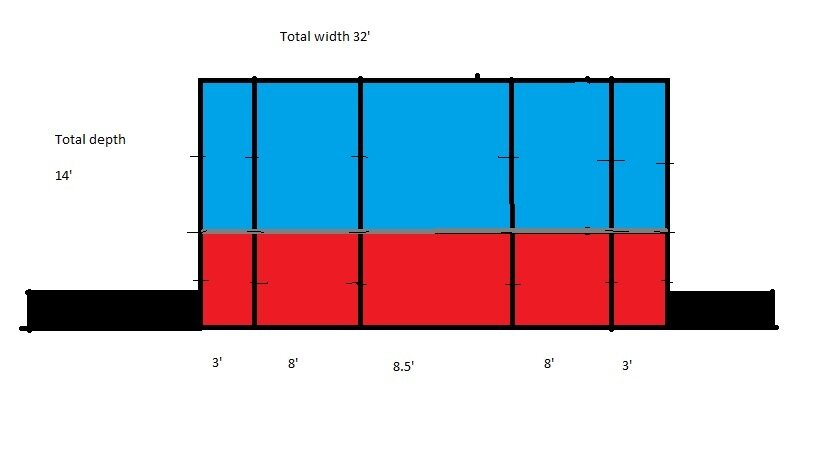

For an upcoming show I have to create an elevated area 8.5' off the ground that is 32' w x 14' d. This area will be use for a 9 piece orchestra (roughly 32'x8' blue area of picture below) and space utilized by actors (32'x6'). There will be dancing in the show (don't know how much will take place on that second level, but I'm planning for it anyway).

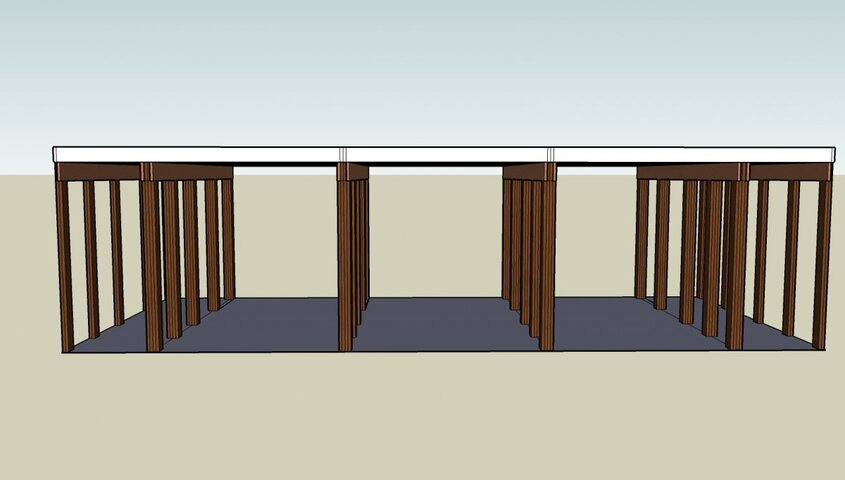

The structure underneath needs a 8.5' span in the middle, two 8' spans to either side, with the remaining 3-4 feet outside them simply completing the remainder of the 32'. The three middle spans will be used for set pieces that will move on and off from under the structure, so those spans can not have any legs in the middle. The middle 8.5' will have a single unit that will never change, but I'm hoping to utilize the ability to change a few pieces in and out of the two 8' spaces.

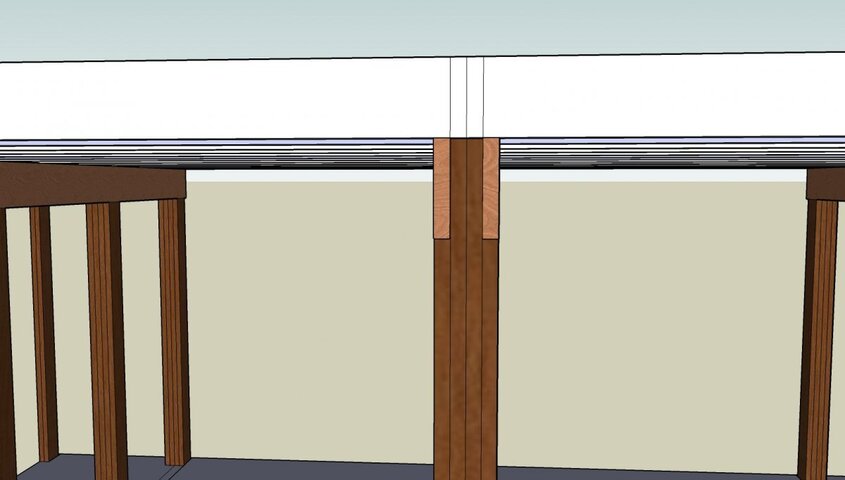

I plan on minimally having legs/posts for the structure where the black tick marks are. Every 4' for the orchestra area and every 3' for the actor space. I could possibly use stud walls for the sides of the 8.5' section. If I do "legs" they'll be multiple layer 2x6 compression legs, and bolted in to the headers/beam. Don't want to use 4x4 as they never seem to not warp after being stored for later use. I figure 3 2x6s gives you a

Upstage framing I will laterally brace as needed, but the downstage portion will essentially be "wedged" between a concrete proscenium (our proscenium is 16' from the front of the stage) so it won't move laterally at that edge even if it wants to.

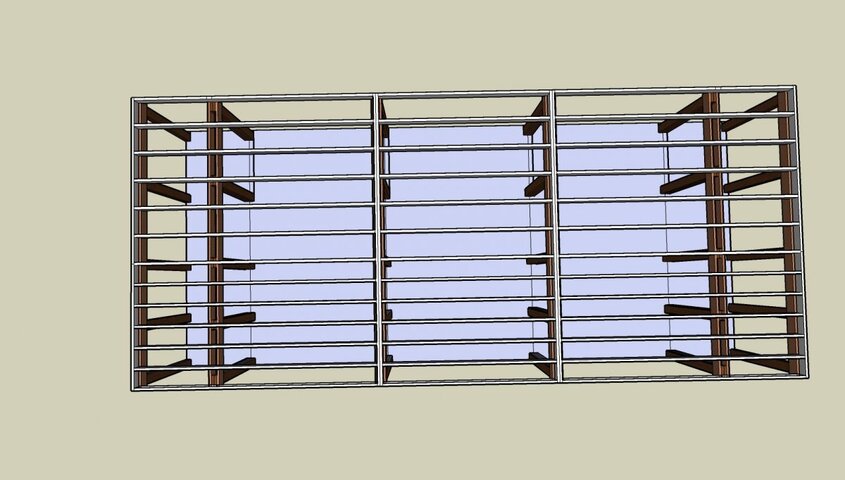

I have no issue switching to 12' on center joists for the actor portion to account for live load, but I'm still not sure how beefy I need to go. Sure you always want to air on the side of caution, but I don't want to build something that will be up for 3 weeks that could out-survive the building it's in. The joists will be decked with 3/4 rated ply.

Should I be using 2x8's for the longer span joists? (I think 2x6 is at the end of it's span rating at 8.5', even at 12" on center) Should I then be using 2x10's for beams? Or can I use 2x8's if I'm using stud walls instead of legs and joist hangers?

Recommendations greatly appreciated. As I said as always going to air on the side of caution, but I don't want to build (or more precisely spend the money on) something that could be done another way.

Thanks

The structure underneath needs a 8.5' span in the middle, two 8' spans to either side, with the remaining 3-4 feet outside them simply completing the remainder of the 32'. The three middle spans will be used for set pieces that will move on and off from under the structure, so those spans can not have any legs in the middle. The middle 8.5' will have a single unit that will never change, but I'm hoping to utilize the ability to change a few pieces in and out of the two 8' spaces.

I plan on minimally having legs/posts for the structure where the black tick marks are. Every 4' for the orchestra area and every 3' for the actor space. I could possibly use stud walls for the sides of the 8.5' section. If I do "legs" they'll be multiple layer 2x6 compression legs, and bolted in to the headers/beam. Don't want to use 4x4 as they never seem to not warp after being stored for later use. I figure 3 2x6s gives you a

Upstage framing I will laterally brace as needed, but the downstage portion will essentially be "wedged" between a concrete proscenium (our proscenium is 16' from the front of the stage) so it won't move laterally at that edge even if it wants to.

I have no issue switching to 12' on center joists for the actor portion to account for live load, but I'm still not sure how beefy I need to go. Sure you always want to air on the side of caution, but I don't want to build something that will be up for 3 weeks that could out-survive the building it's in. The joists will be decked with 3/4 rated ply.

Should I be using 2x8's for the longer span joists? (I think 2x6 is at the end of it's span rating at 8.5', even at 12" on center) Should I then be using 2x10's for beams? Or can I use 2x8's if I'm using stud walls instead of legs and joist hangers?

Recommendations greatly appreciated. As I said as always going to air on the side of caution, but I don't want to build (or more precisely spend the money on) something that could be done another way.

Thanks