Certain brands and ages of lot numbers of fixtures or lamps are a little less friendly with each other in standards. Modern days, all should be fine but in the past - Sch.40 pipe and rubber mallet to install lamps at times on a weekend extra hours at times years back.

Great

fixture, quality control has gone up both for standard in lamp and

fixture since

introduction. Suspect these are earlier fixtures with later lamps.

Beyond installing, "lamp looked

clear" how did the pins to that lamp look? That which connects to the

socket of the

fixture? Very often from moving light lamp to

conventional fixture, a virus of bad lamp into good

socket or bad

socket onto good lamp gets done in two other options for the situation all also bad.

Lamp looks

clear, pins crap, transferrs bad conductivity to a new

socket in what was bad

in one fixture, the same lamp in now both just made both fixtures bad by way of we now have bad conductivity and by way of resistance destroyed another lamp

socket. This in changing lamps between sockets as opposed to just plain putting putting perfectly good lamps into bad sockets and seeing them again in a few weeks - thus complaining "bad lamps"?

Ought to get our money back on the lamps or tech people installing them as presented often the latter and my thoughts the after.

I digress, possible with lot number, a certain brand of lamp and lot of

fixture will be harder to pund home than others in

fitting well. Clean that lamp after installing with a lint free

denatured alcohol whipe - this no matter if you think you touched or now. Someone else touch it even if new? Exploded after that to work on.

Anyway what I suspect in happening.

Also and even more suspect

globe damaged while installing or sweat/dirt left on the

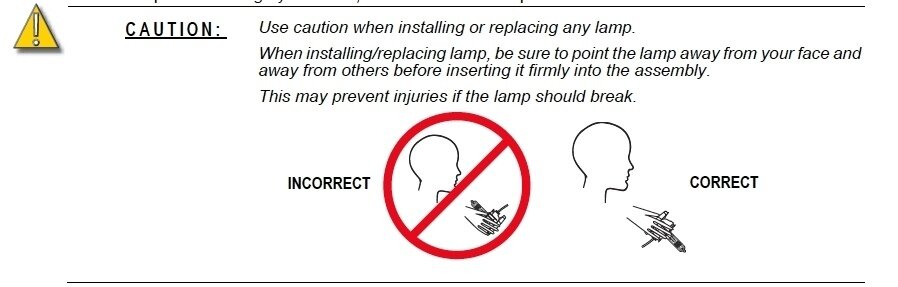

globe "quartz glass" that should not be exposed to it. Guy in photo not wearing gloves and no mention of cleaning the glass after install without gloves. Finger .... touched, the lamp while installing??? Possible?