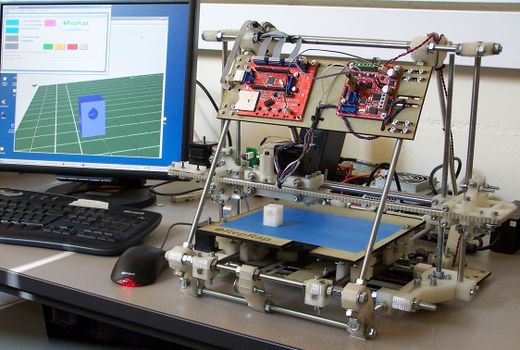

I've been sick and listening to lots of coverage of CES over the last week. Perhaps the coolest thing out I heard about is MakerBot It "Prints" 3 dimensional objects out of ABS plastic up to 4"x4"x6". Create a 3-D image in a computer and press print and less than 4 hours you'll have a plastic copy of it. You can have your own for a little over $1200 so it's actually affordable so with a little saving even a small shop could potentially afford one.

When people create a design they upload it to share in the "Thingverse". There are lot's of cool projects out there waiting for you to "print".

Upon further reading it looks like you can even import things to print out of the vast archives of the Google Sketchup 3D Warehouse AND out of Google Earth.

When people create a design they upload it to share in the "Thingverse". There are lot's of cool projects out there waiting for you to "print".

Upon further reading it looks like you can even import things to print out of the vast archives of the Google Sketchup 3D Warehouse AND out of Google Earth.

Last edited: