bobgaggle

Well-Known Member

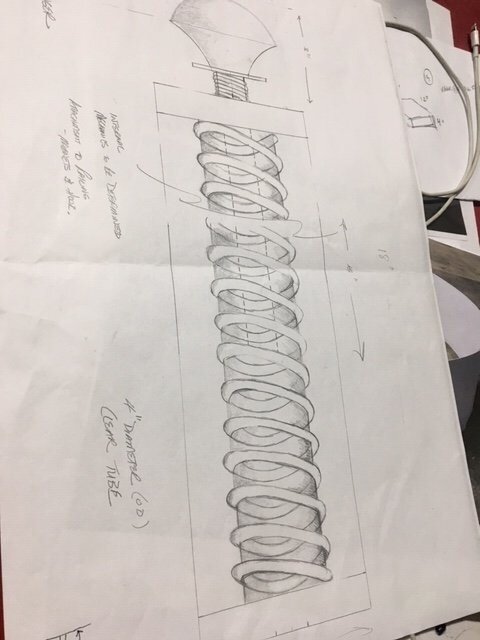

Hi all, I'm building a scaled up version of a pin ball plunger. I need a spring of some kind to pull the plunger back into the body. Somewhere in the realm of 9" stroke length. Everyone wants to go with a gas spring to avoid the thing slamming back, but finding one that's light enough is proving tough. Screen door closers are too heavy to comfortably pull, and mcmaster and grainger are scant on lightweight (5lbs or less) gas springs with a long enough stroke. Extension springs are also proving hard to find, load rates climb the longer the extension length and get heavy at the end of the stroke. Not sure if im overthinking all this, any ideas?