Hello,

As you may have noticed I'm new here, was browseing inet and some how ended up here. Seen some topics simular to mine, so figure can't hurt to ask. In my attempt to retire from auto repair, all that has transpired is that now I am still repairing auto's but from my home(20+ years you build a loyal customer base that refuse to let anyone else repair theyre cars...lol). So to make things a lil easyer on my back and knees, I purchased a 2Post 9K autolift. Now the lift needs 220V Single phase 25A max(@45 second duration). I have a normal 110V breakerbox/meterwhere the drop comes off the pole. And some how(was already here when bought house) I have 1-4prong plug in the garage that runs my 220V Mig welder just fine. But to splice off this plug is not a option(concrete driveways/trees ect prevent this). But to splice off the box is possable. So what I am needing to know, is it possable to some how use the 110V to get my single phase 220V to operate my lift. Had a electrician give a est of around 4K+(was talking bout he had to install a new box ect-seamed like he was giving me something and it didn't include a kiss). Now if there is a 220V plug already on the far side of garage it seams like it should be possable but not sure how to do it and keep single phase with voltage doubled. With the cost already for the lift and the concrete slab $$$ is tight so trying to save any penny I can after all I am RETIRED...lol So any suggestions

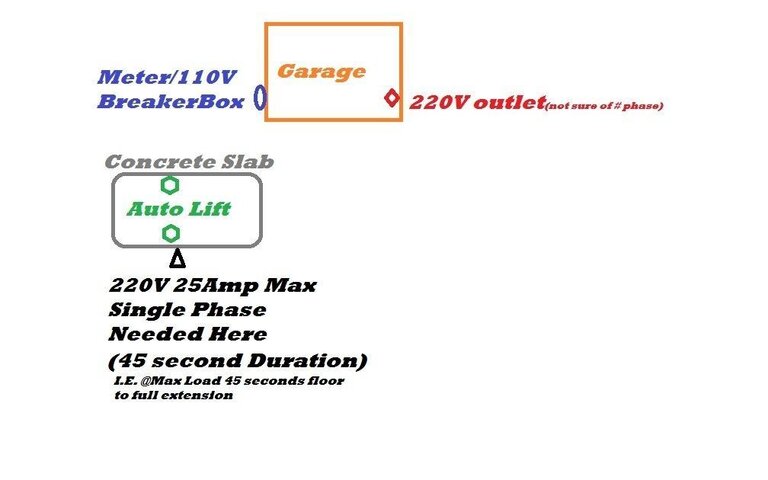

suggestions here would be great. Here is a image(sorta) of my layout. OH, the lift has only 2 wire leads for imput voltage along with 1 ground(3 leads total).

here would be great. Here is a image(sorta) of my layout. OH, the lift has only 2 wire leads for imput voltage along with 1 ground(3 leads total).

As you may have noticed I'm new here, was browseing inet and some how ended up here. Seen some topics simular to mine, so figure can't hurt to ask. In my attempt to retire from auto repair, all that has transpired is that now I am still repairing auto's but from my home(20+ years you build a loyal customer base that refuse to let anyone else repair theyre cars...lol). So to make things a lil easyer on my back and knees, I purchased a 2Post 9K autolift. Now the lift needs 220V Single phase 25A max(@45 second duration). I have a normal 110V breakerbox/meterwhere the drop comes off the pole. And some how(was already here when bought house) I have 1-4prong plug in the garage that runs my 220V Mig welder just fine. But to splice off this plug is not a option(concrete driveways/trees ect prevent this). But to splice off the box is possable. So what I am needing to know, is it possable to some how use the 110V to get my single phase 220V to operate my lift. Had a electrician give a est of around 4K+(was talking bout he had to install a new box ect-seamed like he was giving me something and it didn't include a kiss). Now if there is a 220V plug already on the far side of garage it seams like it should be possable but not sure how to do it and keep single phase with voltage doubled. With the cost already for the lift and the concrete slab $$$ is tight so trying to save any penny I can after all I am RETIRED...lol So any