Scott Lumley

Active Member

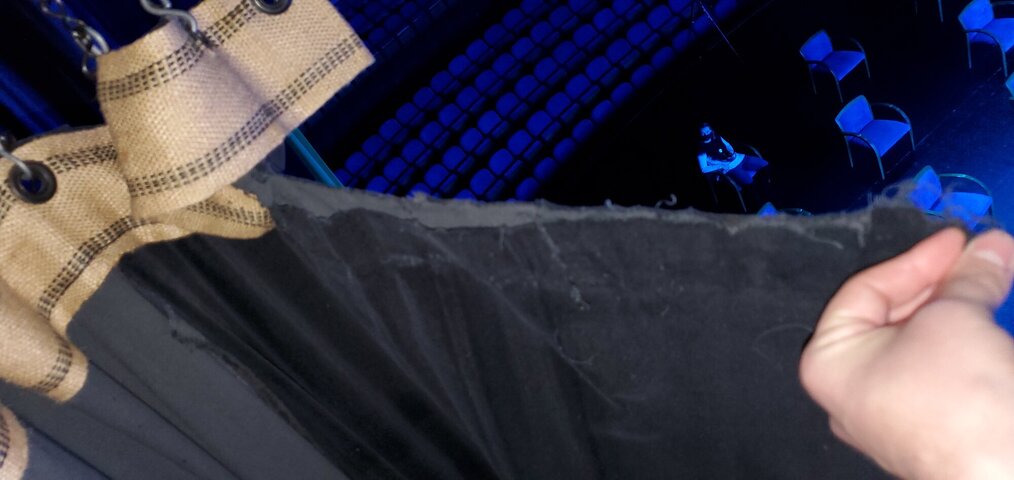

Hi everyone, I have a stage curtain that has torn at the top, by the grommets (pictures are attached). Does anyone have a suggestion on how I might temporarily repair the curtain until we can get a professional company out to fix it?

I don't know much about curtains and we can't afford to bring an expert in right now to repair it. They are going on 17 years old, and as far as I know, never had any maintenance or repairs. I don't have any information on them though, but have reached out to the original company that made them to see if they can send me any information on them. I know they are roughly about 20 feet tall.

A faculty member suggested we clamp the curtains with like a c-clamp for wood working. I didn't think that was a good idea because I don't feel like that would hold it together, and instead, it might fall on someone's head if they bumped into the curtain. Then they asked if there was a way for me to put like a safety cable on the c clamp to prevent that, but I don't know how I would really attach one that would for sure stay on since c-clamps weren't really designed for that. Also, if it fails (even if it doesn't hit someone in the head), it might create a shock load on the curtain from the curtain falling again that would tear it even more. I am just having a hard time thinking this might be a solution.

A staff member suggested that I sew it back together for now (even though I don't know anything about sewing). I don't think the normal thread and needles people have at their house would work for this though. The curtain is just too heavy and would rip the new threads apart I would think. Again, this would probably also create a shock load that would rip even more of the curtain if the stitching failed.

I thought about possibly getting some kind of jumbo safety pins maybe, but I worry pushing the pin through would make too big a hole and that it might actually end up tearing vertically up to the torn part of the curtain.

Any feedback or suggestions are appreciated. Thank you!

I don't know much about curtains and we can't afford to bring an expert in right now to repair it. They are going on 17 years old, and as far as I know, never had any maintenance or repairs. I don't have any information on them though, but have reached out to the original company that made them to see if they can send me any information on them. I know they are roughly about 20 feet tall.

A faculty member suggested we clamp the curtains with like a c-clamp for wood working. I didn't think that was a good idea because I don't feel like that would hold it together, and instead, it might fall on someone's head if they bumped into the curtain. Then they asked if there was a way for me to put like a safety cable on the c clamp to prevent that, but I don't know how I would really attach one that would for sure stay on since c-clamps weren't really designed for that. Also, if it fails (even if it doesn't hit someone in the head), it might create a shock load on the curtain from the curtain falling again that would tear it even more. I am just having a hard time thinking this might be a solution.

A staff member suggested that I sew it back together for now (even though I don't know anything about sewing). I don't think the normal thread and needles people have at their house would work for this though. The curtain is just too heavy and would rip the new threads apart I would think. Again, this would probably also create a shock load that would rip even more of the curtain if the stitching failed.

I thought about possibly getting some kind of jumbo safety pins maybe, but I worry pushing the pin through would make too big a hole and that it might actually end up tearing vertically up to the torn part of the curtain.

Any feedback or suggestions are appreciated. Thank you!