bobgaggle

Well-Known Member

I'm having a problem clearly notating cutlists with miters.

My usual notation:

4 @ 36" L-L 45-45 (this returns a trapezoid, 36" on the long side)

or

4 @ 36" L-S 45-45 (this returns a parallelogram, 36" from acute angle to obtuse angle)

or

4 @ 36" -L 45 (one end square, one end 45, 36" to the longest side)

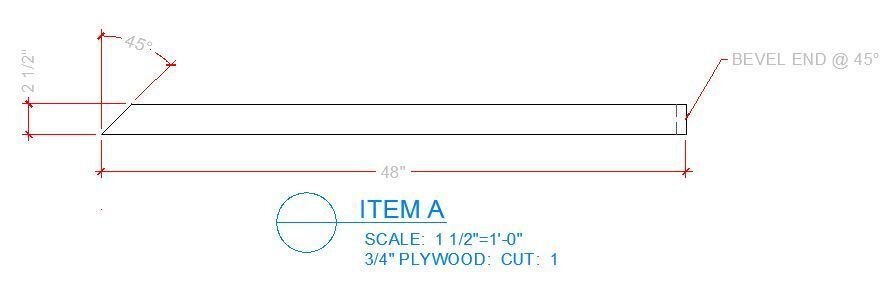

This is pretty standard in the shops I've worked in. My problem comes when I need to miter and bevel the same piece. Not a compound angle, one end mitered the other beveled. I don't know how to notate this. Is there a standard way this is usually done? Maybe 4 @ 36" M-B 45-45? But this doesn't really tell the guy where to measure from to get an accurate length...

My usual notation:

4 @ 36" L-L 45-45 (this returns a trapezoid, 36" on the long side)

or

4 @ 36" L-S 45-45 (this returns a parallelogram, 36" from acute angle to obtuse angle)

or

4 @ 36" -L 45 (one end square, one end 45, 36" to the longest side)

This is pretty standard in the shops I've worked in. My problem comes when I need to miter and bevel the same piece. Not a compound angle, one end mitered the other beveled. I don't know how to notate this. Is there a standard way this is usually done? Maybe 4 @ 36" M-B 45-45? But this doesn't really tell the guy where to measure from to get an accurate length...