An interesting (to me, anyway) discussion arose at work yesterday. A rigger stated, "No truss manufacturer approves or advocates its truss for use in a diamond configuration." So should one...

Not an official poll, as I'm not looking to reach a consensus; just want discussion from experts.

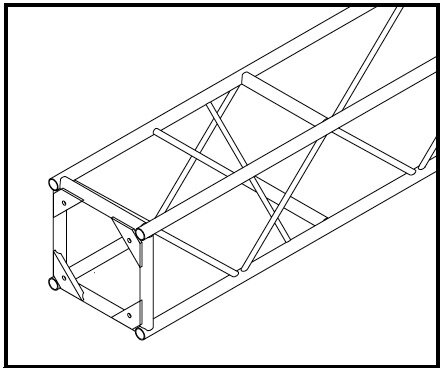

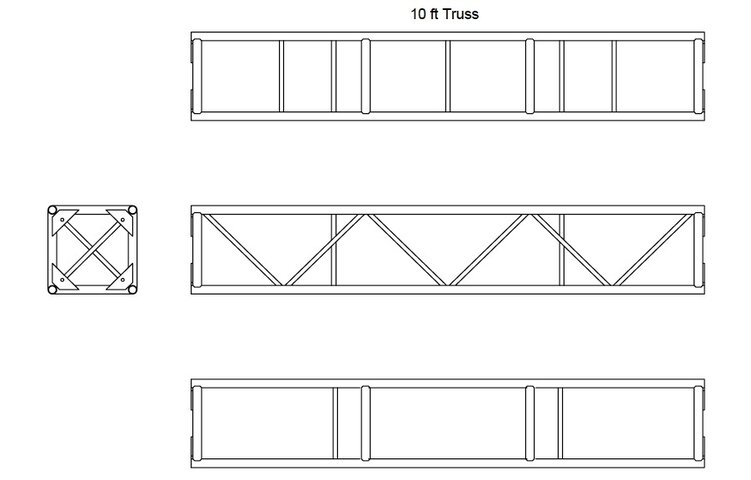

BTW, the truss in question was 20.5"x20.5", 70' long, picked with three 1T Lodestar s, and held 24x 80 lb. fixture s.

- Never do it. Period. End of story.

- Apply some sort of derating factor (either less load or more closely-spaced points).

- It's perfectly fine, whether or not the mfg approves it.

- Other (Please explain...).

Not an official poll, as I'm not looking to reach a consensus; just want discussion from experts.

BTW, the truss in question was 20.5"x20.5", 70' long, picked with three 1T Lodestar s, and held 24x 80 lb. fixture s.

Last edited: