AyCee

Member

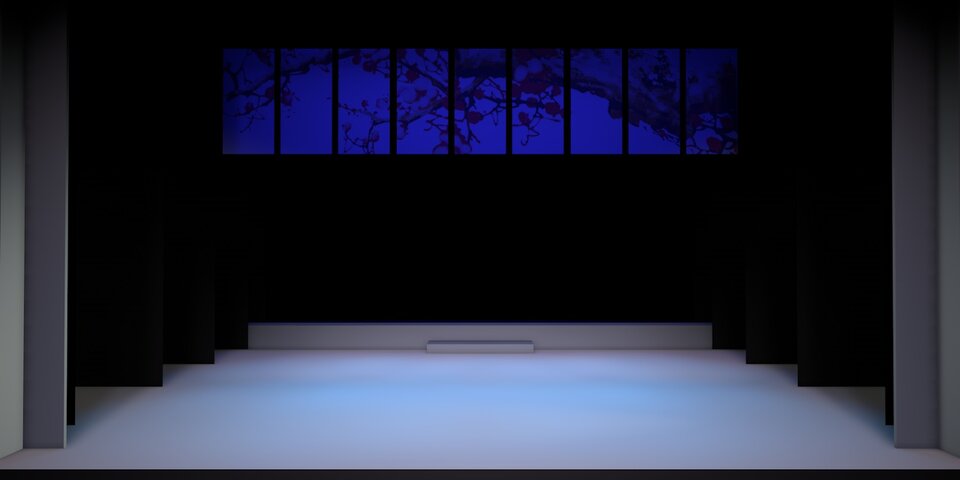

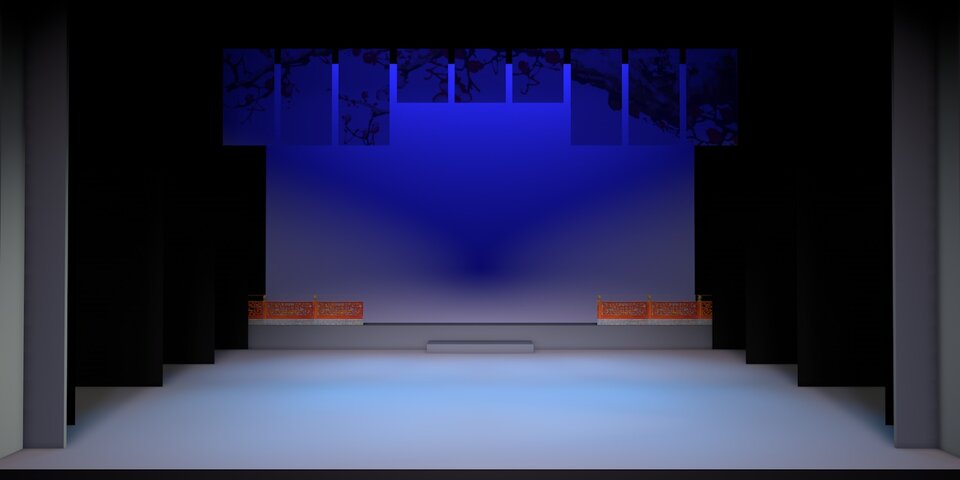

Hi everyone, I have a set which comprise of 9 fabric panels which ideally should be aligned in a line horizontally, and grouped into 3 groups, so that these fabric panels can have different levels for different scenes.

My initial idea was to have the panels of each group tied to one batten, and these battens are then rigged to the same flybar, and raised or dropped to required height via ropes and pulleys, but my regular set contractor told me this method is hard to achieve, and suggested me to use 3 flybars instead, but I am not exactly keen, because that would mean my frontmost panel and the backmost panel will be 1/2 a metre apart (each flybar is spaced at 25cm apart from each other), and to me that is quite ugly. Moreover, I have a row of raised platform that needs to be flushed as close to the back of the panels as possible, so this method is not within my consideration. What other alternatives do you guys have?

I have 2 other ideas, which I am not sure which is better, or how feasible they are:

1. Using 2 adjacent flybars, with one of them brailed to as close to the other one as possible, the center stage group will rig directly to one of these flybars and flown it and out the "regular" way, while the other 2 groups will be rigged to the other flybar and manually raised and dropped via rope and pulley.

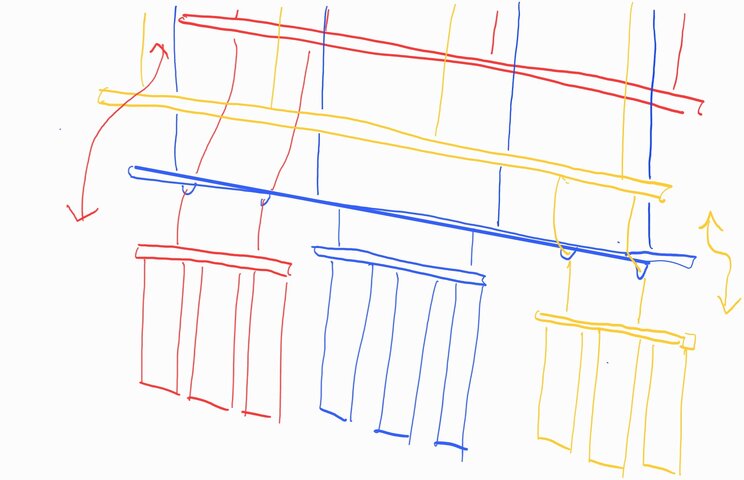

2. Using 3 adjacent flybars, the center stage group will be rigged directly to the middle flybar, whereas the other 2 groups will be rigged to the flybars in front and behind respectively, but the rigging rope will pass through eyelets rigged onto the middle flybar, so when the front and back flybars fly in or out, the battens of these 2 groups will still be flying up and down in the same horizontal position as the center stage group. (I have attached a very rough sketch of the mechanism here as well).

Any thoughts about these 2 ideas?

My initial idea was to have the panels of each group tied to one batten, and these battens are then rigged to the same flybar, and raised or dropped to required height via ropes and pulleys, but my regular set contractor told me this method is hard to achieve, and suggested me to use 3 flybars instead, but I am not exactly keen, because that would mean my frontmost panel and the backmost panel will be 1/2 a metre apart (each flybar is spaced at 25cm apart from each other), and to me that is quite ugly. Moreover, I have a row of raised platform that needs to be flushed as close to the back of the panels as possible, so this method is not within my consideration. What other alternatives do you guys have?

I have 2 other ideas, which I am not sure which is better, or how feasible they are:

1. Using 2 adjacent flybars, with one of them brailed to as close to the other one as possible, the center stage group will rig directly to one of these flybars and flown it and out the "regular" way, while the other 2 groups will be rigged to the other flybar and manually raised and dropped via rope and pulley.

2. Using 3 adjacent flybars, the center stage group will be rigged directly to the middle flybar, whereas the other 2 groups will be rigged to the flybars in front and behind respectively, but the rigging rope will pass through eyelets rigged onto the middle flybar, so when the front and back flybars fly in or out, the battens of these 2 groups will still be flying up and down in the same horizontal position as the center stage group. (I have attached a very rough sketch of the mechanism here as well).

Any thoughts about these 2 ideas?