CSCTech

Active Member

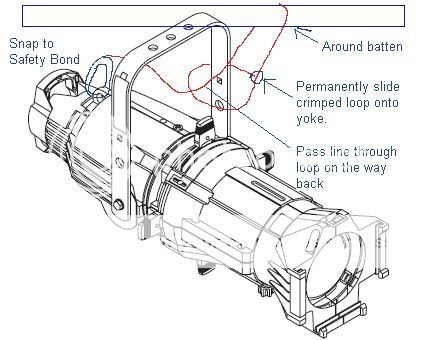

Somewhat off topic, but in regards to safety cable and not using spring loaded 'carabiner clip' type cables for over-head hanging. Is this what is meant?

If so what is the correct type to use on over-head fixtures? As we use one of those on all of our fixtures, they have been there since the original install so I have never second-guessed them. (Didn't even know there was a different kind of safety cable)

If so what is the correct type to use on over-head fixtures? As we use one of those on all of our fixtures, they have been there since the original install so I have never second-guessed them. (Didn't even know there was a different kind of safety cable)