Bubby4j

Active Member

We have a poorly designed stage at church, in that it's impossible to reach the things above it (lights, projector screens) without us renting a lift that sits in front of the stage and extends to over the stage, even then there's parts we can't reach.

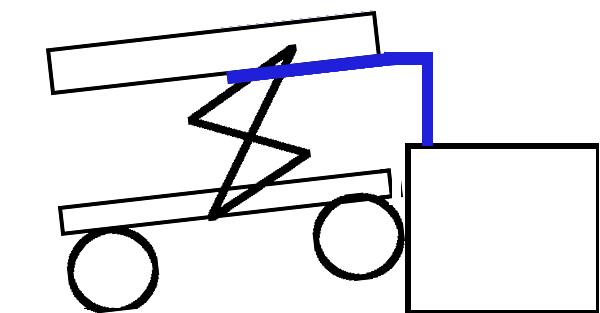

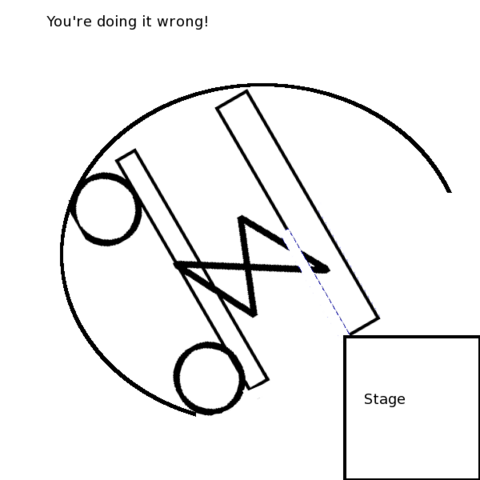

We already have a scissor lift, but no way of using it on the stage because it's almost 5' above the ground and there are no ramps.

What I'm thinking about, assuming that our stage is capable of bearing the load of our lift, is building some kind of a portable ramp to drive the scissors lift up onto the stage.

I've calculated from the maximum grade the lift can safely drive on retracted, and the height of the stage, that the ramp would have to be about 20 feet long.

How can I build a fairly portable ramp like that? Would it even be possible? It'd need to be able to support the lift's (probably) weight of 1-2 tons. (not completely sure on the model of our lift, I'd need to check)

I've googled and all the ramps I've found for cars only end up going 1' above the floor.

We already have a scissor lift, but no way of using it on the stage because it's almost 5' above the ground and there are no ramps.

What I'm thinking about, assuming that our stage is capable of bearing the load of our lift, is building some kind of a portable ramp to drive the scissors lift up onto the stage.

I've calculated from the maximum grade the lift can safely drive on retracted, and the height of the stage, that the ramp would have to be about 20 feet long.

How can I build a fairly portable ramp like that? Would it even be possible? It'd need to be able to support the lift's (probably) weight of 1-2 tons. (not completely sure on the model of our lift, I'd need to check)

I've googled and all the ramps I've found for cars only end up going 1' above the floor.