Sometimes for very long-term storage or transport without proper transit/

vehicle provisions, I'll slide a piece of cardboard in to the

gel frame of an

ellipsoidal or

fresnel. Good for when you have to

lay a

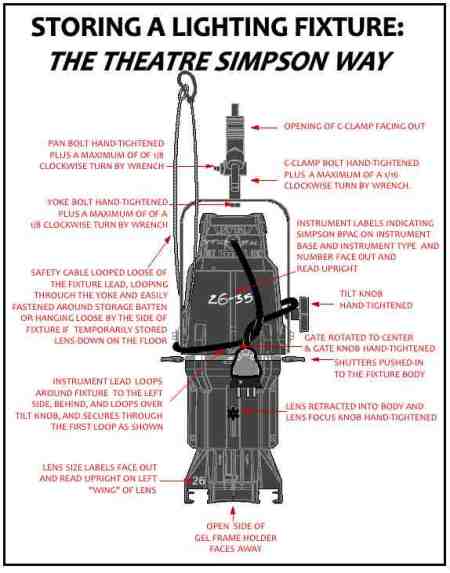

fixture on its side in the trunk of a car. I also secure whips and push in shutters, but I don't think I've ever gone through the lengths shown in the graphic Derek posted. Then again, most spaces I work in barely have enough fixtures to keep their rep circuits warm let alone have things go unused.

I've never known fixtures to gather more dust on the floor than they do when in the air. Main problem on the floor is that people tend to kick things over in the dark, and it isn't exactly the best use of vertical storage space.

Cardboard at least up North often retains moisture - though not a bad idea with synthetic material for dust to make it a little less, 1/2" thick miteral like hard foam would possibly be better. Lots of fixtures I have worked on over the years have suffered from sitting on the

gel frame clips to the concreat. Not a huge problem and the most often area to scratch up and easiest to fix. But a problem becomes when

gel frame brackets get bent or rusted inside the

concave. Bent can be fixed but causes problems with the weld or

rivet when done. Not a question of dust, it's the moisture that starts at what is touching cement even if not flooded.

But agreed rare a long term storage say unless summer

stock lights that are stored all winter say in the North. Here might be a question, if for long term storage spray everything down with oil and clean later or not? Perhaps better full service

call with oil to all fasteners and re-surfacing and coating before so when gear is again used, only a wipe down; or perhaps bagging the light, and putting a

sponge coated with oil inside the bag. With lots more options - if gear isn't going to be used for a while, I would think it better to service

call the gear before storage with light work after bringing it back, than directly sending used gear into storage without that service

call.

New gear can be stored for years, and I think most are bagged and come with oil packets or silica packets, old gear just put away often needs a lot of work to use. Serviced gear should I think if bagged and oil packet or silica packet (think that's what it is to absorb), allows for gear ready to go.