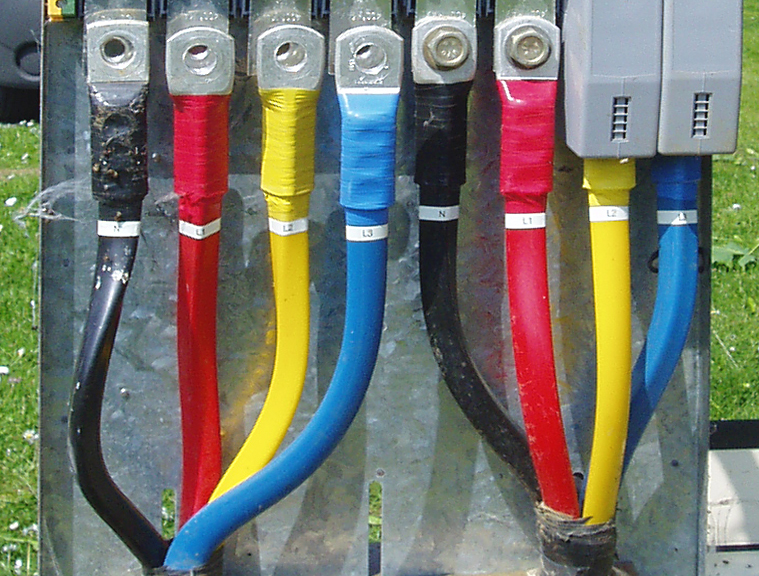

Seconded. I've done several shows where they feed hots in one side and G/N in the other. Provided you don't let monkeys play with distros, you're fine. (Okay, slight exaggeration, but really, as long as they are qualified to do it they won't make that mistake).I think we need to remember that single-pole connectors and single-conductor feeder systems are only for use by Qualified Personnel, per the NEC. Cam connectors can be thought of as "tool-less lugs", but the responsibility for the design and correct installation of the feeder system rests with the qualified person installing it, just as if it were permanent wire in conduit. Arrangement of connector rows and/or neutral ground sex in a feed-through rack would not be something that would be a problem for a Qualified Person, since they would clearly identify and mark each feeder set at both ends as to its function.

ST

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cam Turn Arounds

- Thread starterFooter

- Start date

Some history:

1. Cam-Lok E1016 connectors were first used in an entertainment application on Colortran 6 x 6kW portable dimmer packs, circa 1977. In order to attempt UL Listing, they needed non-intermateablility of hot, neutral and ground. This was at least 7 years prior to NEC recognition of single conductor feeders and single-pole separable connectors, with their associated connection-order rules. Without these NEC rules, UL made up some of their own: no intermateability of hot, neutral, ground. (Note that even today, the NEC makes no statement about non-intermateability of these specialized connectors).

2. Colortran used Empire Products E1016 males on the hots, an E1016 female on the neutral, and a female Palmgren Screw-Lok on the ground. The Palmgren Screw-Lok was a hideously expensive, long lead-time connector that used the same female neoprene housing as an E1016, but was not mateable with E1016. Another great feature: its cable boots only came in a vulcanized version, not the "Lektra-Link" style that is now standard on E1016. That meant:

--A vulcanizing press

--Vulcanizing tape

--Gooey vulcanizing lube

--At least 10 minutes curing time per connector

--No field installation or removal, unless you had a vulcanizing press in your workbox

Palmgren Screw-Lok connnectors

Welcome to Integro

3. Production Arts owned a bunch of those Colortran packs, and after extreme frustration with the Palmgren Screw-Lok's, we changed them out for female E1016's. Our logic: better to guarantee no intermate of hots with neutral and ground. That arrangement became our standard on touring gear, and I guess our logic caught on with some other rental companies-- but there were notable holdouts such as Vanco.

ST

Got one of them presses, took years to get rid of the last of these plugs but I think they are all out of the system now. Didn't even like old style CamLoc's in not really reliable for being removable, easier and cheaper in a dependability way to just felet the fish/plug and get rid of it. Never saw the different ground before though - was probably a carpenter back than and avoided stuff that went spark in the night.

Thinking about modifying the vulcanizing press so as to make stringers for our kabuki wiring and lamp stringers neither of which are either available on the market suficient for the specific needs I want for them in function. At the moment as has been done for about 25 years now I still have to do it in a non-code compliant way for the Kabuki's and even if improved on the lamp stringers, still more hack than I like... Plug as an interconnection device type of thing on the kabuki stringer as with modifying a plug type rules, also in only able to use 14ga wire for the interconnection receptacles. It also limits the amount of kabuki's that can be dependably done in a circuit due to voltage drop problems if you get over 15 or 18. This as opposed to lamp construction like stringers that's 18" on center and three circuit wire rope supported?

Since nobody will make such things, long term project for me is to make my own. Granted the idea has been on hold for ten years now... but perhaps in the next ten years I'll get to it.

Or wait a minute... Think I have a whole milk crate of the brass used for the grounds... Thanks, should free up some well needed space in a well packed cabine once I recycle them.

Speaking from experience (I do about 70 hotel shows a year between two of the tours I oversee) I would guess that about 60% of the venues my shows travel to have Bare-End Tie-Ins. For reference we have contracts with Hyatt's & Westin's and only go to ballrooms & halls over 12,000sf. The other 40% are Cam's, and of them the majority (75%) DO reverse their Neutrals & Grounds on 200A & 400A services (which is what we book). We have banded & unbanded 4/0 (depending on the show) so Cam-turns are a neccessity. Add in the "forgetful" stagehand, "unknowing" stagehand, and "pissed off" stagehand, and they keep my road crew from committing suicide!

On another topic...I like to see just how badly hotel electricians tie in tails...Let me tell you I have seen some SCARY stuff....E-taped & zip-tied bus bar's seem to be a favorite of hotel electricians. I once even saw an electrician who couldn't get the 4/0 into his bar, so instead of cutting back some of the copper (which come on we all do in a bind) He instead LEFT THE HEX KEY IN THE TERMINAL SCREW, and I kid you not split the copper around the metal of the hex key and "twisted" off the end on top of it. I took a picture and printed it, then gave it to the crew-chief after us..."Good Luck!" lol.

Amazing, Fascinating! Black oxide on most T-Handles don't conduct well to start - this amongst other things. That I will have really stopped the show over I think until corrected. Seen the multi-hole trick before where the feeder is divided up in strands between like two or four holes to a lug, never thought of that option before - guy must have been brilliant in his own way. What size wire nut to use might come to mind as a starting talking point with the person doing so.

On the "at times having to shave down", and assuming you are well under the capacity of the cable draw, I assume given the "skin effect" it's the inner core conductors cut away for doing this? That's if I had to would do so, anyone else?

... Also starting to switch to the Bates/Marico hard plastic female connectors over the preferred ECT Leviton line. Tired of the females wearing out where it hits the brass. TBA how well the hard plastic holds up but given labor and materials needed to swap out the rubber based receptacles, worth a try. ...

Interested in hearing your opinion on these. I've been a big advocate of them for a couple of years now. Will never go back to the rubber-jacketed variety if I can avoid it.

400 Amp/600 Volt Female Inline Brass DSS - all colors | Marinco

400 Amp/600 Volt Male Inline Brass DSS - all colors | Marinco

Question (to anyone): When would using a gray-jacketed (see "J" below) Cam-Lok be appropriate?

Thanks for the history lesson, Mr. Terry. FWIW, I don't recall ever turning around Tweco's.

Tweco's I thouht were another totally different plug type? Got a set of them on my wall of shame.. or at least in the attic with the aditions to it in having to take it apart for space and needing to make a larger wall. Hmm, Wall of shame too small for additions later or Hall Tree and Wine rack... given a domestic situation... went for the other two.

Work don't want a wall of shame - would look bad should clients pass by it - might get the wrong impresson, even if at least half of it came from what was found at work. Most of the rest either antique "interesting" stuff like porcelain outlets or stuff like why you can't do Zip cord in the grid example.

Interested in hearing your opinion on these. I've been a big advocate of them for a couple of years now. Will never go back to the rubber-jacketed variety if I can avoid it.

Question (to anyone): When would using a gray-jacketed (see "J" below)

Saw an origional deign for them and was skeptacle especially for touring purposes by way of say truck headed into the Northern States or Canada in doing the tie in. It's plastic and might have problems with becoming britle should it get dropped. This plus perhaps also thermal issues if really cold and a high amperage load or a problem in getting really hot - really fast in perhaps shattering or at least being a bit brittle.

Beyond I didn't like them for design reasons and my guys in now using them really don't like them. T/S type of thing to my guys in me looking to save money due to the failings of the rubber on ECT connectors I like and unless really pressed won't substitute for. Say if Leviton isn't up to snuff for delivery in time as often happens when I really need a lot of them. Main reason I'm play testing them now is I got really tired of at the last minute before the cable goes out on a show while busy, having to re-task my guys normally also working on other gear for that show or one of our special projects often last minute and behind schedule in loosing a guy or even make me if best available.. Someone has to replace the CamLoc's to some feeder cable needed for a show is a frequent thing in the cable puller guys doing their job by way of inspecting the cable. Really is an amazing thing that the newest people to the company are doing their job so well, and a great thing that SOP in inspection of what's going out is doing so well they note such things.. but really a pain in the rear when I'm busy otherwise.

Not much about expense - fairly cheap at OEM cost the Leviton brand, more about even if it only takes say 15 minutes to change a plug, when prepping a show, often it's not just one but a bunch to replace normally as happens with multiple tie-in's. Loosing a guy when busy to fix stuff failiing - no matter how old that's caused by dropping the plugs without any other excuse... I'm play testing a hopeful this hard plastic Bates perhaps better product - this even given my concerns. My guys understand why and will get over it in not liking these receptacles as much. Perhaps with time and if they work out they will even like them.

Primary concern so far is with the female side. If it works out and they begin to like them better we will swith to also the male side also in standardization. This in me just having finished making a five color two size = basically Pez dispensor magazine cart for ETC type plugs. Stores about 20x plugs/connectors of each of the five main colors. Atop it origionally was a tray that stored the rest of the parts. Was too heavy and broke. Instead we made a new drawer elsewhere for such parts.

Hopefully if we switch brands, the Pez dispensor will work better with the plastic plugs - the rubber ones get hung up in the works otherwise with the ECT in not working out so well for such a cart. My boy's also hate it even if liking the concept. Pez disensor for CamLoc plugs with all parts needed to assemble at the top of the cabinet... way cool concept. Just needs a bit more development and if it works to the Bates version.. it would be a crash cart again given the brass is already installed in not being a top heavy upper lid.

Havn't sent out much in at least the past six years for six wire or found any vendors that is doing grey yet, but did ask over the year's in now asking again... who's making grey CamLoc's??? Not that going grey is necessary but it is really good concept and might solve problems with our cable puller's manager by way of... got these single conductor feeder cable hanging about... can I get rid or them or send them to "Ship" in making into a useful cable looms? Immeditely realized that these individual conductor cables were part of the past six wire double ground system we used to have some of. Hasn't been used in years and all six wire cable has been made five wire since than, but still I saved the second neutral as ready to go as normal. That second neutral was what he was seeing I think.

Personaly I'm a fan of six wire cable in concept. Given most shows are 208v on the other hand... not needed. Save one or two of these cable sets just in case though.

Last edited:

JD

Well-Known Member

Question (to anyone): When would using a gray-jacketed (see "J" below)

What I remember, and I can not find a current reference:

White = Bound neutral

Gray = Non-bound neutral

In other words, on a wye transformer feed where neutral and ground are connected at the transformer or bound at the service entrance; green, white, black, red, blue.

On the same wye, where the neutral and ground are not bound; green, gray, black, red, blue.

Learned that as a teen (many, many years ago) and could not swear to accuracy.

PS: I have no idea under what circumstances you would have a non-bound neutral!

What I remember, and I can not find a current reference:

White = Bound neutral

Gray = Non-bound neutral

In other words, on a wye transformer feed where neutral and ground are connected at the transformer or bound at the service entrance; green, white, black, red, blue.

On the same wye, where the neutral and ground are not bound; green, gray, black, red, blue.

Learned that as a teen (many, many years ago) and could not swear to accuracy.

PS: I have no idea under what circumstances you would have a non-bound neutral!

Question (to anyone): When would using a gray-jacketed (see "J" below)

What I remember, and I can not find a current reference:

White = Bound neutral

Gray = Non-bound neutral

In other words, on a wye transformer feed where neutral and ground are connected at the transformer or bound at the service entrance; green, white, black, red, blue.

On the same wye, where the neutral and ground are not bound; green, gray, black, red, blue.

Learned that as a teen (many, many years ago) and could not swear to accuracy.

PS: I have no idea under what circumstances you would have a non-bound neutral!

By my understanding grey is the second color for neutral wire as acceptable by code now in general for all use. Wish ther were a third color but there in general - no rules about bonding, grey is the way and often in grey darker than white I'll use it say for a un-sleeved constrution stringer for a second neutral or for other purposes say in some soco box in differenturating the circuits.

STEVETERRY

Well-Known Member

Interested in hearing your opinion on these. I've been a big advocate of them for a couple of years now. Will never go back to the rubber-jacketed variety if I can avoid it.

400 Amp/600 Volt Female Inline Brass DSS - all colors | Marinco

400 Amp/600 Volt Male Inline Brass DSS - all colors | Marinco

Question (to anyone): When would using a gray-jacketed (see "J" below) Cam-Lok be appropriate?

Gray is allowed for Neutral by the NEC, and could be more stylish!

ST

JD

Well-Known Member

Interesting IMSA article about the NEC and wire colors:

NEC Wire Color......

Quote:

Comment: Often 6 AWG and 8 AWG conductors are reidentified in the field with white phase tape. This is a NEC violation, although it is often overlooked. Because 4 AWG and larger can only be reidentified with “white markings”, it would be violation to reidentify with gray. This was an oversight in the 2002 NEC revision and will likely be corrected for the 2005 edition.

Identification of a 277 V grounded conductor can be done using a gray conductor if desired. However, if two or more grounded conductors from different systems, such as 120/240 and 277/480, are present see the requirement in (D) below.

(Scroll down a bit to get to the section. Also covered is the BOYG coding)

What about a System Color Code?

The question often comes up about using black/red/white for 120/240 V single phase and brown/orange/yellow/gray (BOY) for 277/480V three phase and similar. There used to be a color code requirement in the NEC, but it was removed in the mid-70’s. Many proposals have been made to require a color code requirement, and the code making panels response is “We don’t want you to look at wire color and assume because its red it is 120 to ground. We want you to test it and be sure”. There is nothing stopping an agency from adopting a color code standard if it can be enforced. Often what gets installed is what is on the truck. If a color code standard is used for multiwire branch circuits, then the ungrounded conductor identification must be posted at each branch circuit panel board, see Section 210.4 Multiwire Branch Circuits, (D) Identification of Ungrounded Conductors. Using gray for a 277 V grounded conductor is acceptable only if it is not present with another system grounded conductor. See discussion under Article 200.

NEC Wire Color......

Quote:

Comment: Often 6 AWG and 8 AWG conductors are reidentified in the field with white phase tape. This is a NEC violation, although it is often overlooked. Because 4 AWG and larger can only be reidentified with “white markings”, it would be violation to reidentify with gray. This was an oversight in the 2002 NEC revision and will likely be corrected for the 2005 edition.

Identification of a 277 V grounded conductor can be done using a gray conductor if desired. However, if two or more grounded conductors from different systems, such as 120/240 and 277/480, are present see the requirement in (D) below.

(Scroll down a bit to get to the section. Also covered is the BOYG coding)

What about a System Color Code?

The question often comes up about using black/red/white for 120/240 V single phase and brown/orange/yellow/gray (BOY) for 277/480V three phase and similar. There used to be a color code requirement in the NEC, but it was removed in the mid-70’s. Many proposals have been made to require a color code requirement, and the code making panels response is “We don’t want you to look at wire color and assume because its red it is 120 to ground. We want you to test it and be sure”. There is nothing stopping an agency from adopting a color code standard if it can be enforced. Often what gets installed is what is on the truck. If a color code standard is used for multiwire branch circuits, then the ungrounded conductor identification must be posted at each branch circuit panel board, see Section 210.4 Multiwire Branch Circuits, (D) Identification of Ungrounded Conductors. Using gray for a 277 V grounded conductor is acceptable only if it is not present with another system grounded conductor. See discussion under Article 200.

Last edited:

Interesting IMSA article about the NEC and wire colors:

NEC Wire Color......

Quote:

Comment: Often 6 AWG and 8 AWG conductors are reidentified in the field with white phase tape. This is a NEC violation, although it is often overlooked. Because 4 AWG and larger can only be reidentified with “white markings”, it would be violation to reidentify with gray. This was an oversight in the 2002 NEC revision and will likely be corrected for the 2005 edition.

Identification of a 277 V grounded conductor can be done using a gray conductor if desired. However, if two or more grounded conductors from different systems, such as 120/240 and 277/480, are present see the requirement in (D) below.

(Scroll down a bit to get to the section. Also covered is the BOYG coding)

What about a System Color Code?

The question often comes up about using black/red/white for 120/240 V single phase and brown/orange/yellow/gray (BOY) for 277/480V three phase and similar. There used to be a color code requirement in the NEC, but it was removed in the mid-70’s. Many proposals have been made to require a color code requirement, and the code making panels response is “We don’t want you to look at wire color and assume because its red it is 120 to ground. We want you to test it and be sure”. There is nothing stopping an agency from adopting a color code standard if it can be enforced. Often what gets installed is what is on the truck. If a color code standard is used for multiwire branch circuits, then the ungrounded conductor identification must be posted at each branch circuit panel board, see Section 210.4 Multiwire Branch Circuits, (D) Identification of Ungrounded Conductors. Using gray for a 277 V grounded conductor is acceptable only if it is not present with another system grounded conductor. See discussion under Article 200.

Fascinating and terrible in the same way for me. So what is said above, me in the use of grey colored wire for use as a second ground wire ain't code. Say I'm doing a six circuit Soco 208v Wye and want to for no other reason than mark which circuit it is if doing black/red/blue for the hots, and want at least a different color for the neutrals within a box for a difference between say circuit one and four... gray wire isn't an option for use.

Also, thought that code got changed to the better in being able to mark the last say 2" of a cable for what conductor use it was - meaning tape or even paint marker - this to the extent to even using a silver sharpee to mark a neutral where the other was black inside of non-user servicable gear.

While I understand the need for and concepts above, I thought grey was the way in at least getting another ground color. Pink perhaps at some point say - this given I'm color blind and "Brown is ground" in reference to Euro cable was told as a joke to someone at work who than wired up such gear by mistake. Yea... that blew up a few hundred dollars of gear. On the other hand, blue is neutral or hot? NEC.. sort of a I before E except after C type of code or solving problems?

epimetheus

Well-Known Member

In the power industry, gray is often used for the neutral of a circuit that is color-coded orange, yellow, brown. I won't denote that color-coding only to 480V because I've seen it used at 5kV and other voltage levels as well.

On a side note, I completely agree with the code panel's reasoning of not assuming anything based on a particular color. In some 15kV systems, the phases are marked red, white, blue. I dare you to assume that white is a neutral!

On a side note, I completely agree with the code panel's reasoning of not assuming anything based on a particular color. In some 15kV systems, the phases are marked red, white, blue. I dare you to assume that white is a neutral!

JD

Well-Known Member

What I found fascinating is that "Green" can be a hot !!! (Exemption for traffic signal cable that is designated for traffic signal use.) Guess you can't count on anything, so ALWAYS measure. I suspect that many of these instructions pertain to enclosed systems as I suspect nobody is going to cut the last few inches of their 4/0 SC cable and replace the insulation with green tape!

Yep! Black as neutral! Kind of colorful....

Big Boss wants to make universal power supplies for gear touring the world. Slight problems it would seem beyond transformers and indicator lights in converting between 120 and 240v.

Any hope the NEC and USITTwill beyond believe there also problems with electronics wire code, any hope of a international convention so as to straighten out wire coding? Fascinating and never saw the above before. At least they are marked and perhaps that's how I'll also start marking my cable or power supplies. L1 verses Ground or N for neutral. On the 240 verses 208v world... Grey a second neutral for the more normal 208v system is or isn't a second ground color permissible?

Similar threads

- Replies

- 7

- Views

- 509

- Replies

- 0

- Views

- 716

- Replies

- 6

- Views

- 2K

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)