Whoa, You really only get 3-4 lamp cycles before needing to replace a

socket? My VL3000s have gotten through at least 8-10, and haven't replaced any as far as I can remember.

And some of those fixtures were purchased used.

That being said, I understand I am getting close to end of life on those sockets, And in my experience, and what I have been told is that

Mac 2k burns through sockets much faster than VL3000. But it gets better if you replace both lamp fans at the same time as the

socket.

(Forgive my above misspellings

etc. in above post. Was a really quick post to get it out after a few errors in trying.) Note also, if creating a who owns the lamp sticker to put on the lamp for lamp changes and possibly warranty purposes...

Date, Who changed it,

Fixture serial number, Reason for replacement, Lamp hours, Lamp strikes, and Lamp

socket changed? In addition to

logo of who owns the lamp and phone number. Also the serial number of what's in the box as at times mistakes happen and or if inspecting a hundred lamps in a day... gets painful to look for serial numbers on them as opposed to doing it if possible on-site with only a few changed. Such stickers help a lot in

tracking lamps, ensuring the get back to you if mis-placed, and if a good sticker one can see it has been removed in not buying if seen on E-Bay. If a warranty claim, this info will be important as with also computer

tracking the history of the lamp - when bought, from who and what

Purchase order. Also when you get a new lamp, write it's serial number and lot number on the box so you know what lamp was installed into the

fixture. Also helps in

tracking what lamp is where or not returned after a show.

Tracking lamp serial numbers is really useful. Say a truck gets into a crash, or shipping container with a show falls overboard. Or right out of the shop the video

projector part of a DL-2 gets stolen... able to provide in addition to

fixture serial number, the lamp serial number to the police also as with it's value. Lamp serial numbers have to be unique though.... Osram once in a while has had duplicates on the same lamp but normally is good for being unique. Philips and GE when given are often multitudes of serial numbers that are the same... no idea of why. That's why if possible take out a graphite pencil for a

porcelain base and make your own serial number.

Laser etched glass look for though, than write it with graphite also on the

base in assuming an outer pinch failure for a single ended lamp and it gone. Otherwise if printed serial number duplicate for a single ended or relector lamp on a

porcelain base, easy enough to add a letter to the serial number in

tracking it uniquely. I buy Osram dual ended lamps because they have unique serial numbers in addition to other reasons. Using an engraving tool or scribe to make a brand of dual lamp w/o unique serial number might damage the lamp's

base and void warranty. (Completely off topic - sorry)

Mark - I wasn't going to say "cost" in theorizing that if the lamp sockets were "valued" and bought that high, the lamps must also. Past talks I believe is that

socket costs are kept lower so as to make it easier to replace. That Osram training program for lamp science should be expanded to classes the local rep. can do and train down to the college

level. Though I'm sure you love giving the class. At least where I work, it was a great

introduction to lamps which with time can become as standard as the free PDF's Osram offers on lamp science for each type of lamp. Though the

xenon lamp manual and troubleshooting in general can use more work. Wish more people could take the time to read them. Great manuals and for free many on this website have learned from.

Wood - I have found in the last year or two VL-3K fixtures have stabilized a lot in burning

thru lamp sockets. Must have been a software upgrade or something because I agree now as opposed to a few years ago there is a lot less of a problem with them. Perhaps the main show I was

tracking never cleaned filters or something in at the time I pissed off VL in my findings completely after study - there was a huge problem a few years ago and not just with one show. It was for a long time problem in even frequently only taking one lamp to destroy a lamp

socket. Was a expensive problem I suppose got fixed in not hearing back any further or more problems. I certainly wouldn't

base a lamp

socket change off a fan change, though often both might be needed if the fan went bad.

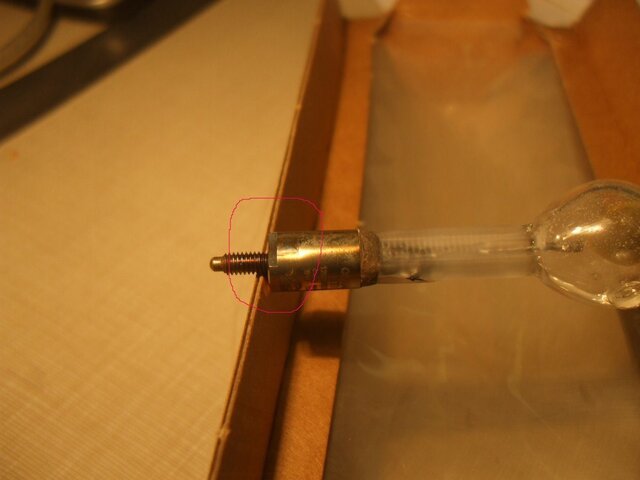

I trust the Osram tattoo to indicate a bad lamp

socket as per used on VL-3K fixtures. 8-10 I see possible these days in lamps used given the above. Not sure why they are getting more dependable than they were but I agree they are. They still run a little hot but are becoming very dependable if at about 750 hours between lamp changes. Not as dependable in a lamp lasting often double expected lamp hours of a

Mac 2K but that's because of the half burn mode when doused for lamps operating longer than expected lamp life but often doused while the audience seats.

Harmin/

Martin initially uses a Bender & Wurth lamp

socket in their fixtures. Initial problem - going back like fifteen years now if I remember correctly in the start of that myth was the keyway for the lamp in lamps installed up side down and bending the lamp

socket so it wouldn't seat the lamp properly. That was right about the start of when I started inspecting lamps and I won't have known much about lamps back than.

Throw the bad ones in the trash, if under hours,

return for warranty. About the extent of training I got for what these days is my primary job amongst other stuff. Come a long way and hope to go further.