You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bump test motors

- Thread starterDagger

- Start date

RonaldBeal

Well-Known Member

Generally the point of the "bump test" is to insure that all of the motors are working. I typically bump one at a time, because it is very difficult to catch one not running in such a quick span. There should be enough margin that a slight imbalance in the load distribution shouldn't negatively affect anything. If you are right at the limit of weight capacity, you need to add more motors.

Individually. I start with bumping up, as the dynamic load increase is less. Then down, to make sure both directions work. I test motors every time I walk away from the pendant. One never knows during a load in or load out when a cable can become disconnected or damaged while others are working on or around the rig.

RonaldBeal

Well-Known Member

To add to what egilson1 said...

When truss is on the ground, I bump down first, then up, so I am not lifting the truss and then dropping it back down (on someones toes, or off of a cart. For load-out, I just bump down, because that is the only direction I need it to go. For all other moves, I bump in the direction I intend to go next. There is merit to checking both directions each time.

When truss is on the ground, I bump down first, then up, so I am not lifting the truss and then dropping it back down (on someones toes, or off of a cart. For load-out, I just bump down, because that is the only direction I need it to go. For all other moves, I bump in the direction I intend to go next. There is merit to checking both directions each time.

I do agree with bumping motors individually. But when the truss is being levlled and ending up with one motor taking all the weight?

Instance of leveing truss with a disto on the ground.

Truss is up in air , just tweaking for trim height and level: trussline with 6 motors . 1. Motor gets bumped up. - is this motor now not taking all the weight? While the rest 5 motors are slacking?

Instance of leveing truss with a disto on the ground.

Truss is up in air , just tweaking for trim height and level: trussline with 6 motors . 1. Motor gets bumped up. - is this motor now not taking all the weight? While the rest 5 motors are slacking?

tdrga

Well-Known Member

I'm being pedantic, but that one motor is only taking all the weight if the truss is vertical underneath it.

Anything more than just three hanging points in a straight line and you have a system in which small changes can have unexpected and large consequences. That's why you need to design a rigging system to take into account the "worst case" forces or use load cell monitoring. Bumping one motor a short distance (out of six motors) to level a truss should not be enough to compromise a properly designed rig.

-Todd

BillConnerFASTC

Well-Known Member

No. The tested motor still have has half plus the impact/acceleration which shouldn't be more than 10% or so, probably less.

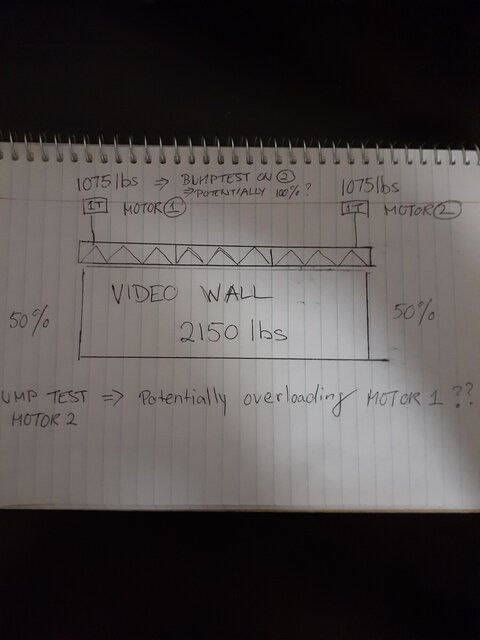

@Dagger This would only be true if all of the other motors were slack and supporting no portion of the load.See my drawing please

If truss has #2 1T motors . Video wall 2150lbs

Each motor is carrying a load of 1075lbs.

My quesion when bump testing , 1 motor takes 100% of weight and motor will be overloaded.

@What Rigger? and @egilson1 Comments??

Toodleoo!

Ron Hebbard

tdrga

Well-Known Member

I'm confused - your examples switch from a two motor system to a three motor system.

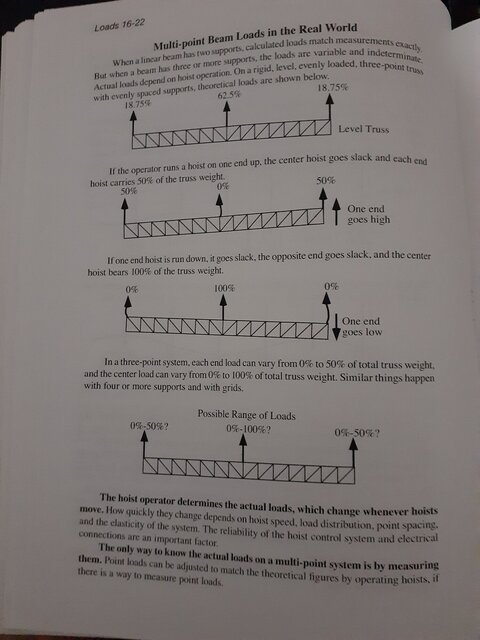

The example from Jays book shows a three motor system with an absolutely rigid truss system with no deflection. Yes- if one end motor goes completely slack, the center motor will become a pivot point and take all of the weight.

This is not the same as bumping one motor of a two motor system. In a two motor truss system, both motors share the load (not necessarily equally) unless the load is completely suspended underneath one motor.

-Todd

RonaldBeal

Well-Known Member

I do agree with bumping motors individually. But when the truss is being levlled and ending up with one motor taking all the weight?

Instance of leveing truss with a disto on the ground.

Truss is up in air , just tweaking for trim height and level: trussline with 6 motors . 1. Motor gets bumped up. - is this motor now not taking all the weight? While the rest 5 motors are slacking?

Even in multiple motor lifts, one motor will not take all of the weight. (well unless every other point completely fails, but that is another matter) Several factors are at play:

First, deflection allows some "play" so that non level structures do not shift "all" of the weight.

Second, a motor bumping up, will stop lifting shortly after exceeding its rated weight.

Additionally, motors rarely all run at the "exact" same speed. due to distibution of weight, more lightly loaded sections of a truss will go up faster than more heavily loaded. It is not uncommon for motors to get more than a foot out of level on a long lift. pretty common to stop raising the truss to re-level by eye on a long, unbalanced truss raise.

War story:

back in the mid 1990's was on a tour that had a large heavy octagon lighting rig. each of the eight corners of the octagon needed two 2-ton moters (on a spreader bar) to lift. Well one day we were taking the rig to trim, and the motor operator let go of the "go" button, but 4 motors kept going up.

He hit the E-stop, but those same 4 motors kept going up.

He physically unplugged the control pendant, but those same 4 motors kept going up. Meanwhile, myself, and a set carpenter both sprinted for the motor pd racks, and started yanking cam locks out of the rack until it stopped.

We discovered a design flaw in the distros, that allowed this issue if a link cable became partially unplugged. (We quit using those distros after this.)

By this point all of the weight was on the 4 motors that ran away, and the 4 opposite. The 8 in the middle were all slack. This is the reason safety factors exist. The octagon was a good 8 feet out of level. Throughout the ordeal, however, one motor, or even the 4 runaways never took all the weight.

BillConnerFASTC

Well-Known Member

More than two motors and the load distribution will vary widely. Its been shown with load cells. I can't find the video of Eilon Engineering showing this. IIRC Bill Sapsis was at the demo and was surprised just how uneven and ever changing the loading between hoists is.

But two - unless one goes slack - is pretty consistent sharing.

But two - unless one goes slack - is pretty consistent sharing.

What Rigger?

I'm so fly....I Neverland.

Hey Ron, thanks for the heads up. You'd have to go far beyond a bump test to put this "entire load on one motor" scenario into play, I think. The other questions this brings to mind is: if each motor is a 1 Ton, and the entire load did go to one hoist....why is this system designed to so easily go to a 1:1 design factor? I would definitely go for more motors. But I am also not sure I understand what the OP is laying out for us. Another reason we don't talk about how to rig stuff (too much) around here.@Dagger This would only be true if all of the other motors were slack and supporting no portion of the load.

@What Rigger? and @egilson1 Comments??

Toodleoo!

Ron Hebbard

You're comparing apples to bowling balls. The 3 point suspension is not the same as 2 point suspension.

The training I received was "one hoist at a time". It's easier to hear the motor run in many cases (although the new hoists are much, much quieter than an old Lodestar....) and observe it is running in the correct direction, than visually observe 1 motor out of several.I have always seen bump test with 1 motors...until recently i hear someone saying to bump all the motors to see which one isn' t moving.

Last edited:

Similar threads

- Replies

- 8

- Views

- 1K

- Replies

- 6

- Views

- 495

- Replies

- 12

- Views

- 1K

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)