I've had several people ask me how to build a good quiet platform in the past. I just finished putting one together and built some new pieces. As long as I was doing it I thought I would take a bunch of pictures and post them. So what follows is a step by step guide through the system I use. I'm sure there are lots of other great options out there, but currently this is my favorite. I admit the platforms are very heavy... but they are very strong, very quiet, and very stable. I see no reason you couldn't use this system to build a platform 10 feet tall if you wanted.

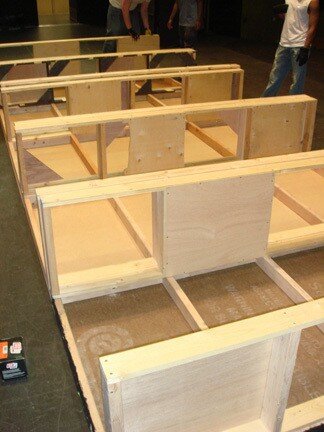

For the platform itself I use a 2X4 frame with a brace every 24 inches. The platform pictured is only a 48 inch square but you will see examples of an 8 footer below.

I place a layer of 1/2 inch sound proofing board underneath a layer of 3/4 inch plywood. This is the same fibrous stuff used in walls to keep the noise down between you and your neighbor. It's really nasty stuff to work with so use a respirator if you have to cut it. And be careful how you breathe when you are loading it at the lumber yard.

Think of your platform as a giant drum head. Keeping the platform quiet is all about minimizing vibration. So we use a thick plywood stock, we put a layer of sound deadener in the middle to absorb vibration, and by placing braces every 24 inches which are screwed into from the top we shrink down the area that is free to vibrate.

Now for the legs. Build legs of 1X4 and 2X4 as pictured below. The 2X4's are 24 inches apart... this lines up perfectly with the bracing on the platform to transfer the weight perfectly.

Now cut a cover for every second section. This is to create cross bracing to prevent rocking the long way on the platform down the road. I use 1/4 inch luan. You could also use 1/8 inch luan, or even Masonite. It doesn't have to be thick at all. It's simply fixing the distance on the surrounding 2X4's so they can't rock.

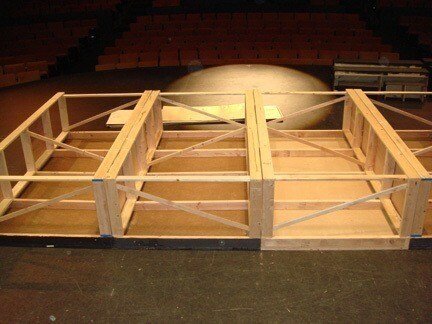

Now bolt together however many platforms you need.

And attach the leg units, 2 per platform. I just use either a 2 or 2 1/2 inch screw through the 1x4 of the leg unit and into the main long 2X4 of the platform. One screw per "square" is enough.

Now attach cross bracing to the legs. Each end gets a straight piece of 1X3 that matches the distance between the legs where they attach to the platform... make sure you've got everything square and plum in this step. Then add diagonal cross bracing every 4 feet. This doesn't have to be particularly strong... I use 1X2 or 1X3. Be sure that your diagonal cross bracing alternates for added strength... always pre-drill your holes when using 1X2 and 1X3, it WILL split.

If you are putting several platforms together be sure all your cross bracing is always high to low, low to high, in every direction there is never two of the same side by side...

That's it, now get an army and roll that bad boy over.

The only problem I have with this system is the occasional squeak of two platforms flexing when an actor walks. Often this can be solved by adding another bolt between platforms or tightening existing bolts. I'm thinking about adding some sort of thin rubber strip between platforms to prevent squeaks. To finish it off I just enclose it with luan facing.

Like I said, it's a serious pain in the butt to move around but it's quiet and strong. I've seen people stuffing platforms with pillows, blankets, even stapling fiberglass insulation underneath. You won't have to do that with this system. If you have the storage space, you can keep all the parts and re-assembly is very rapid. At my old high school over a period of several years I developed a nice stock of several standard heights. I could grab some 16, 24, or 32 inch legs and slap together the perfect platform in no time.

For the platform itself I use a 2X4 frame with a brace every 24 inches. The platform pictured is only a 48 inch square but you will see examples of an 8 footer below.

I place a layer of 1/2 inch sound proofing board underneath a layer of 3/4 inch plywood. This is the same fibrous stuff used in walls to keep the noise down between you and your neighbor. It's really nasty stuff to work with so use a respirator if you have to cut it. And be careful how you breathe when you are loading it at the lumber yard.

Think of your platform as a giant drum head. Keeping the platform quiet is all about minimizing vibration. So we use a thick plywood stock, we put a layer of sound deadener in the middle to absorb vibration, and by placing braces every 24 inches which are screwed into from the top we shrink down the area that is free to vibrate.

Now for the legs. Build legs of 1X4 and 2X4 as pictured below. The 2X4's are 24 inches apart... this lines up perfectly with the bracing on the platform to transfer the weight perfectly.

Now cut a cover for every second section. This is to create cross bracing to prevent rocking the long way on the platform down the road. I use 1/4 inch luan. You could also use 1/8 inch luan, or even Masonite. It doesn't have to be thick at all. It's simply fixing the distance on the surrounding 2X4's so they can't rock.

Now bolt together however many platforms you need.

And attach the leg units, 2 per platform. I just use either a 2 or 2 1/2 inch screw through the 1x4 of the leg unit and into the main long 2X4 of the platform. One screw per "square" is enough.

Now attach cross bracing to the legs. Each end gets a straight piece of 1X3 that matches the distance between the legs where they attach to the platform... make sure you've got everything square and plum in this step. Then add diagonal cross bracing every 4 feet. This doesn't have to be particularly strong... I use 1X2 or 1X3. Be sure that your diagonal cross bracing alternates for added strength... always pre-drill your holes when using 1X2 and 1X3, it WILL split.

If you are putting several platforms together be sure all your cross bracing is always high to low, low to high, in every direction there is never two of the same side by side...

That's it, now get an army and roll that bad boy over.

The only problem I have with this system is the occasional squeak of two platforms flexing when an actor walks. Often this can be solved by adding another bolt between platforms or tightening existing bolts. I'm thinking about adding some sort of thin rubber strip between platforms to prevent squeaks. To finish it off I just enclose it with luan facing.

Like I said, it's a serious pain in the butt to move around but it's quiet and strong. I've seen people stuffing platforms with pillows, blankets, even stapling fiberglass insulation underneath. You won't have to do that with this system. If you have the storage space, you can keep all the parts and re-assembly is very rapid. At my old high school over a period of several years I developed a nice stock of several standard heights. I could grab some 16, 24, or 32 inch legs and slap together the perfect platform in no time.

Last edited by a moderator: