SweetBennyFenton

Active Member

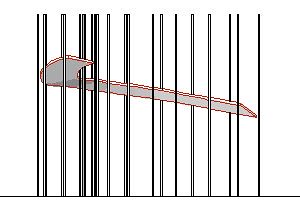

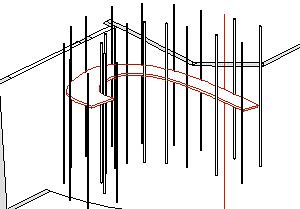

Hello all. I'm currently working on a show that will require a curving raked platform and I was wondering if anyone had any experience with them before.

It's a bit of an "C" curve at about a 15 Deg. rake. The whole thing is about 24 feet long. I can't just build the thing flat and then tilt it because it needs to be level from one side to the other as you walk along it..

So, long, curving, raked walkway build on a college theatre budget. Anyone?

It's a bit of an "C" curve at about a 15 Deg. rake. The whole thing is about 24 feet long. I can't just build the thing flat and then tilt it because it needs to be level from one side to the other as you walk along it..

So, long, curving, raked walkway build on a college theatre budget. Anyone?