You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's the worst install you've.....

- Thread starterBillESC

- Start date

High school asked for a bid for a total renovation/new install. The initial meeting was pretty productive with a lot of input, the second meeting not so much. The band director decided that they wanted to be a road house for tours and decided they needed top line equipment. Spec’d they a full Meyer rig per their request (wanted exactly what was in most riders...) and after he saw the cost, he said he’d have to rethink the decision.

About a year and a half later, I got an emergency call from this school asking to PLEASE come for a repair. Bose amp wasn’t “running surround sound from the board”. Auto feedback system doesn’t work. Sounds hollow, what’s wrong?

The architect “knew a good sound man” who installed a Bose system which would have been underpowered in a living room. Mains were hung on the side walls 4’ above stage level surrounding the auditorium, subs were above the stage 24’ high. Every XLR wall jack was male. Contractor said female jacks break too easily, so sold them enough f-to-f adapters to use. Wiring to every XLR jack was two wire, no ground (hence no phantom power). Band director didn’t own condenser mics anyhow. Subs had never been used because the janitor blew them when the system was first installed and the contractor replaced the mains but didn’t touch the subs. Feedback unit wasn’t hooked up, plus no one ever told them what an eq was for. Wireless mics were sold without mics, just body packs, and rack was under the sound desk in the rear of the auditorium‘s sound/lighting booth.

Asked the band director what the budget was and how extensive of a renovation they wanted. He turned white. They’d just opened the fully remodeled school and couldn’t afford any more renovations. I advised them to get their solicitor to go after the GC, sold them a 1000w JBL system for assemblies (against my wishes but they saw an ad in one of the DJ catalogs...) and gave them my boss’s number for rentals. They’re faithful renters now, but it’s a shame they didn’t do it right in the first place.

About a year and a half later, I got an emergency call from this school asking to PLEASE come for a repair. Bose amp wasn’t “running surround sound from the board”. Auto feedback system doesn’t work. Sounds hollow, what’s wrong?

The architect “knew a good sound man” who installed a Bose system which would have been underpowered in a living room. Mains were hung on the side walls 4’ above stage level surrounding the auditorium, subs were above the stage 24’ high. Every XLR wall jack was male. Contractor said female jacks break too easily, so sold them enough f-to-f adapters to use. Wiring to every XLR jack was two wire, no ground (hence no phantom power). Band director didn’t own condenser mics anyhow. Subs had never been used because the janitor blew them when the system was first installed and the contractor replaced the mains but didn’t touch the subs. Feedback unit wasn’t hooked up, plus no one ever told them what an eq was for. Wireless mics were sold without mics, just body packs, and rack was under the sound desk in the rear of the auditorium‘s sound/lighting booth.

Asked the band director what the budget was and how extensive of a renovation they wanted. He turned white. They’d just opened the fully remodeled school and couldn’t afford any more renovations. I advised them to get their solicitor to go after the GC, sold them a 1000w JBL system for assemblies (against my wishes but they saw an ad in one of the DJ catalogs...) and gave them my boss’s number for rentals. They’re faithful renters now, but it’s a shame they didn’t do it right in the first place.

I’m assuming the ground is isolated to prevent any noise...

soundlight

Well-Known Member

This is the saddest detail I've ever had to incorporate into bid documents. The original installer had their logo plate in every equipment rack, of which there were 3 installed racks and 8 portable lectern racks. I can't remember if I decided to blur their logo out but I remember thinking long and hard about whether or not I should.

DavidJones

Well-Known Member

Several times, by different companies unqualified to create build specs and contractors who have never seen a DMX cable or a Camlock, I've had to remedy camlocks on disconnects that were all gendered MALE, all 5-pin DMX gendered backward, and plenty of cat 5 cables with A termination one side and B on the other. I'm not even sure how many venues I have seen that put ALL of their company switches on stage left, and no power on stage right(They never want to fix this, they would rather just hire hundreds of feet of cable per show.

A $90 million new building, 3 performance spaces, many, many recording locations, a huge lobby, etc..... multiple A/V closets with Ethernet patchbays connecting every other patchbay.

Either the consultant neglected to specify it, or the install contractor just didn’t do it, but none of the patchbays have labels for the wiring. We’ve no idea where anything goes or comes from.

The contractor wants to get paid, 2 years now, the college is pushing us to get “trained” on the system, we keep refusing when A) We are certain there’s gear missing and B) The system is mostly unusable unless it’s labeled.

Either the consultant neglected to specify it, or the install contractor just didn’t do it, but none of the patchbays have labels for the wiring. We’ve no idea where anything goes or comes from.

The contractor wants to get paid, 2 years now, the college is pushing us to get “trained” on the system, we keep refusing when A) We are certain there’s gear missing and B) The system is mostly unusable unless it’s labeled.

@SteveB A 'Fox & Hound', or cheap 'n cheerful equivalent, with adapters to RJ45 (or whatever) will rapidly become your new best buddy.A $90 million new building, 3 performance spaces, many, many recording locations, a huge lobby, etc..... multiple A/V closets with Ethernet patchbays connecting every other patchbay.

Either the consultant neglected to specify it, or the install contractor just didn’t do it, but none of the patchbays have labels for the wiring. We’ve no idea where anything goes or comes from.

The contractor wants to get paid, 2 years now, the college is pushing us to get “trained” on the system, we keep refusing when A) We are certain there’s gear missing and B) The system is mostly unusable unless it’s labeled.

Toodleoo!

Ron Hebbard

There are just a lot of hacks out there because there is no formal training for this kind of work. Most installers only know what they were taught. It's no better in broadcasting. Despite my protestations, a contractor was hired to build our new studios and did a complete hack job. It'll take me at least a year to resolve the worst of the problems, and I will have to live with their mess until I retire or quit. The only good thing I can say is its on the air most of the time.

Ancient Engineer

Well-Known Member

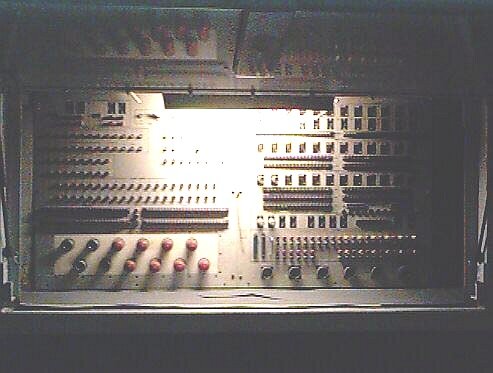

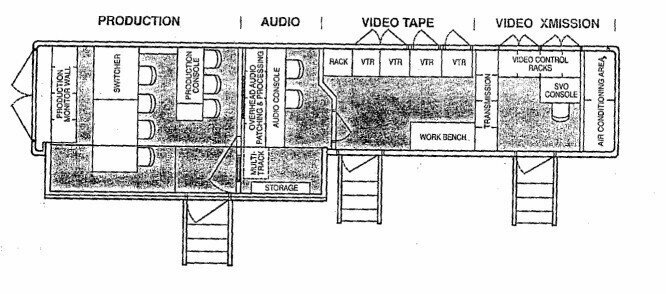

My personal worst ever: In the early 2000s I was chief engineer at a company that built television remote trucks. We got in a steel 48' single expando trailer that was a full nine camera setup. All analog. Old analog. Like, late 1970s Grass valley 300 series video switcher (the original death star control panel BTW), and the like. I think the most advanced VTR on the poor thing was a Sony 2500 1" machine for slo-mo...

Anyhow the task was to strip the analog video out of the backbone and have a hybrid digi/log system with HDSDI as outputs.

We got into the thing and ended up taking the entire guts out as a do-over. Why? Rust. Lots and lots of rust.

Turns out that when Gerstenslager (that is actually the name of the company) built the thing as a bookmobile in 1972 it had an expected lifespan of ten years. So it was welded up and painted on the outside only... Fast forward thirty years and it was an orange flaky mess on the inside.

Four months later and about sixty gallons of POR15, re-assembly begins. But, some schmarty in the warehouse had been taking pieces of the interior home to install in his camper... So we ended up basically starting from zero.

Fast forward a year and it is on the road making good pictures and sound (It had a rare "broadcast" MCI JH600 console in it!).

The usual turnaround on something like this was about 90 days, we were two days over a full year... The customer was ultimately satisfied.

I was just tired of going home looking like a 6'3" tall Oompa-loompa after all the rust removal...

These are the "before" pictures... I will have to find the "after" pictures...

Anyhow the task was to strip the analog video out of the backbone and have a hybrid digi/log system with HDSDI as outputs.

We got into the thing and ended up taking the entire guts out as a do-over. Why? Rust. Lots and lots of rust.

Turns out that when Gerstenslager (that is actually the name of the company) built the thing as a bookmobile in 1972 it had an expected lifespan of ten years. So it was welded up and painted on the outside only... Fast forward thirty years and it was an orange flaky mess on the inside.

Four months later and about sixty gallons of POR15, re-assembly begins. But, some schmarty in the warehouse had been taking pieces of the interior home to install in his camper... So we ended up basically starting from zero.

Fast forward a year and it is on the road making good pictures and sound (It had a rare "broadcast" MCI JH600 console in it!).

The usual turnaround on something like this was about 90 days, we were two days over a full year... The customer was ultimately satisfied.

I was just tired of going home looking like a 6'3" tall Oompa-loompa after all the rust removal...

These are the "before" pictures... I will have to find the "after" pictures...

Last edited:

You don’t want to get me started on the quality of work I see from even large AV integrators with good national reputations.

Apparently, soldering is no longer a necessary skill to teach an AV technician. I always pull plates during punch walks and find deficiencies in at least 3 out of 4.

Apparently, soldering is no longer a necessary skill to teach an AV technician. I always pull plates during punch walks and find deficiencies in at least 3 out of 4.

Last edited:

You don't want to see the remnants of a Neutrik XLR 7 contact cable female after an IBEW brother's spent two hours atop a scissor lift brutalizing it with an iron better suited to soldering eaves troughs. Poor sad little lump of mis-shapened plastic with a few discernible flakes of metal drowning within it.You don’t want to get me started on the quality of work I see from even large AV integrators with good national reputations.

Apparently, soldering is no longer a necessary skill to teach an AV technician. I always pull plates during lunch walks and find deficiencies in at least 3 out of 4.

Toodleoo!

Ron Hebbard

Ancient Engineer

Well-Known Member

Yes... the not-so-minor difference between a soldering "gun" and an "iron".

I worked with a guy that had an 80W "iron"... you coulda sweated copper pipe with it. He managed to make good Switchcraft XLRs with it though.

I worked with a guy that had an 80W "iron"... you coulda sweated copper pipe with it. He managed to make good Switchcraft XLRs with it though.

Similar threads

- Replies

- 10

- Views

- 969

- Replies

- 13

- Views

- 2K

- Replies

- 5

- Views

- 730

- Replies

- 2

- Views

- 758

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)