TupeloTechie

Active Member

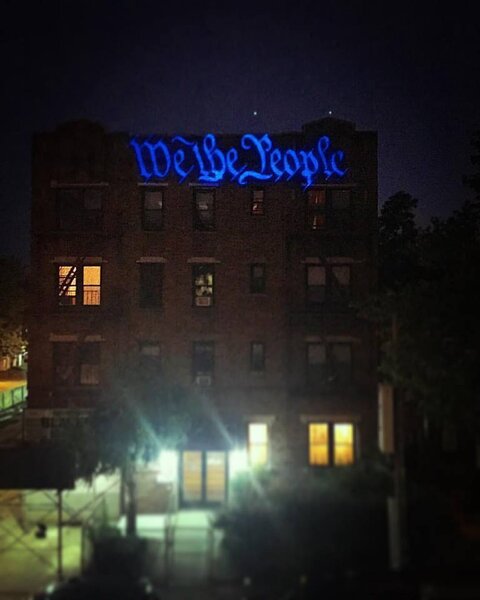

In a previous post I explored using my silhouette craft cutting machine to make vinyl gobos for LED based lekos. I've had great results, in both a Strong Neeva and Colorsource Spot. Below is a vinyl gobo in a Colorsource Spot I projected in celebration of July 4th. Ran fading between Red, White, and Blue for around 8 hours with no loss of quality.

I've recently used the machine to help etch shot glasses for opening night gifts, and the results got me thinking about using glass etched with this Armour Etch Cream to make textured glass gobos, as I've always enjoyed playing with Rosco's textured glass range, but haven't ever had the budget to use multiples. These would be for 575w Source Fours, not LED.

I'm assuming I would need some sort of special heat resistant glass? It's possible that the etching cream wouldn't even work with it, but I though someone on here might be able to point me the right way.

Thanks!

I've recently used the machine to help etch shot glasses for opening night gifts, and the results got me thinking about using glass etched with this Armour Etch Cream to make textured glass gobos, as I've always enjoyed playing with Rosco's textured glass range, but haven't ever had the budget to use multiples. These would be for 575w Source Fours, not LED.

I'm assuming I would need some sort of special heat resistant glass? It's possible that the etching cream wouldn't even work with it, but I though someone on here might be able to point me the right way.

Thanks!