Here is what is wanted:

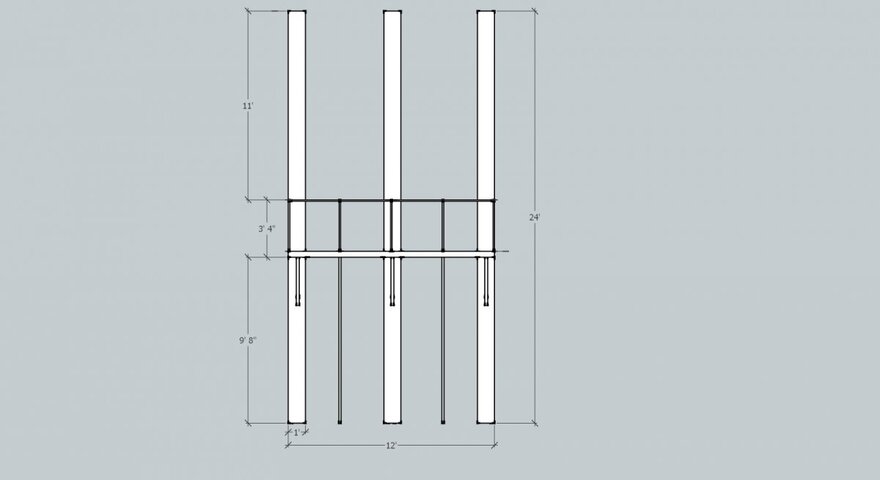

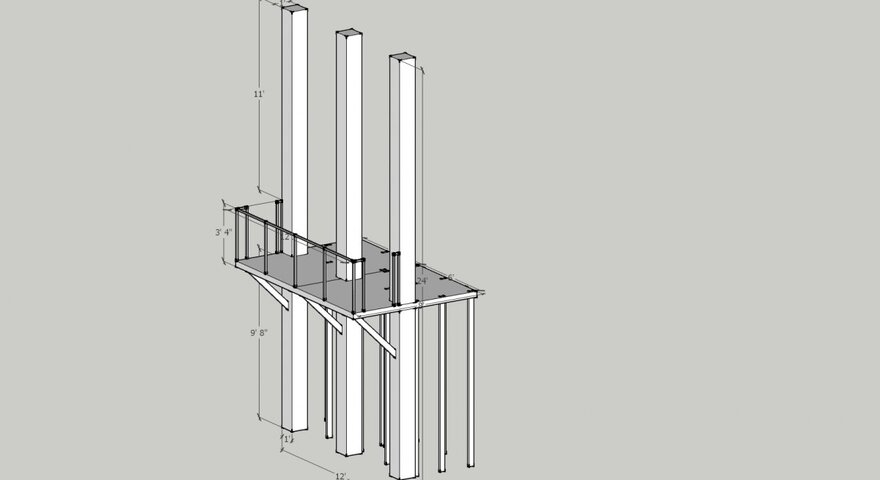

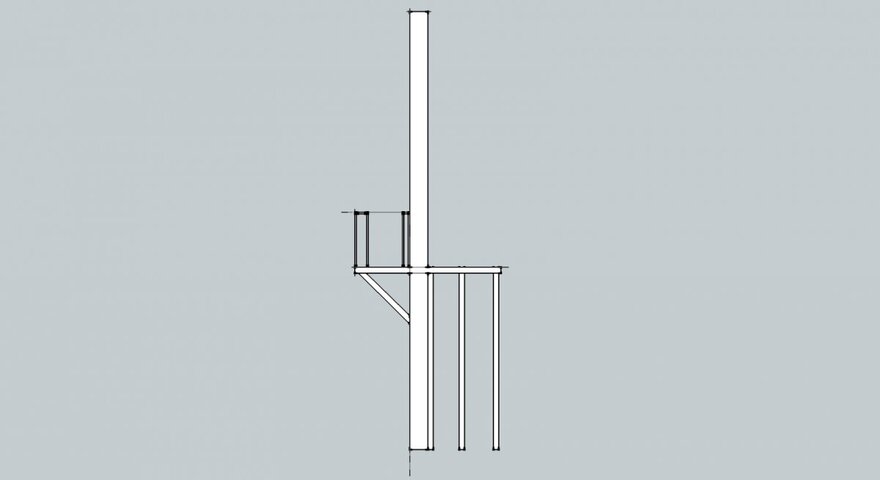

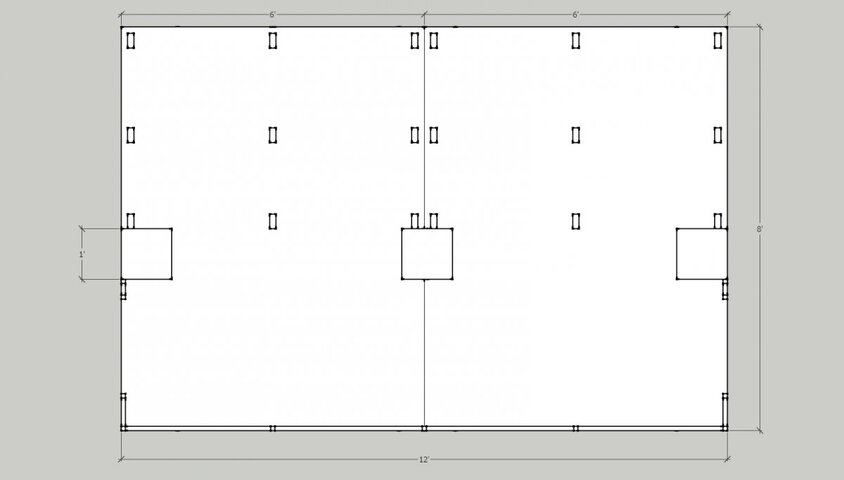

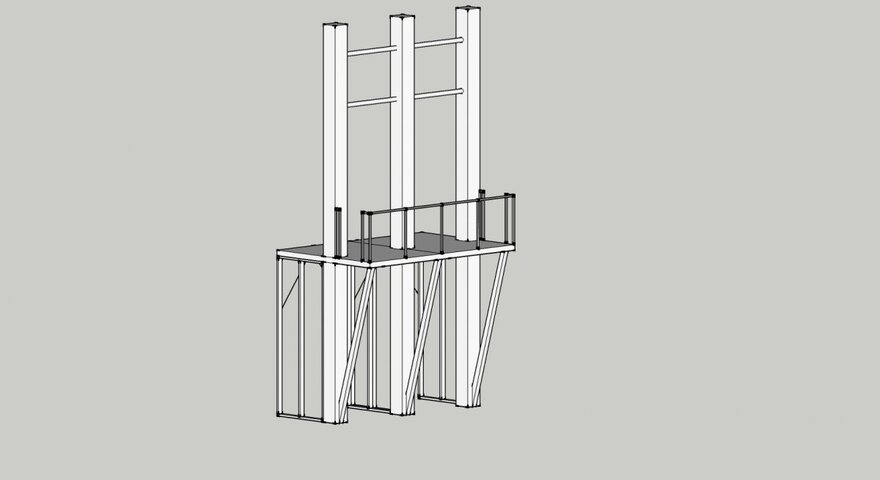

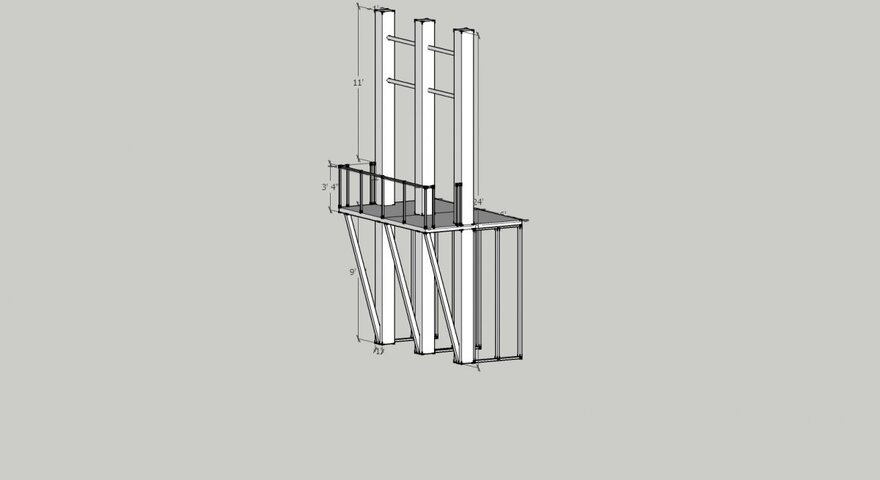

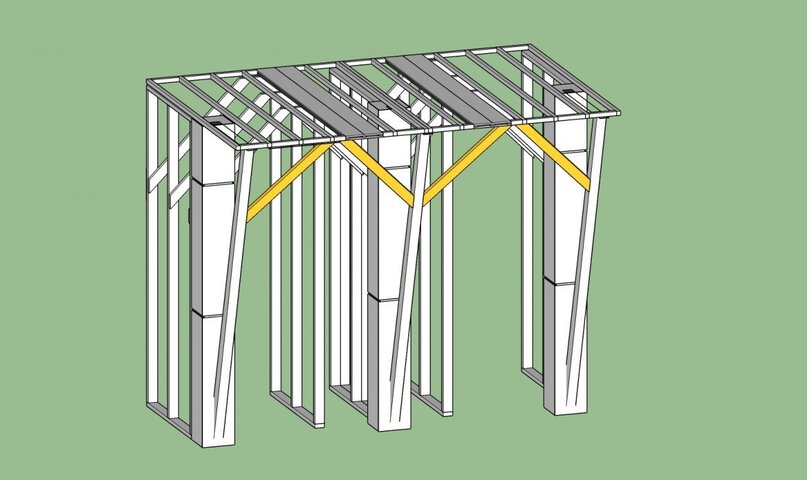

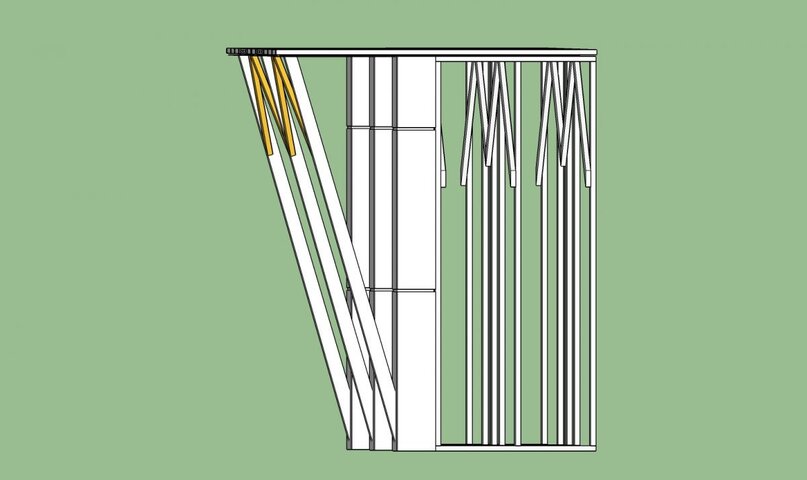

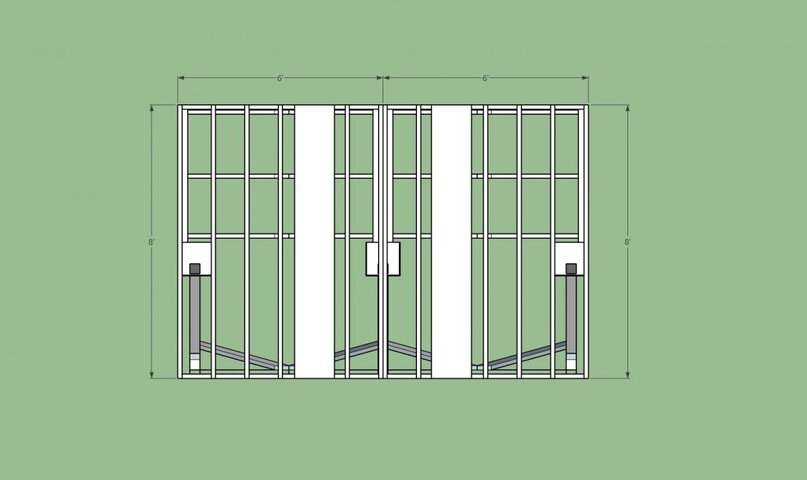

A 8' x 12' platform with a 3'x12' section cantilevered but supported with bracing to 3 posts at 10' roughly off the ground. Check out the images for a better look (It does not have cross bracing on legs). Due to load in doors, the structure would have to be (2) 6x8. Now I know that it appears sketchy and more of a design for a bookshelf, not something that will support actors. Has anyone had a similar scenario with a supported cantilever? Perhaps thoughts on faking the look? I'd love some ideas before I opening up the structural design book to do free body diagrams and calculations.

A 8' x 12' platform with a 3'x12' section cantilevered but supported with bracing to 3 posts at 10' roughly off the ground. Check out the images for a better look (It does not have cross bracing on legs). Due to load in doors, the structure would have to be (2) 6x8. Now I know that it appears sketchy and more of a design for a bookshelf, not something that will support actors. Has anyone had a similar scenario with a supported cantilever? Perhaps thoughts on faking the look? I'd love some ideas before I opening up the structural design book to do free body diagrams and calculations.