an intersting turn of events

http://www.boston.com/news/local-ne...circus-act-sue-rhode-island-convention-center

http://www.boston.com/news/local-ne...circus-act-sue-rhode-island-convention-center

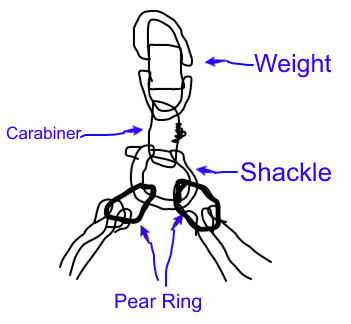

I believe, and correct me if I'm wrong, that OSHA is suggesting that the two pear rings should have been connected to a shackle which could then be attached to the carabiner, thus loading the carabiner along it's major axis. The report didn't appear to condemn the use of carabiners in the system though.

Tort law in this country is crazy, and how do they claim the biner was defective, and not just the wrong choice?

So @porkchop, @What Rigger? , and @egilson1 I have a question for my "Rafter American" friends. Instead of tri-axial loading a single carabineer, could you use two carabineers (coming in at the angles from the bottom) and connect them to a single larger shackle on top? This would put the triaxial load on the shackle while still allowing a relatively quick connection/disconnect time.

.So @porkchop, @What Rigger? , and @egilson1 I have a question for my "Rafter American" friends. Instead of tri-axial loading a single carabineer, could you use two carabineers (coming in at the angles from the bottom) and connect them to a single larger shackle on top? This would put the triaxial load on the shackle while still allowing a relatively quick connection/disconnect time.

View attachment 13507

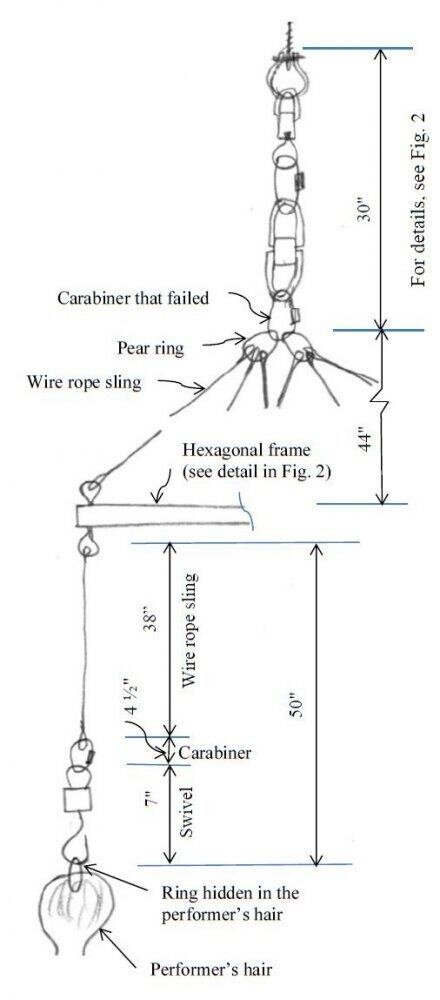

Just went back and checked the OSHA report (sketch and photo below from OSHA report). The failed Carabiner connected directly to a weight. So to correct my question and Bill's question @What Rigger? , @porkchop , and/or @egilson1, could they have gone from the two pear rings to two carabiners and then triaxially load the weight.. That is what I wondered. Wondered if the swivel ring could have been loaded triaxially.

That's my understanding of what they said would have been acceptable.In the spirit of terrible drawings I think this would be an acceptable configuration:

View attachment 13511

Just went back and checked the OSHA report (sketch and photo below from OSHA report). The failed Carabiner connected directly to a weight. So to correct my question and Bill's question @What Rigger? , @porkchop , and/or @egilson1, could they have gone from the two pear rings to two carabiners and then triaxially load the weight.

View attachment 13509

View attachment 13508

I recall a conversation I had with Jay Glerum where he told me that quick links should never be used in rigging because they are by design a broken circle with a built in fail point. It seems like you are making a similar objection to carabiners.

Yes, and no.

Your proposed solution would eliminate the issue of tri-axial loading of a carabiner, but does not address the issue of using a product not actually rated for lifting. My interpretation of the OSHA report is that item #4 of the conclusions indicates not using carabiners in the load path.

Earlier in this thread someone posted the link the the Protocol article Rocky did back in 2014 about why not to use climbing gear for entertainment rigging, and its a very good read. Karl Rulling, the Technical Standards manager for ESTA wrote a sidebar which reviewed an earlier article he wrote in 2003 called "You call that Strong" (I attached it here, but warn you its a very technical read). Karl's sidebar discusses the technical process of determining WLL for rigging hardware and how that differs from climbing hardware. The critical difference is the requirement to proof test industrial lifting equipment before its sold. Each and every item is proof tested. Climbing hardware is not.

It is possible that the failed carabiner from the Feld accident is one of the outliers (0.135% of carabiners produced) that was going to fail below the mean minimum breaking strength.

This was the basis of the discussion I ldid at LDI last year with Jeff Reder. Are you ok with risking a failure by using a product that 1 or 2 out of 1000 is weaker than the others?

Personally, I'm no willing to make that choice and for which reason I do not use carabiners for rigging. I pick hardware that follows written standards like ASME B30.26, and federal regulations like RR-C-271F. By doing so if/when i have a failure I've got the backing of those standards to help me in court, and not just some design factor that is kinda sorta generally accepted for me to use to calculate my own WLL from the MBS of the carabiner.

my personal solution to this particular challenge would be a shackle to something like a CM Latchlok hook. Locking, load rated, and fast.

Regards,

Ethan

Honest question not trying to be snarky, the latchlok hook is a good solution when you're using a chain hoist but what kind of quick connecting means would you suggest for a winch that uses SWR? Snap shackles don't seem superior to an ANSI Z359 stamped carabiner but shackles are way too slow for some effects (and having a loose pin over the audience, in the dark, 400+ shows a year is asking for trouble). I've seen some sliding latch hooks that I don't actually know the name of, but they are pretty light weight and don't seem like they'd be acceptable for lifting people.

Thanks @egilson1 @porkchop and @What Rigger? . To those of us who only know enough about rigging to be dangerous, this is a fascinating discussion. It's great having the opportunity to hear from people who do this for a living.

I recall a conversation I had with Jay Glerum where he told me that quick links should never be used in rigging because they are by design a broken circle with a built in fail point. It seems like you are making a similar objection to carabiners.

We use essential cookies to make this site work, and optional cookies to enhance your experience.