Sigh.

This really isn't relevant, but I want to share it. (Mods, if this is in the wrong section, feel free to move it).

The local High School is doing a performance of some sort, and I was asked to come in and help with the lighting...

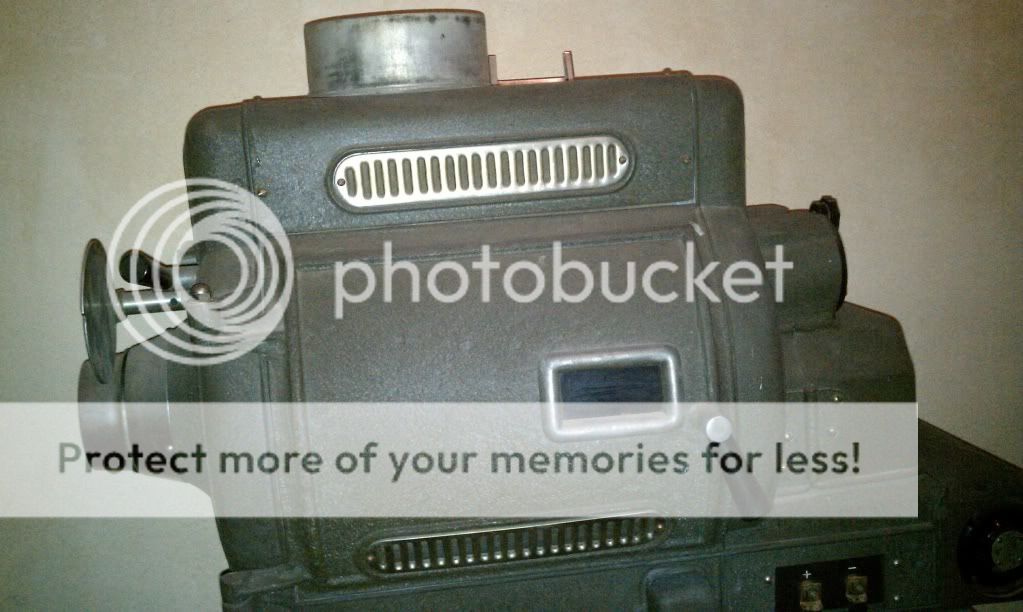

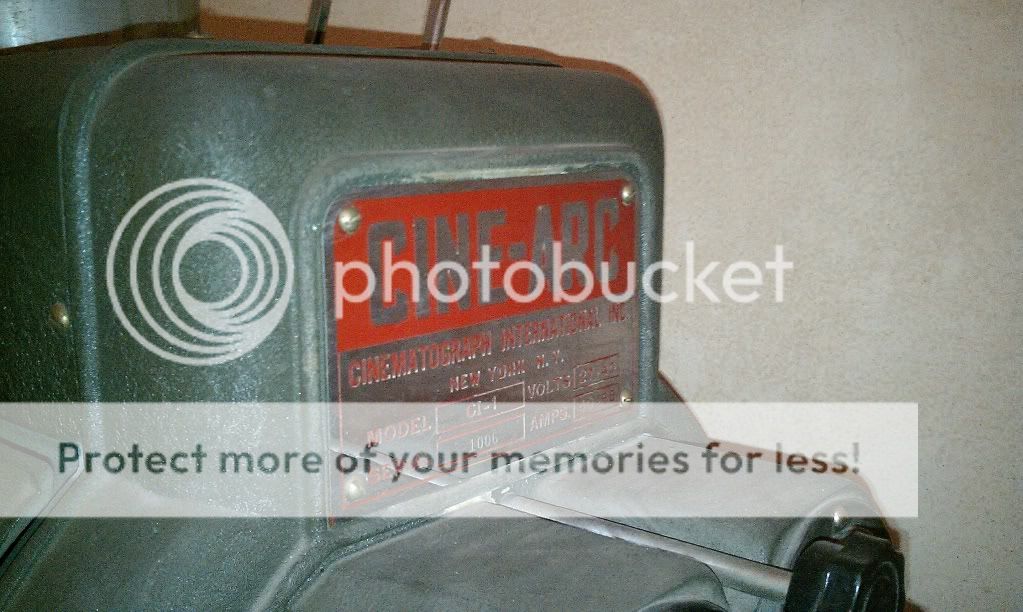

Well, guess what I find when I get there? A old, old spotlight that was purchased in 1948. No joke-it produces so much Carbon Monoxide, that you don't want to be within 50 feet of it for more than ten seconds (unless the fan is on. Then there is less Carbon Monoxide...which is safer?)

No joke-

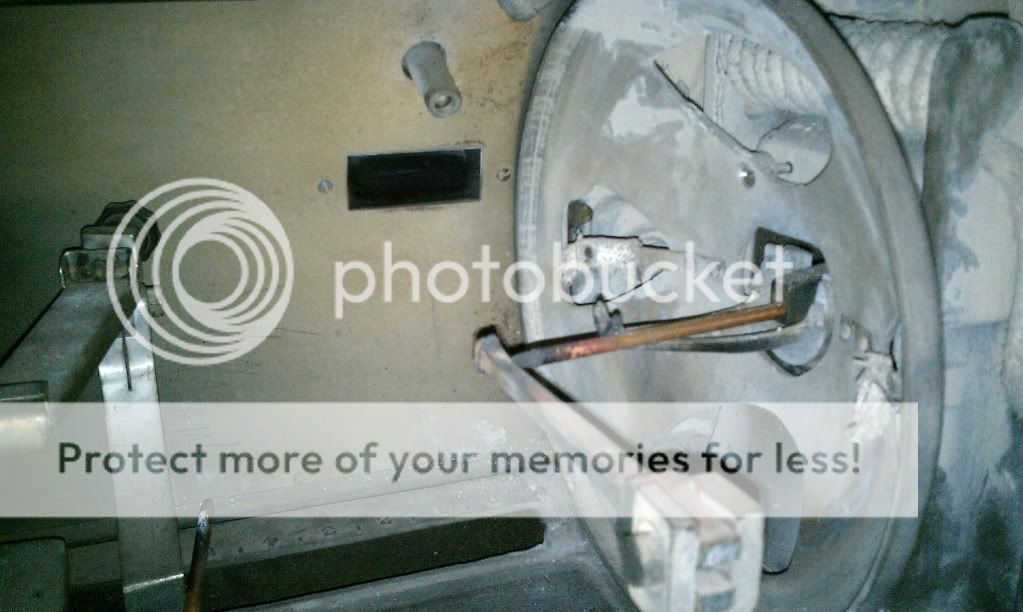

I had to change the carbon rods (which burn for approx one hour and 15 minutes) which was...interesting.

Then you have to create an electrical current between them by pulling them apart and pushing them closer. As the show goes and the spot is on, you have to constantly wind them to keep you light on and visible.

I didn't even know these things exsited anymore...

This really isn't relevant, but I want to share it. (Mods, if this is in the wrong section, feel free to move it).

The local High School is doing a performance of some sort, and I was asked to come in and help with the lighting...

Well, guess what I find when I get there? A old, old spotlight that was purchased in 1948. No joke-it produces so much Carbon Monoxide, that you don't want to be within 50 feet of it for more than ten seconds (unless the fan is on. Then there is less Carbon Monoxide...which is safer?)

No joke-

I had to change the carbon rods (which burn for approx one hour and 15 minutes) which was...interesting.

Then you have to create an electrical current between them by pulling them apart and pushing them closer. As the show goes and the spot is on, you have to constantly wind them to keep you light on and visible.

I didn't even know these things exsited anymore...