rustystuff

Member

No apologies needed to me in not having any badges...

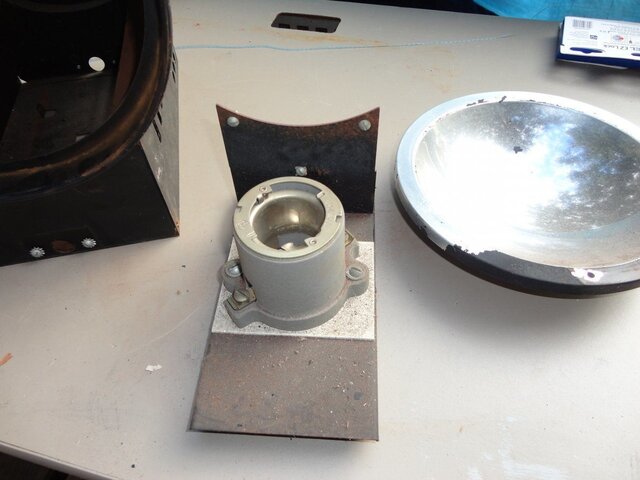

Socket in good shape - seen that and under that not so good. Recommended full stipping of the fixture and re-wiring of it but each of us is a TD onto ourselves and what you do I don't and what I do you don't. We all come together on a basic sense of safety though as well expressed in ready to do so.

Whitish pad = asbestos pad under the lamp socket, this unless coming from me as ceramic fiber as similar but not asbestos in replacement pad. Lots of asbestos about an old light. Per percentage of what one might see on a water pipe or fire curtain - certaily not as much. On the other hand if even survived the like 20 year exposure - new exposure to it ain't making you super hero in resitant to asbestos - just means you like me been lucky over the years. Next chance exposure to it is your nexxt 20 years later conformation that that last exposer wasnt cancer related to you if you didn't get it.

Asbestos a bad thing in only like 15 to 20 years following exposure to it will you know if you were effected by it.

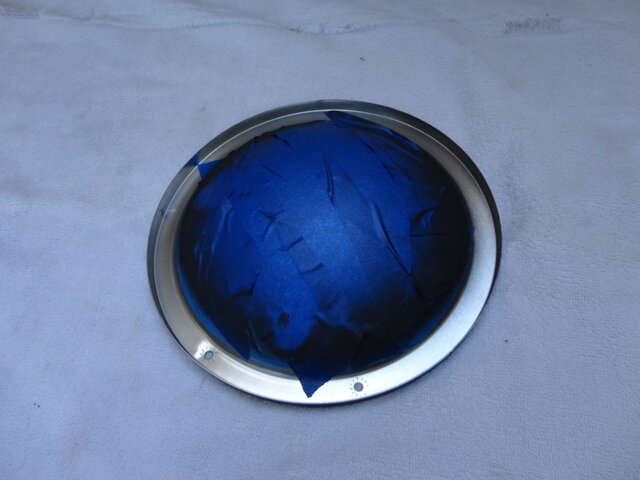

My Whitish pads are ceramic pads and I replace all asbestos I find.

Thanks AGAIN, ship! Tell me more about the ceramic pads you use, i.e. source, cost, etc. I'm guessing the purpose of this pad is heat insulation? Further visual examination shows that this pad seems to be the only asbestos left in this fixture. My plan is to begin the teardown of this 3413 this weekend. (SWMBO permitting, of course!)