Jay Ashworth

Well-Known Member

This was tried for residential wiring in the 70s, and didn't really take off, for a number of reasons...

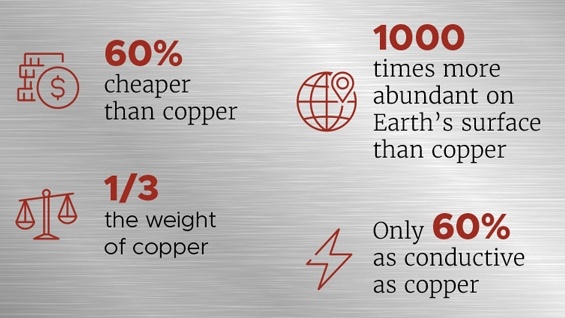

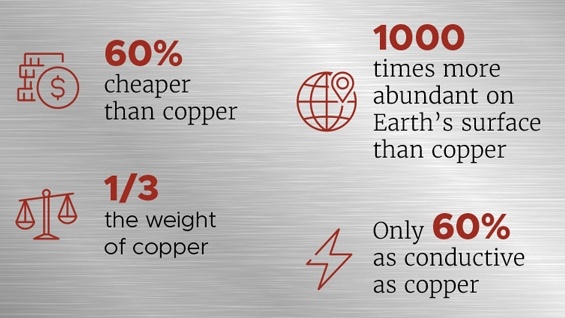

but materials scientists assert that they've figured out ways to modify the fundamental properties of metals like aluminum to allow it to have electrical conductivity 80-90% that of copper, instead of the current 60%.

I wouldn't put off your black-box rewire right now, but...

www.techbriefs.com

www.techbriefs.com

but materials scientists assert that they've figured out ways to modify the fundamental properties of metals like aluminum to allow it to have electrical conductivity 80-90% that of copper, instead of the current 60%.

I wouldn't put off your black-box rewire right now, but...

Highly Conductive Aluminum Can Equal Copper

(Image: Shannon Colson | Pacific Northwest National Laboratory) A first-ever simulation of aluminum conductivity offers a recipe for an inexpensive substitute for copper.