Kolin Blakely

Member

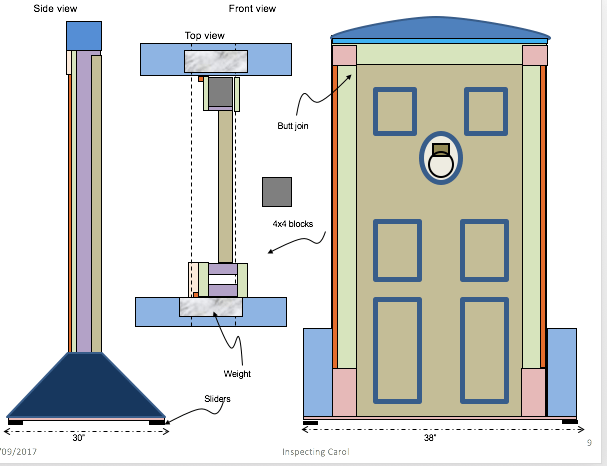

I've been challenged by the director to make "french doors" 12' wide 10' tall that need to be moved on and off stage... She wants it as close to the stage floor as possible so just placing on a rolling platform does not work. I'll attach a pic of my design... It'll be the top one in the pic... One issue is this is just 1x framing that the director wants to stay just the framing, no real support. My initial thought would be to get two small platforms on caster for the sides and then the door would "fall" in between the casters apprearing as though it's on the stage floor. The problem is there would be no rigidity and I'm afraid the framing would come apart from two separate platforms supporting each side. This probably makes no sense but any help would be appreciated. There won't be much weight to it since it's just 1x's but it's still pretty tall with no real structure.