JacobRothermel

Active Member

Any stick is better than no stick, without question. Pulling a work piece through might be fine in experienced hands (I've also used the trick of flipping the work piece over 180 and cutting the other end in some instances if no stick is handy...) but if you're teaching inexperienced folks (i.e., students, etc.) you need to keep things direct and simple. Keep your hands clear at ALL TIMES; that means use a push stick.

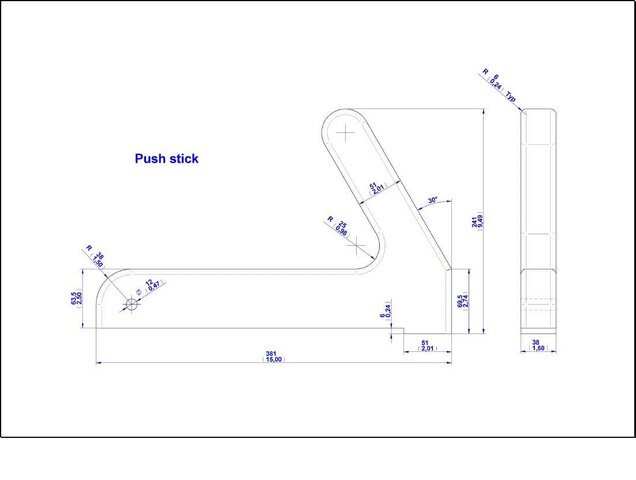

Once again, I find myself agreeing with Aaron up above about the middle of the three pictured being my favorite and, likely in my opinion, the 'safest' of the three. The bottom push stick, whilst certainly effective, has a higher learning curve in my experience. It also doesn't adequately keep the work piece from riding up the back of the saw blade as it's pushed through the saw because it only provides contact that the very end (front) of the piece.

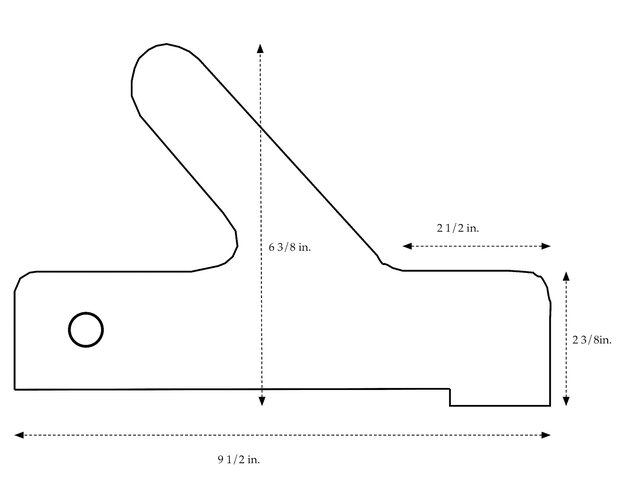

The top one doesn't have any kind of lip or toe to mechanically catch the edge of a work piece as it's being pushed through and I'd worry it might slip, even with some kind of friction material to help. That one is good for jointers or router tables.

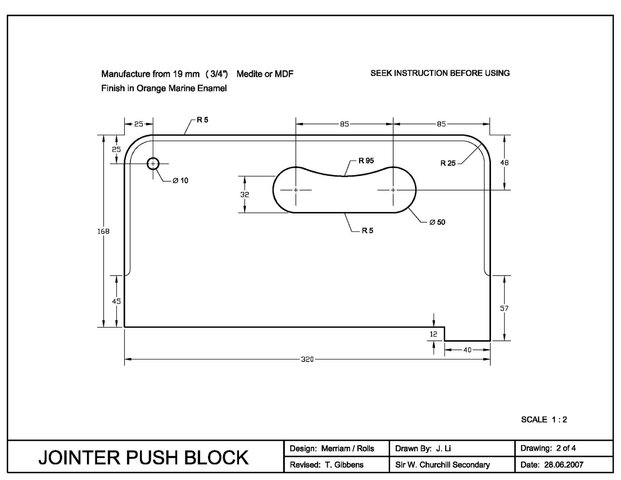

I like the middle version, or variants thereof (see attached), because it a] keeps your hands clear of the blade (obviously), b] provides downward force along more of the work piece, helping to ensure it stays flat on the table top as the cut is made, and c] they're easy to make and easily distinguished between a tool and a piece of scrap wood.

Plastic and metal versions are RIGHT. OUT. in my shop; no metal, espeically on my brand new SawStop, thank you very much....

Good luck,

Once again, I find myself agreeing with Aaron up above about the middle of the three pictured being my favorite and, likely in my opinion, the 'safest' of the three. The bottom push stick, whilst certainly effective, has a higher learning curve in my experience. It also doesn't adequately keep the work piece from riding up the back of the saw blade as it's pushed through the saw because it only provides contact that the very end (front) of the piece.

The top one doesn't have any kind of lip or toe to mechanically catch the edge of a work piece as it's being pushed through and I'd worry it might slip, even with some kind of friction material to help. That one is good for jointers or router tables.

I like the middle version, or variants thereof (see attached), because it a] keeps your hands clear of the blade (obviously), b] provides downward force along more of the work piece, helping to ensure it stays flat on the table top as the cut is made, and c] they're easy to make and easily distinguished between a tool and a piece of scrap wood.

Plastic and metal versions are RIGHT. OUT. in my shop; no metal, espeically on my brand new SawStop, thank you very much....

Good luck,