randoturbo33

New Member

Hi guys,

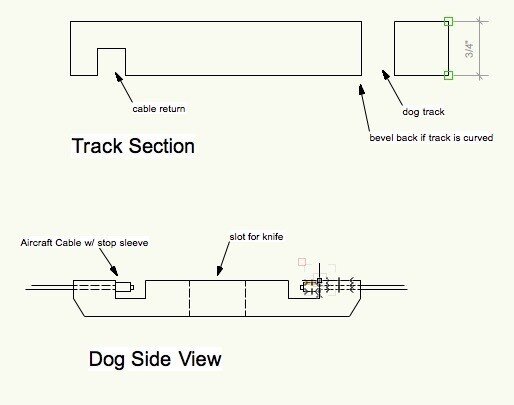

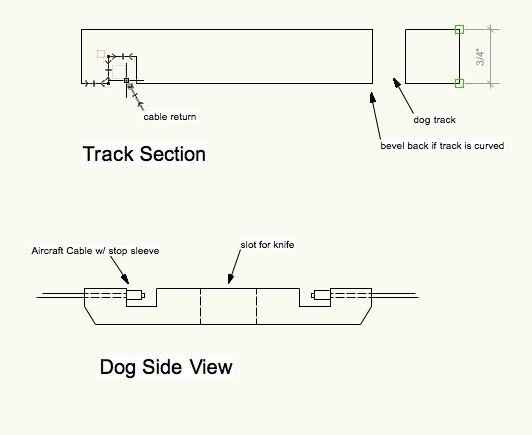

I've recently been tasked with building some track platforms for use with a dog-and-knife track system. There are 3 tracks in the show that run the full width of the stage. For various reasons, we want to avoid the typical approach of having the track be made from two separate platforms with a gap between them and just running the dog on the floor - rather, the track should be integrated into one platform and contain an internal "shelf" that the dog will run on. I have a large budget, highly skilled carpenters, and can use both wood and steel, whichever would be better. The deck needs to be 6" tall to the top of the lid.

I've never built something like this, so I'm looking for input and advice, and maybe even sample plans for how people have done it in the past. I believe that touring productions often use tracks like these, so some input from that world would be awesome as well. I've been playing with various ideas for a few days, but I'd really appreciate input from someone who's done this before in order to head off some of the numerous problems that I'm sure will arise.

Thanks!

I've recently been tasked with building some track platforms for use with a dog-and-knife track system. There are 3 tracks in the show that run the full width of the stage. For various reasons, we want to avoid the typical approach of having the track be made from two separate platforms with a gap between them and just running the dog on the floor - rather, the track should be integrated into one platform and contain an internal "shelf" that the dog will run on. I have a large budget, highly skilled carpenters, and can use both wood and steel, whichever would be better. The deck needs to be 6" tall to the top of the lid.

I've never built something like this, so I'm looking for input and advice, and maybe even sample plans for how people have done it in the past. I believe that touring productions often use tracks like these, so some input from that world would be awesome as well. I've been playing with various ideas for a few days, but I'd really appreciate input from someone who's done this before in order to head off some of the numerous problems that I'm sure will arise.

Thanks!