So I could probably just figure this out tomorrow, but I thought this would be an interesting topic for the booth, and has some educational merit.

So today I was running XLR (20 minutes before the house opened!) with the ME for a newly home-brewed cue-light system. It was pretty interesting. A little DC power supply into a hobby box, with unknown electronics/wiring inside, two toggle switches and two XLR outs. The XLR was run from the hobby box to the cue-light location, and a small adapter was attached to the end of the run, also home-brew. He took a bare connector, and wired it up with the LED sticking out the hole where the cable would be...

Looked like a pretty nice little setup, and cheap/easy considering most theaters should have the parts on-hand.

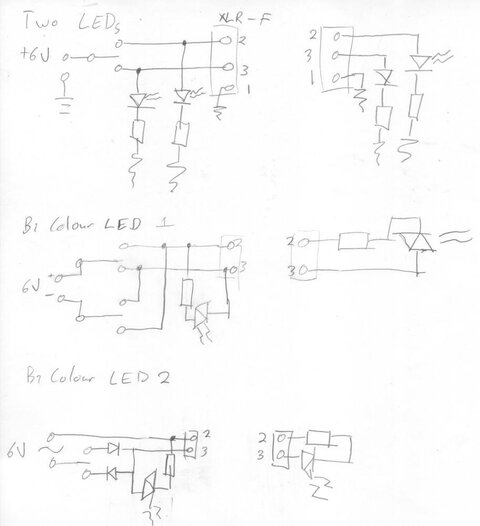

How would you go about setting up this system? What would you do differently than described? How would you wire in the LEDs, any resistors, or anything else relating to the project?

So today I was running XLR (20 minutes before the house opened!) with the ME for a newly home-brewed cue-light system. It was pretty interesting. A little DC power supply into a hobby box, with unknown electronics/wiring inside, two toggle switches and two XLR outs. The XLR was run from the hobby box to the cue-light location, and a small adapter was attached to the end of the run, also home-brew. He took a bare connector, and wired it up with the LED sticking out the hole where the cable would be...

Looked like a pretty nice little setup, and cheap/easy considering most theaters should have the parts on-hand.

How would you go about setting up this system? What would you do differently than described? How would you wire in the LEDs, any resistors, or anything else relating to the project?