12 failed after a power disruption at a local city auditorium last week the night before the final performance.

In 2014 12 units failed in 100 watt Elation ELED Fresnel II fixtures and then in 2017 13 units failed following a power line disruption in a university TV studio (second photo)

The power supply in both fixtures was the ERP (brand name) UHD160-1009 which is a small 2” x 4” 36vdc 4.4A switching unit. Looks like the exact same failure, as described by ERP in their “failure analysis report” after I decided to send a couple of units in after the 13 failed.

Hopefully Elation is not using this particular power supply any more, but I wouldn’t bet on it. Interesting to note that when I went to order replacements for the Opti-Tri PARs from LightParts, they sent a 24vdc 6.66A unit after having verified with Elation that it was a proper replacement. Unfortunately, haven’t been able to locate someplace that would do component-level repairs on the failed units (for a reasonable cost that is).

Interestingly, both installs also had Altman LED fixtures (Chalice houselights at the auditorium and SpectraCycs at the TV studio) which were unfazed.

I wonder how often we have these kinds of failures to look forward to as LED fixtures become the norm?