What are everyones opinions on rigging lights using a base plate and 1.5" pipe vs drilling a floor flange directly into the deck and using that to hold up the pipe. Does the flange have enough support, is there a more affordable way to build base plates than dropping $200+ a piece to buy new ones?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Light Trees with Floor Flange vs Base Plate

- Thread starterHomeGrown

- Start date

Are you speaking of securing the base of a 1.5" schedule 40 boom supported by a hemp spot line or what manner of boom are you speaking of?What are everyones opinions on rigging lights using a base plate and 1.5" pipe vs drilling a floor flange directly into the deck and using that to hold up the pipe. Does the flange have enough support, is there a more affordable way to build base plates than dropping $200+ a piece to buy new ones?

How high above the deck are you going?

How many fixtures are you hanging?

Are you using boom arms?

All on one side? Two sides? Two sides plus off the front?

More detailed info' please.

Toodleoo!

Ron Hebbard.

Are you speaking of securing the base of a 1.5" schedule 40 boom supported by a hemp spot line or what manner of boom are you speaking of?

How high above the deck are you going?

How many fixtures are you hanging?

Are you using boom arms?

All on one side? Two sides? Two sides plus off the front?

More detailed info' please.

Toodleoo!

Ron Hebbard.

10' to 12' (Haven't decided yet) from the deck with 4 par 64 flood fixtures off the front. 1.5" schedule 40 pipe.

Its being used as an upstage system of audience blinders. No boom arms.

BillConnerFASTC

Well-Known Member

I don't think I know what you're asking. Instead of 50 pound 24" boom base, you want to use a standard threaded pipe flange lagged to floor? What do you mean by base plate and by floor flange?

Sorry - different traditions and training sometimes leaves a language barrier.

Sorry - different traditions and training sometimes leaves a language barrier.

A Floor flange does NOT have "enough support" Unless the pipe is being suspended from above by a "boom tie-off" Even then I would be hesitant to use a standard floor flange and would prefer something with a much larger foot print.What are everyones opinions on rigging lights using a base plate and 1.5" pipe vs drilling a floor flange directly into the deck and using that to hold up the pipe. Does the flange have enough support, is there a more affordable way to build base plates than dropping $200+ a piece to buy new ones?

Sorry there is not a lot of getting around it. Physics and safety agree you need a footprint, period, even without using side arms your 'load' is sitting 16-24" of the center-line of the pipe. Any movement, bumping-into, tripping over of those booms can cause enough stress to pop a flange loose.

@HomeGrown Read and heed what other posters are telling you, then add what I'm writing into your mix.

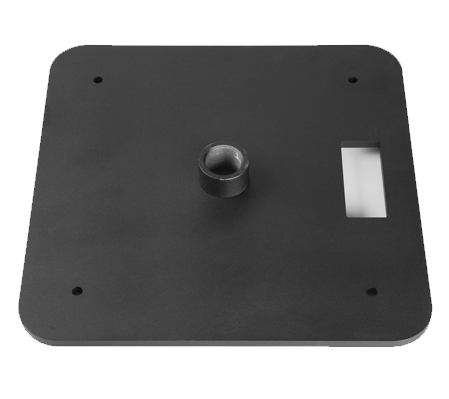

IF you're using a heavy duty, Kee Klamp brand, rated flange welded to a 24" square of 3/8" or 1/2" steel plate

IF your vertical pipe is 1.5" ID schedule 40 steel or aluminum pipe (Pipe NOT tube) and limited to 10'

IF you stack about 100 to 150 pounds of counter weights, sand bags, or water bags on the U/S side of the base plate

IF your PAR64 cans are short nose and aluminum

IF All of your cables are dressed tight to your vertical pipe such that all loads are directly down with no side loading and zero trip hazards

I MIGHT consider blessing this

NOTE: That's a whole lot of IF's and I'm not at all comfortable posting this from a distance and unseen.

Toodleoo!

Ron Hebbard.

Last edited:

soundlight

Well-Known Member

theatricalmatt

Well-Known Member

It's not just a question of "flange on the floor," but how the flange is attached. Drywall screws are notoriously brittle, and don't offer much strength; lag screws have much greater holding power, but put a larger (ie, permanent) hole into the stage floor. That might not be an issue if you're intending on building a permanent lighting position. If you have to go with a flange, you could either pick it to the grid, or use a sidearm or a cheeseboroughed pipe with a flange and attach it to a sturdy piece of scenery or wall.

I'll thirty-second the suggestion of just purchasing boom bases and pipe; renting's nice for short money but if you need them more than twice the shipping charges will eat up any savings you might garner. Another alternative might be tower truss, but your groundplan might argue against that.

I'll thirty-second the suggestion of just purchasing boom bases and pipe; renting's nice for short money but if you need them more than twice the shipping charges will eat up any savings you might garner. Another alternative might be tower truss, but your groundplan might argue against that.

RickR

Well-Known Member

DavidJones

Well-Known Member

I can see the argument for not wanting to have a base because of a trip hazard, but I feel like of you are close enough to trip on the base, you will probably run your head or knee into a fixture. Although a cast floor flange is more brittle than the pipe and more likely to crack, its the screws into the deck that will fail first. Even 24' square steel bases with pipe flanges bolted to them are a pretty good option, they have a reasonable footprint, good surface for sand bags and can stack for storage. Some may worry about the cast flange, but even with a lot of sandbags, you will tip a boom before that flange cracks, it may even break the threads off on the pipe before the flange fails. If you often use a lot of booms in the same places, I'm sure some sort of stage floor pocket exists for removable pipes, or could be made.

Whoo! You MUST be in the BIG LEAGUES! Where are you sourcing those 24 foot square steel bases you're posting of? Trucking them must come with its own problems.I can see the argument for not wanting to have a base because of a trip hazard, but I feel like of you are close enough to trip on the base, you will probably run your head or knee into a fixture. Although a cast floor flange is more brittle than the pipe and more likely to crack, its the screws into the deck that will fail first. Even 24' square steel bases with pipe flanges bolted to them are a pretty good option, they have a reasonable footprint, good surface for sand bags and can stack for storage. Some may worry about the cast flange, but even with a lot of sandbags, you will tip a boom before that flange cracks, it may even break the threads off on the pipe before the flange fails. If you often use a lot of booms in the same places, I'm sure some sort of stage floor pocket exists for removable pipes, or could be made.

Toodleoo!

Ron Hebbard.

JonathanHarpur

Member

We have some older floor plates here with flanges - they're heavy, solid 2-layers-of-1" ply bases, about 30" on a side, and the flanges are bolted on (there are 6" square plywood 'feet' [pads?] on each corner underneath to allow for the bolts and washers needed for this). We pile stageweights on these when they're in place, and don't go above 10', or three fixtures (standard Source IV ERS). Any more than that and we use steel floor plates instead, and even then, if it's more than 4 fixtures, we use truss, not pipe.

It sounds like, if budget's a concern, these wooden base plates might be an option in your space too.

Also, regardless of what we've placed, if we think they move too much when tested, we put safety lines from the grid onto them as well.

It sounds like, if budget's a concern, these wooden base plates might be an option in your space too.

Also, regardless of what we've placed, if we think they move too much when tested, we put safety lines from the grid onto them as well.

Something I haven't seen mentioned as a factor is the deck material the flange is screwing/lagging into. It may very well be only 3/4" T&G pine. Not very resistant at all to pull-out.

I'd advise never using a floor flange without top support. Bolting a flange to 30"x30"x2" of plywood sounds stable, but I'd still worry about weakness of the threads. In most flanges, there's only about 1/4"-3/8" of thread length making contact.

As far as boom base s, I think I like these, even though I've never used them.

http://www.ssrconline.com/pipes.html

A while ago, we discussed a rumor that Altman had discontinued its 50-pound boom base, but it still seems to be available, and $135 seems reasonable, considering that it will last virtually forever. Hopefully one only has to pay for shipping once.

http://www.productionadvantageonline.com/Products/B-50.aspx

-----

Finally, I'd be remiss if I didn't repeat a famous lighting designer's quote,

"They're BOOMS, not TREES, dang it. Dogs p!ss on trees!"

Yes, this is the same designer who used to say,

"It's a LAMP, dagnabit. A BULB is for planting in the ground to grow daffodils and tulips."

I'd advise never using a floor flange without top support. Bolting a flange to 30"x30"x2" of plywood sounds stable, but I'd still worry about weakness of the threads. In most flanges, there's only about 1/4"-3/8" of thread length making contact.

As far as boom base s, I think I like these, even though I've never used them.

http://www.ssrconline.com/pipes.html

A while ago, we discussed a rumor that Altman had discontinued its 50-pound boom base, but it still seems to be available, and $135 seems reasonable, considering that it will last virtually forever. Hopefully one only has to pay for shipping once.

http://www.productionadvantageonline.com/Products/B-50.aspx

-----

Finally, I'd be remiss if I didn't repeat a famous lighting designer's quote,

"They're BOOMS, not TREES, dang it. Dogs p!ss on trees!"

Yes, this is the same designer who used to say,

"It's a LAMP, dagnabit. A BULB is for planting in the ground to grow daffodils and tulips."

Something I haven't seen mentioned as a factor is the deck material the flange is screwing/lagging into. It may very well be only 3/4" T&G pine. Not very resistant at all to pull-out.

I'd advise never using a floor flange without top support. Bolting a flange to 30"x30"x2" of plywood sounds stable, but I'd still worry about weakness of the threads. In most flanges, there's only about 1/4"-3/8" of thread length making contact.

@derekleffew Your concern over the short length of threads, coupled with my concern over fracturing the threaded portion from the unthreaded portion of the schedule 40 pipe is why I've preferred using Kee Klamp (Brand) heavy duty, rated, slip-in / cup-point Allen head secured flanges over the more commonly employed threaded flanges.Something I haven't seen mentioned as a factor is the deck material the flange is screwing/lagging into. It may very well be only 3/4" T&G pine. Not very resistant at all to pull-out.

I'd advise never using a floor flange without top support. Bolting a flange to 30"x30"x2" of plywood sounds stable, but I'd still worry about weakness of the threads. In most flanges, there's only about 1/4"-3/8" of thread length making contact.

Toodleoo!

Ron Hebbard

DavidJones

Well-Known Member

Similar threads

- Replies

- 4

- Views

- 2K

- Replies

- 0

- Views

- 586

- Replies

- 0

- Views

- 846

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)