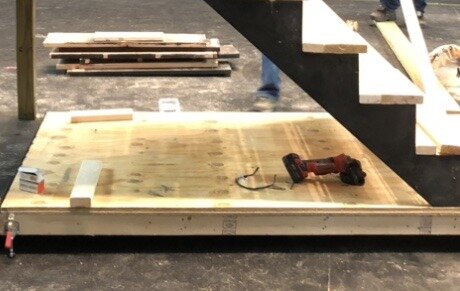

I've often topped

stock platforms with 440 with and without hardboard on top. It isn't always the right thing, just another trick in the bag.

It does help deaden

foot strikes on top but not so much the drumming resonance underneath. I've considered the possibility but not yet had the need to try for better/different performance by skinning the bottom of a

platform with it instead or in addition to the top.

Like Josh says, it can be a useful top layer and takes a variety of treatments well, which can also improve durability. Sure, don't

roll your grand piano or fully loaded

pallet jack over it even with a hardboard layer on top, but that kind of traffic is pretty rarely coupled with a need to deaden footsteps in my experience. I can't think of a time I've needed to

build for such a

point load and thought "gosh I wish I could do

Homasote here". Two coats of paint tends to be plenty of durability for short duration, light traffic, other than at exposed edges where footsteps can chew it up and cause some slipping and

tripping concerns. At step edges I've sometimes just gaffed or dutchmaned the

edge and other times done a wood nosing.

I keep enough sheets in

stock to match

platform stock plus a little. It lasts a long time because we keep most sheets whole or cut into 4x4s and 2x8s to match

stock plats. Plus, when you're skinning it with something else it doesn't have to be pretty - you can piece it together with whatever weirdo scraps you've got.

The other really nice thing about using it over the top of a

platform system is that it does a great job of easing any inconsistencies in the

platform surfaces. Got some gnarly old

stock lids with paint globs and random old fasteners hopelessly stuck on not remotely flush? A little twist in a frame? Or one frame freshly built from wood that sat outdoors in the rain for a week before it got delivered, trying to rest next to another frame that's four or fourteen years old, bone dry and 1/8" thinner? A perpendicular layer of 440 is soft enough to, sometimes with a little convincing, compress around all those obstacles considerably better than just a 1/4" skin of something denser. Got to be careful with screw depth adding hardboard on top though because of the softness - it can leave you with noticable puckers where screws compressed the

Homasote too much.

Yes, the dust is an awful nuisance and a respiratory concern just because it is so fine and plentiful. The

MSDS is not intimidating, but any dust that fine and light is a bad thing. I've never encountered anyone having any skin reaction though. Really good dust extraction (Festool...) helps but some is getting in the air no matter what.

Unless you cut and shape it with utility knives and other very sharp

hand powered blades, which takes about the same time when you factor in near zero cleanup versus the seemingly eternal ash cloud you get from

power tools. It's not too bad, especially if the appearance of the cuts isn't critical. I like to score both sides - one to two passes each - and

snap it off, then clean the snapped

edge with a sharp blade if needed. Sometimes I don't even bother scoring both sides - like cutting drywall.