You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Conventional Fixtures Pan Bolt Discussion

- Thread starterEsoteric

- Start date

Well then, you've always been wrong. (Must have gone to public school.)Derek I've always called them t clamps. ...

There's C-clamp, G-clamp, bar clamp, pipe clamp, Anderson clamp, Clancy clamp, gridlock clamp, hook clamp, Jorgensen clamp, trigger clamp, trim clamp, batten clamp, spring clamp, test clamp, amp clamp, hose clamp, and likely others; but no T clamp.

Re: New Lighting Blog Series: Types of Units

Wow what a strange thread.

Esoteric you are a cool guy and I generally agree with you. But, I'm completely stunned by your post. I've never met anyone who says don't use the pan bolt. In fact my experience has been exactly the oposite. I've known T.D.'s who would yell for days if they caught someone twisting on the fixture using the yoke bolt, because it's not safe. A properly tightened yoke bolt should be cranked down so tight that you can't move the fixture. If it's loose enough to move it's loose enough to potentially fail and fall. The pan bolt was designed for a job, use it correctly and it does that job well. I've been 4 years now in a brand new theater with all new gear. I've probably had 50 students hanging lights in that time. Some were great, some were terrible, but all were been properly trained. I haven't had a single broken pan nut or grooved spud shaft in that time. If you carry your wrench on some sort of proper lanyard, you can't leave it far away and you won't drop it so there's no reason that using it will slow you down. If c-clamp is so old the pan nut doesn't hold, it's time to buy a new c-clamp. I think we can all afford a $18 C-clamp every 30 years or so.

I respect you buddy, but have to completely disagree with you on this one.

Okay, I strongly discourage my techs from panning the unit with the set screw. It is too easy to break the head off, it is very easy to pull all the way out and strip it putting it back in, it is easy to create grooves in the shaft which effect focus, sometimes it takes too long to het a wrench on it when you can do a yoke bolt focus with just your hands, eventually the bolt will not tighten fully anymore. There is a laundry list of reason not use it for focus.

Wow what a strange thread.

Esoteric you are a cool guy and I generally agree with you. But, I'm completely stunned by your post. I've never met anyone who says don't use the pan bolt. In fact my experience has been exactly the oposite. I've known T.D.'s who would yell for days if they caught someone twisting on the fixture using the yoke bolt, because it's not safe. A properly tightened yoke bolt should be cranked down so tight that you can't move the fixture. If it's loose enough to move it's loose enough to potentially fail and fall. The pan bolt was designed for a job, use it correctly and it does that job well. I've been 4 years now in a brand new theater with all new gear. I've probably had 50 students hanging lights in that time. Some were great, some were terrible, but all were been properly trained. I haven't had a single broken pan nut or grooved spud shaft in that time. If you carry your wrench on some sort of proper lanyard, you can't leave it far away and you won't drop it so there's no reason that using it will slow you down. If c-clamp is so old the pan nut doesn't hold, it's time to buy a new c-clamp. I think we can all afford a $18 C-clamp every 30 years or so.

I respect you buddy, but have to completely disagree with you on this one.

Les

Well-Known Member

Re: New Lighting Blog Series: Types of Units

The main time I am guilty of panning with the yoke bolt is when a fixture is overhung, such as on a balcony rail. Otherwise, I really do try to use that pan bolt (not that it always happens). Do I believe yoke bolt panning is unsafe? Well, potentially, especially in the wrong hands (it takes about eight full turns to remove a yoke bolt). More so, it has the ability to put a lot of stress on the hanging bracket and the C-clamp, which may mar things up if care isn't taken.

The main time I am guilty of panning with the yoke bolt is when a fixture is overhung, such as on a balcony rail. Otherwise, I really do try to use that pan bolt (not that it always happens). Do I believe yoke bolt panning is unsafe? Well, potentially, especially in the wrong hands (it takes about eight full turns to remove a yoke bolt). More so, it has the ability to put a lot of stress on the hanging bracket and the C-clamp, which may mar things up if care isn't taken.

Last edited:

Re: New Lighting Blog Series: Types of Units

How do you rationalize that using the yoke bolt for pan on a Mega-clamp IS acceptable, but not on a "__me nut"-equipped clamp?

Is it the magic Belleville washer? (For the record, I think every yoke bolt should come with either a Belleville, or split lockwasher, but that's a (slightly) different discussion.)

There are many valid reasons for choosing to use one over the other, but I don't feel safety reasons are applicable criteria in either case. An electrician knowing when and where he/she has to apply a tool, and when not to, can make or break a focus session. It's easy and immediately apparent, to distinguish the beginners from the veterans.

So the minimum 1" long 1/2-13 yoke bolt that's 13 TPI is unsafe? During focus, rotating the yoke a max. of 45° L/R of center (1/8 of a revolution) will somehow cause the bolt to completely unscrew (min. 13 revolutions) and crash to the floor, causing immediate and painful injury/death to all occupants of the venue?

How do you rationalize that using the yoke bolt for pan on a Mega-clamp IS acceptable, but not on a "__me nut"-equipped clamp?

Is it the magic Belleville washer? (For the record, I think every yoke bolt should come with either a Belleville, or split lockwasher, but that's a (slightly) different discussion.)

There are many valid reasons for choosing to use one over the other, but I don't feel safety reasons are applicable criteria in either case. An electrician knowing when and where he/she has to apply a tool, and when not to, can make or break a focus session. It's easy and immediately apparent, to distinguish the beginners from the veterans.

Last edited:

Re: New Lighting Blog Series: Types of Units

My T.D. in college and mentor... who yelled a lot but not at me ... taught me that the yoke bolt was designed to be tight. If it was meant to be loose it would have a different design. What exactly? He didn't know because the Mega-clamp didn't exist. The Mega-clamp is designed to work differently. It is safe because it was designed to work that way. True there is a big difference between just slightly loose yoke bolt and yoke bolt so loose the instrument falls and kills all occupants of the venue. However the way some theaters (especially schools) are maintained and operated, I can easily see a scenario where a fixture just gets tugged and tweaked for years and years. Gradually, that yoke bolt could work it's way loose and the fixture (which also probably doesn't have a safety cable in this school theater of doom) falls.

... taught me that the yoke bolt was designed to be tight. If it was meant to be loose it would have a different design. What exactly? He didn't know because the Mega-clamp didn't exist. The Mega-clamp is designed to work differently. It is safe because it was designed to work that way. True there is a big difference between just slightly loose yoke bolt and yoke bolt so loose the instrument falls and kills all occupants of the venue. However the way some theaters (especially schools) are maintained and operated, I can easily see a scenario where a fixture just gets tugged and tweaked for years and years. Gradually, that yoke bolt could work it's way loose and the fixture (which also probably doesn't have a safety cable in this school theater of doom) falls.

In my book the proper use of yokes and c-clamps is a branch of rigging. Anytime you are rigging you always carefully choose the right tool for the right job because when you cut corners, eventually something bad happens. If using the c-clamp the way it's designed to be used causes you to break off an "f-nut" or groove a spud beyond useable once in a while, that is just the cost of safely doing business.

So the minimum 1" long 1/2-13 yoke bolt that's 13 TPI is unsafe? During focus, rotating the yoke a max. of 45° L/R of center (1/8 of a revolution) will somehow cause the bolt to completely unscrew (min. 13 revolutions) and crash to the floor, causing immediately and painful injury/death to all occupants of the venue?

How do you rationalize that using the yoke bolt for pan on a Mega-clamp IS acceptable, but not on a "__me nut"-equipped clamp?

There are many valid reasons for choosing to use one over the other, but I don't feel safety reasons are applicable in either case.

My T.D. in college and mentor... who yelled a lot but not at me

In my book the proper use of yokes and c-clamps is a branch of rigging. Anytime you are rigging you always carefully choose the right tool for the right job because when you cut corners, eventually something bad happens. If using the c-clamp the way it's designed to be used causes you to break off an "f-nut" or groove a spud beyond useable once in a while, that is just the cost of safely doing business.

Re: New Lighting Blog Series: Types of Units

So what is the appropriate torque setting for a yoke bolt?

I guess I just can't envision that scenario, as I assume any rational person (even middle school graduate chausman) has enough sense to tighten the yoke bolt with a wrench if the fixture is loose enough that it won't hold its focus.... I can easily see a scenario where a fixture just gets tugged and tweaked for years and years. Gradually, that yoke bolt could work it's way loose and the fixture (which also probably doesn't have a safety cable in this school theater of doom) falls. ...

So what is the appropriate torque setting for a yoke bolt?

Last edited:

STEVETERRY

Well-Known Member

Well then, you've always been wrong. (Must have gone to public school.)

There's C-clamp, G-clamp, bar clamp, pipe clamp, Anderson clamp, Clancy clamp, gridlock clamp, hook clamp, Jorgensen clamp, trigger clamp, trim clamp, batten clamp, spring clamp, test clamp, amp clamp, hose clamp, and likely others; but no T clamp.

Bravo!

ST

Les

Well-Known Member

Re: New Lighting Blog Series: Types of Units

I'm just going to bring this up in Esoteric's defense in that the pan bolt could have been stressed before he got to it. I'd imagine that years and years of various overzealous techs wrenching on that bolt, said hardware gets stressed and eventually fails. I once had the head of one literally fall off just by touching it with my wrench. Come to think of it, that may have given me a bad stigma about the things.

To give my 2 cents regarding how tight a yoke bolt is when I'm hanging the lights-- I usually like them tight enough that the fixture won't move if bumped, but not so tight that it can't be 'slightly adjusted' is the fixture is barely off its mark. The only time I really wrench them down is if the fixture is in an area where it is easily accessible (such as on a balcony rail AND/OR if the fixture has a very specific mark and needs to stay put).

First off I have never broken a pan bolt in my 11 years of focusing, if you break one your probably doing it wrong.

I'm just going to bring this up in Esoteric's defense in that the pan bolt could have been stressed before he got to it. I'd imagine that years and years of various overzealous techs wrenching on that bolt, said hardware gets stressed and eventually fails. I once had the head of one literally fall off just by touching it with my wrench. Come to think of it, that may have given me a bad stigma about the things.

To give my 2 cents regarding how tight a yoke bolt is when I'm hanging the lights-- I usually like them tight enough that the fixture won't move if bumped, but not so tight that it can't be 'slightly adjusted' is the fixture is barely off its mark. The only time I really wrench them down is if the fixture is in an area where it is easily accessible (such as on a balcony rail AND/OR if the fixture has a very specific mark and needs to stay put).

STEVETERRY

Well-Known Member

Re: New Lighting Blog Series: Types of Units

I am somewhat shocked not to have seen the most compelling reasons for not using the setscrew as a focusing tool, never mind breaking the bolt:

1. The cast surface of the c-clamp is irregular and rough.

2. There is considerable tolerance between the OD of the c-clamp shaft and the ID of the casting.

3. The result is completely unpredictable focus when rotating that shaft in that casting and then locking it with the setscrew.

4. I have $1000 in cash for the first person that can produce a professional stagehand who uses the setscrew at all.

5. We use the yoke bolt. Period.

ST

So the minimum 1" long 1/2-13 yoke bolt that's 13 TPI is unsafe? During focus, rotating the yoke a max. of 45° L/R of center (1/8 of a revolution) will somehow cause the bolt to completely unscrew (min. 13 revolutions) and crash to the floor, causing immediate and painful injury/death to all occupants of the venue?

How do you rationalize that using the yoke bolt for pan on a Mega-clamp IS acceptable, but not on a "__me nut"-equipped clamp?

Is it the magic Belleville washer? (For the record, I think every yoke bolt should come with either a Belleville, or split lockwasher, but that's a (slightly) different discussion.)

There are many valid reasons for choosing to use one over the other, but I don't feel safety reasons are applicable criteria in either case. An electrician knowing when and where he/she has to apply a tool, and when not to, can make or break a focus session. It's easy and immediately apparent, to distinguish the beginners from the veterans.

I am somewhat shocked not to have seen the most compelling reasons for not using the setscrew as a focusing tool, never mind breaking the bolt:

1. The cast surface of the c-clamp is irregular and rough.

2. There is considerable tolerance between the OD of the c-clamp shaft and the ID of the casting.

3. The result is completely unpredictable focus when rotating that shaft in that casting and then locking it with the setscrew.

4. I have $1000 in cash for the first person that can produce a professional stagehand who uses the setscrew at all.

5. We use the yoke bolt. Period.

ST

Re: New Lighting Blog Series: Types of Units

Sorry, you can only pull that scam once.

Is this the same $1000 that you owe to either sblair, pathway, or some yet-to-be-identified un-indicted co-conspirator?... 4. I have $1000 in cash for the first person that can produce a professional stagehand who uses the setscrew at all. ...

Sorry, you can only pull that scam once.

Last edited:

jstandfast

Active Member

Re: New Lighting Blog Series: Types of Units

Generally, if the c-clamp of the fixture I'm focusing has a nice, happy tension washer on the yoke bolt, I don't use the set screw. This has been pointed out before (in a thread about c-clamp maintenance I belive): mega clamps come default with a tension washer. So you can nudge the fixture in the right direction and it usually holds; if it doesn't hold, a slight tighten of the yoke bolt does the trick without screwing up your nice, new focus too bad.

Now if there's not a tension washer, or - god forbid - no washer at all, then the yoke bolt is so loose and stupid and finicky that all I want to do is crank it down hard and hope it stays that way. So then I default to the set screw/f-it nut/whatever. Needless to say I try to get tension washers on everything I can in my particular venue.

Side note: I cringe every time I have to tighten the t-handles on an instrument without these magical washers...usually these instruments are 360(Q)'s featuring a nice broken set of locking dogs.

Generally, if the c-clamp of the fixture I'm focusing has a nice, happy tension washer on the yoke bolt, I don't use the set screw. This has been pointed out before (in a thread about c-clamp maintenance I belive): mega clamps come default with a tension washer. So you can nudge the fixture in the right direction and it usually holds; if it doesn't hold, a slight tighten of the yoke bolt does the trick without screwing up your nice, new focus too bad.

Now if there's not a tension washer, or - god forbid - no washer at all, then the yoke bolt is so loose and stupid and finicky that all I want to do is crank it down hard and hope it stays that way. So then I default to the set screw/f-it nut/whatever. Needless to say I try to get tension washers on everything I can in my particular venue.

Side note: I cringe every time I have to tighten the t-handles on an instrument without these magical washers...usually these instruments are 360(Q)'s featuring a nice broken set of locking dogs.

Re: New Lighting Blog Series: Types of Units

I've seen at least one other manufacturer of a similar item, [-]but can't think of it so don't know what they call them.[/-] The Light Source, of course, and its Mega-Baby Sidearm MDBL Sidearm Slider, Black Anodized .

The Light Source, of course, and its Mega-Baby Sidearm MDBL Sidearm Slider, Black Anodized .

And BTW, how does one pan a fixture when using an Altman sliding tee? How would your TD mentor have done it, Gafftaper? Gee, there's no pan bolt, and Gafftaper told me using the yoke bolt was unsafe, so I guess I have to rotate the entire sidearm on the vertical pipe to pan the instrument. Oh yes, that's so much easier and safer! /sarcasm off

/sarcasm off

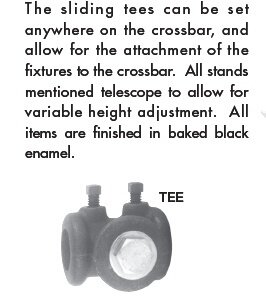

From the Altman document http://www.altmanlighting.com/altman-lighting-stage-hardware/stage-accessories.pdf :About this time last year I was building 100 sidearms. I'm fairly certain that both the vendor and the manufacturer refered to that hardware item in dispute as " Tee, Sidearm "

I've seen at least one other manufacturer of a similar item, [-]but can't think of it so don't know what they call them.[/-]

The Light Source, of course, and its Mega-Baby Sidearm MDBL Sidearm Slider, Black Anodized .

The Light Source, of course, and its Mega-Baby Sidearm MDBL Sidearm Slider, Black Anodized .

And BTW, how does one pan a fixture when using an Altman sliding tee? How would your TD mentor have done it, Gafftaper? Gee, there's no pan bolt, and Gafftaper told me using the yoke bolt was unsafe, so I guess I have to rotate the entire sidearm on the vertical pipe to pan the instrument. Oh yes, that's so much easier and safer!

Last edited:

techieman33

Well-Known Member

There are plenty of occasions where the only option is to use the clamp bolt to adjust the pan of an instrument, but if you have a PAN bolt then it should always be used first.

Frankly when I googled t clamp I came up with pictures of what we're talking about. So call me wrong all you want but honestly we all hear new terms everyday.Well then, you've always been wrong. (Must have gone to public school.)

There's C-clamp, G-clamp, bar clamp, pipe clamp, Anderson clamp, Clancy clamp, gridlock clamp, hook clamp, Jorgensen clamp, trigger clamp, trim clamp, batten clamp, spring clamp, test clamp, amp clamp, hose clamp, and likely others; but no T clamp.

jglodeklights

Well-Known Member

Re: New Lighting Blog Series: Types of Units

$18?!?!?!? You're paying too much! THIS BMI Supply carries Mega, Mega Pan, and standard C Clamps for $10-$11.

As for "T Clamp"....................

THIS is primarily what I get images or links for when I look up a T Clamp on google. Additionally, keep in mind that just because you find it on Google does not mean what you've found is correct, nor does it being local jargon make it correct.

Everyone I have worked with and everywhere I have worked have referred to them as sliding T's/Tees or simply T's/Tees.

$18?!?!?!? You're paying too much! THIS BMI Supply carries Mega, Mega Pan, and standard C Clamps for $10-$11.

As for "T Clamp"....................

THIS is primarily what I get images or links for when I look up a T Clamp on google. Additionally, keep in mind that just because you find it on Google does not mean what you've found is correct, nor does it being local jargon make it correct.

Everyone I have worked with and everywhere I have worked have referred to them as sliding T's/Tees or simply T's/Tees.

Re: New Lighting Blog Series: Types of Units

So am I right or wrong to consider safe C-clamp, yoke usage and safety cabling a fixture to be part of rigging? If I'm wrong why? Is it okay to use any product designed for overhead lifting in a way it was not designed to be used? I love arguing with Derek.

Yes you have to use the yoke bolt equivalent on a sliding Tee. BUT, you are using that product the way it was designed to be used. ...and I don't believe in rotating the sidearm I believe in rotating the entire vertical pipe.And BTW, how does one pan a fixture when using an Altman sliding tee? How would your TD mentor have done it, Gafftaper? Gee, there's no pan bolt, and Gafftaper told me using the yoke bolt was unsafe, so I guess I have to rotate the entire sidearm on the vertical pipe to pan the instrument. Oh yes, that's so much easier and safer!/sarcasm off

So am I right or wrong to consider safe C-clamp, yoke usage and safety cabling a fixture to be part of rigging? If I'm wrong why? Is it okay to use any product designed for overhead lifting in a way it was not designed to be used? I love arguing with Derek.

About $18 is the standard price for an ETC clamp online. Which is one of the higher priced C-clamps. Yes there are cheaper options many as low as $10. However, in order to make the point as fair as possible to the other side, I chose a higher end product at a non-package price.$18?!?!?!? You're paying too much! THIS BMI Supply carries Mega, Mega Pan, and standard C Clamps for $10-$11.

Similar threads

Vintage Lighting

1st Altman Shakespeare worked on

- Replies

- 7

- Views

- 3K

Conventional Fixtures

Lycian 1209 Midget HP Dual ended lamp version?

- Replies

- 9

- Views

- 3K

- Replies

- 28

- Views

- 6K

- Replies

- 0

- Views

- 731

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)