You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

4'x16' platform - 10' high

- Thread startermalibu

- Start date

JChenault

Well-Known Member

Hey guys, 1st post.

On the set design I was just givin for our fall show. The SD wants a 4x16 platform 10' high. Would it work to just do normal double 2x4 legs with a lot of bracing, or is there a better way?

Thanks!

You will likely have two issues with this. One is the entire platform wiggling when someone walks on it. This can be addressed by lots of cross bracing, (within the 4 x 16 space of the platform). The second issue you should think about is the stability of the entire unit. If I have a perfectly solid platform that is 4 feet wide at the narrowest, and 10 feet tall, it is will be tippy and the whole thing could fall over.

To fix this second problem you need some kind of bracing to make the base wider - in the 4 foot direction. Stairs ( I assume there are some stairs in this - otherwise how could anyone get up there) might provide the diagonal bracing outside of the footprint of the platform. Tieing the unit to a wall or other solid architectural feature will help, as will attaching the feet to the floor. Note that just attaching the feet will probably not be enough for safety. At the very least you will need to tie the feet into the floor, and then run some diagonal bracing from the top of the platform to the floor so that the effective base is closer to 8 or 10 feet wide.

I think JChenault, covered most of the important parameters. With the proper amount of cross bracing and perhaps a couple of jacks on the US side you should be fine. Depending on the load you could almost get away with 1x4 "hog-trough" for legs. 10' feet is right on the edge of safe "Legging within the foot print" of a platform.

I agree with Van, hog-trough legs are a good option. I've seen people get really hardcore and do them out of 2x6.

Whats nice a platform like this is that if you have two stock 4x8 platforms it's partly built already.

Apparently we're going to be building a rather large and tall platform for Midsummer, so I'll be sure to post some info on that process.

Whatever you decide secure crossbracing is a must.

Whats nice a platform like this is that if you have two stock 4x8 platforms it's partly built already.

Apparently we're going to be building a rather large and tall platform for Midsummer, so I'll be sure to post some info on that process.

Whatever you decide secure crossbracing is a must.

I use a stud wall system. See this article for a detailed description with pictures of building both the platforms and the leg units. No reason you couldn't build them 10' high using the same technique. For platforms 8' or higher and narrow (like yours) I would add some jacks to guarantee it won't tip.

JChenault

Well-Known Member

I think JChenault, covered most of the important parameters. With the proper amount of cross bracing and perhaps a couple of jacks on the US side you should be fine. Depending on the load you could almost get away with 1x4 "hog-trough" for legs. 10' feet is right on the edge of safe "Legging within the foot print" of a platform.

Van

I am assuming by hog trough you mean a u-shaped leg made from three 1x4s. What do you see as the advantage to this over something like a 2x4? How would you attach it to the platform ( my simplified mental image of this is a framed platform with the 2x4 bolted to the frame ). It's not clear to me how you could easily bolt this in.

(or are we talking something other than a framed platform with legs).

John

So apparently a hog through is three pieces and a strong back is two pieces?

Gah.

Gah.

Ok, I admit I've never heard of a hog trough and I'm confused what it is used for. More information please! A picture or drawing of one in action would be great.

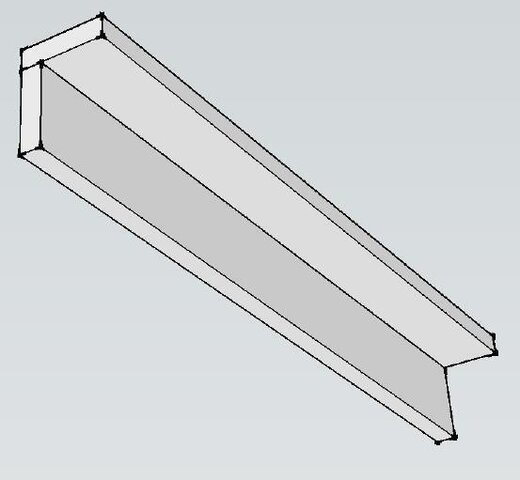

I haven't heard it referred to as a hog trough but we use them all the time. Essentially it's a pair of 1 by's joined in a right angle. It gives you the equivalent of dimensional lumber without the weight.

To put a deck on top, frame out the deck with a 1 by frame and rest it on top of the hog trough leg. Tie them together with plates, or another piece of hog trough nested on the inside so that it straddles the deck frame and the leg.

I've attached a quick sketch of a hog trough. I'm short on time for making a sketch of how it connects to a deck frame.

To put a deck on top, frame out the deck with a 1 by frame and rest it on top of the hog trough leg. Tie them together with plates, or another piece of hog trough nested on the inside so that it straddles the deck frame and the leg.

I've attached a quick sketch of a hog trough. I'm short on time for making a sketch of how it connects to a deck frame.

Attachments

Ok, I admit I've never heard of a hog trough and I'm confused what it is used for. More information please! A picture or drawing of one in action would be great.

In action I don't have.... but here ya go...

Its used in two ways... one is to stiffen the seams on flats. The other way is as legs. To build one, you need two pieces of 1x4 or 1x6 the same length. Line them up at 90 deg and glue and screw. They are extremely strong and cheap to build.

The reason its called hogs trough is that this is the same way you can build a cheap trough for pigs to eat out of. Throw it up on a stand at a 45 and you have a making for a good smorgasbord of slop.

Depends. What is the quality of the wood? Has the wood been stressed before? How tall is the leg?

Calculating a load on lumber is not an exact science like it is with steel.

Sorry to be so slow in responding, but it's looks like y'all got it all right without me. In Portland a right angle Strong-back is referred to as a Hog Trough, don't know why, just is. In school I learned that a Hog trough was three pieces, as gafftapegreenia, suggested. There are also T-Backs which are Hog Troughs with the right angle piece in the center. I've seen T-backs and Strong backs used quite often as stiffeners behind flats for both Movie and Theatrical sets.

They make very effective legs but I don't like to load them very heavily. Can I give you and exact load rating ? No. But, look at it this way. When using Hog-trough as a leg the structural integrity comes from a variety of different mechanisms.

#1 The screws going through the two pieces of 1x, and into the framing of the platform. By taking advantage of the inherent properties of the leg, those being the fact that it consists of two flat planes both of which can be secured to perpendicular framing members, you gain a lot of horizontal integrity, they resist side-to-side movement very well.

#2 The fact that you can screw through both faces into framing also means you have more mechanical fastening then you would have with a standard, single 2x4 leg.

#3 The manner in which a Hog-trough leg in manufactured increases the structural integrity of the material by a huge factor. The simple fact that you are adding a "back" onto the 1x4 means that both pieces are keeping each other from flexing longitudinally which translates to greater compression strength.

Now the drawbacks to Hog-trough legs are also multi faceted;

#1 While the compression strength is great most of the down-force support is accomplished by the fact that the top of the leg is resting against the bottom of the platform covering. Yes, some load is carried by mechanical fastening system, ie screws, nails., but the majority of the load is carried by the covering material itself. This can lead to issues of Plywood "peeling away from" the framing, especially in the corners, when the platform is loaded heavily.

#2 Most shops 1x stock is of low quality. The major issue here being that when Joe Shcmoe Wood Butcher goes to leg up a platform he starts slamming the screw in and splits the wood of the leg. Since you are very close to the end of the wood this can lead to splitting and cracking and there goes you shear force resistance.

#3 The footprint. Since you have an L shaped "foot" when using Hog Trough legs you have a very large surface area. This is good, in the sense that it spreads the load, bad in that it opens you up to a greater chance of encountering inconsistencies in the flooring. In other words you run a bigger chance of hitting a high spot in the floor. A good way to counter this is to chamfer the outside corners of the leg with a 15-30 degree angle after cutting it to length.

The Best Legging System I have ever seen? Well, outside of using a Knee Wall or Apple Box set up Like I use with Triscuits, a combination Compression leg Hog trough would be it.

Sorry to be long winded. Who Knew Hog Trough could be so facinating ?

They make very effective legs but I don't like to load them very heavily. Can I give you and exact load rating ? No. But, look at it this way. When using Hog-trough as a leg the structural integrity comes from a variety of different mechanisms.

#1 The screws going through the two pieces of 1x, and into the framing of the platform. By taking advantage of the inherent properties of the leg, those being the fact that it consists of two flat planes both of which can be secured to perpendicular framing members, you gain a lot of horizontal integrity, they resist side-to-side movement very well.

#2 The fact that you can screw through both faces into framing also means you have more mechanical fastening then you would have with a standard, single 2x4 leg.

#3 The manner in which a Hog-trough leg in manufactured increases the structural integrity of the material by a huge factor. The simple fact that you are adding a "back" onto the 1x4 means that both pieces are keeping each other from flexing longitudinally which translates to greater compression strength.

Now the drawbacks to Hog-trough legs are also multi faceted;

#1 While the compression strength is great most of the down-force support is accomplished by the fact that the top of the leg is resting against the bottom of the platform covering. Yes, some load is carried by mechanical fastening system, ie screws, nails., but the majority of the load is carried by the covering material itself. This can lead to issues of Plywood "peeling away from" the framing, especially in the corners, when the platform is loaded heavily.

#2 Most shops 1x stock is of low quality. The major issue here being that when Joe Shcmoe Wood Butcher goes to leg up a platform he starts slamming the screw in and splits the wood of the leg. Since you are very close to the end of the wood this can lead to splitting and cracking and there goes you shear force resistance.

#3 The footprint. Since you have an L shaped "foot" when using Hog Trough legs you have a very large surface area. This is good, in the sense that it spreads the load, bad in that it opens you up to a greater chance of encountering inconsistencies in the flooring. In other words you run a bigger chance of hitting a high spot in the floor. A good way to counter this is to chamfer the outside corners of the leg with a 15-30 degree angle after cutting it to length.

The Best Legging System I have ever seen? Well, outside of using a Knee Wall or Apple Box set up Like I use with Triscuits, a combination Compression leg Hog trough would be it.

Sorry to be long winded. Who Knew Hog Trough could be so facinating ?

I've always thought hog troughs were made out of two pieces but the CB Glossary told me otherwise.

When the shop here at school makes hog troughs we first run a healthy line of wood glue down the seam and then staple it together.

The nice thing about hog troughs is they really cut down on leg wobble.

When the shop here at school makes hog troughs we first run a healthy line of wood glue down the seam and then staple it together.

The nice thing about hog troughs is they really cut down on leg wobble.

Thanks guys, I have seen them used... just had never heard the term.

A nearby community theater uses Unistrut on the back of all their sets in a similar fashion. If you slide a piece of 1x2 inside the unistrut you can screw through the flat into the 1x2 and sandwich the steel to the flat. They run Steel up to the grid and bolt it to the floor. Their sets are rock solid and jacks are not necessary which is a huge bonus if you have a small backstage area. A very clever technique that I'm going to begin using this year myself. I'll post some pictures when I get a chance.

A nearby community theater uses Unistrut on the back of all their sets in a similar fashion. If you slide a piece of 1x2 inside the unistrut you can screw through the flat into the 1x2 and sandwich the steel to the flat. They run Steel up to the grid and bolt it to the floor. Their sets are rock solid and jacks are not necessary which is a huge bonus if you have a small backstage area. A very clever technique that I'm going to begin using this year myself. I'll post some pictures when I get a chance.

Similar threads

- Replies

- 14

- Views

- 4K

- Replies

- 23

- Views

- 4K

- Replies

- 0

- Views

- 570

- Replies

- 2

- Views

- 1K

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)