Allana

Active Member

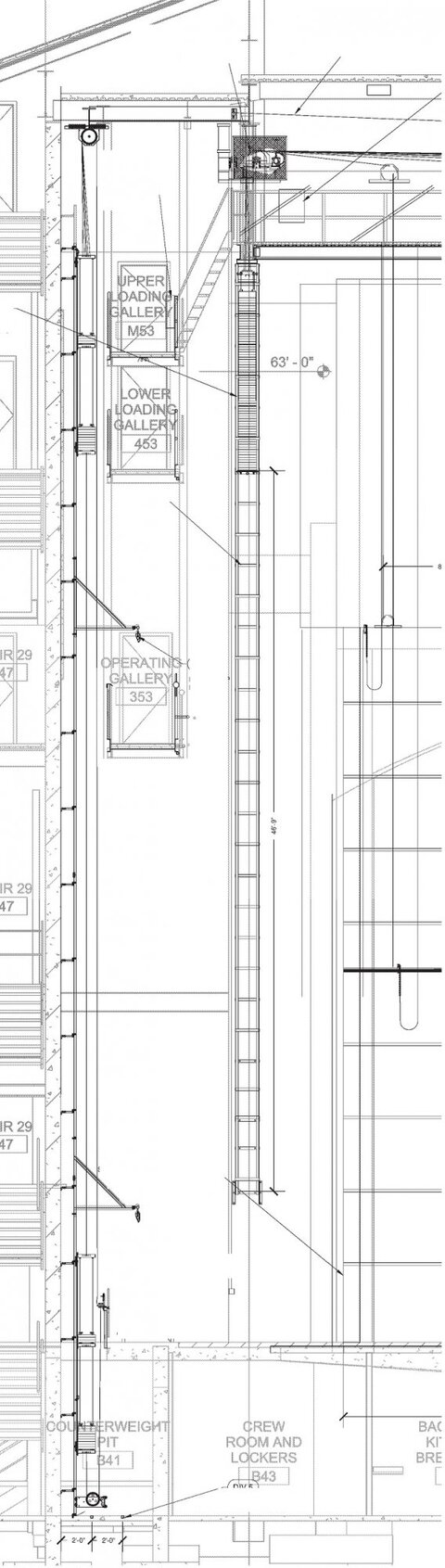

My theater has both an upper and lower loading gallery. On install, the JR Clancy rep told us to distribute 2/3 of the weights on the upper loading gallery and 1/3 on the lower. From a physics perspective, does this weight distribution actually effect whether the system is "in weight"?

This 2/3rds process is physically harder on 1 loader than the other and takes more time. I'm wondering if the project can be split 50/50, knowing that something Very heavy would require more weight up top since the lower would run out of room.

Secondly, how likely is it for someone on the lower loading gallery to be hit from a falling brick from the upper? Should they actually be loading one-at-a-time? That would slow this process down to an excruciating crawl.

This 2/3rds process is physically harder on 1 loader than the other and takes more time. I'm wondering if the project can be split 50/50, knowing that something Very heavy would require more weight up top since the lower would run out of room.

Secondly, how likely is it for someone on the lower loading gallery to be hit from a falling brick from the upper? Should they actually be loading one-at-a-time? That would slow this process down to an excruciating crawl.