Hi there! I'm designing a set where I'd like certain walls to pivot and I could use some advise.

The idea is to have four walls making a cross, with the downstage 2 turning about 180 degrees each, and the upstage two stationary and braced/bolted into the stage behind.

My thought of how to do this was to double-hinge them and imbed a castor inside the far corner of the wall, so that performers can push it and it will pivot.

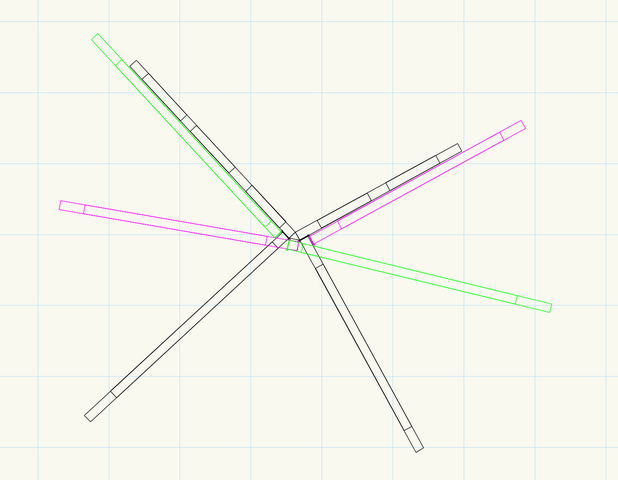

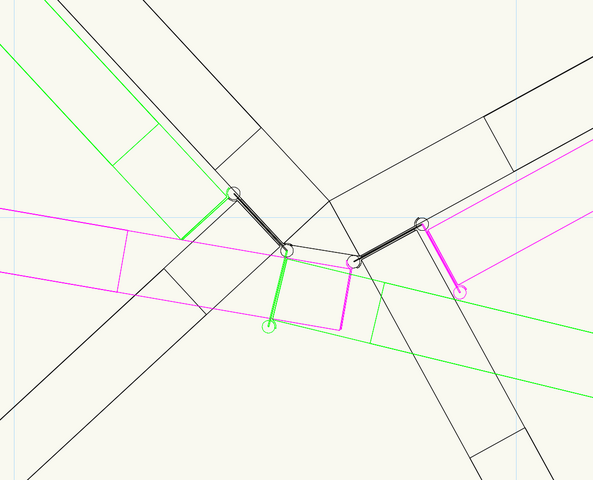

I've attached an image and close up of the hinge action. The two walls in black at the top of the image are stationary, the lower two are the mobile ones. The green wall outlines are most extreme pivot positions of the lower left wall, and the pink lines are the same for the lower right wall.

I think this all works on paper, however the walls are to be 2.8m H x 2.4-2.8m W, and I'm imagining about 125-200mm thick, and I'm worried it may not be possible to get hinges large or strong enough to work with that size and weight.

What do you think? Does this method make sense, or will it be too unstable? Or is there another, much better way to do this (bonus if it's one where the turning mechanism is not as obvious as a double hinge!)?

Thanks in advance!

The idea is to have four walls making a cross, with the downstage 2 turning about 180 degrees each, and the upstage two stationary and braced/bolted into the stage behind.

My thought of how to do this was to double-hinge them and imbed a castor inside the far corner of the wall, so that performers can push it and it will pivot.

I've attached an image and close up of the hinge action. The two walls in black at the top of the image are stationary, the lower two are the mobile ones. The green wall outlines are most extreme pivot positions of the lower left wall, and the pink lines are the same for the lower right wall.

I think this all works on paper, however the walls are to be 2.8m H x 2.4-2.8m W, and I'm imagining about 125-200mm thick, and I'm worried it may not be possible to get hinges large or strong enough to work with that size and weight.

What do you think? Does this method make sense, or will it be too unstable? Or is there another, much better way to do this (bonus if it's one where the turning mechanism is not as obvious as a double hinge!)?

Thanks in advance!