Just curious to note if just the terminals can be purchased by themselves? Perhaps I should also find out why just one side is getting all full of carbon and loosing contact, but this may be common? I have tried the search feature, but perhaps I do not know the correct terminology...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

HPL 575 Sockets

- Thread starterPdub

- Start date

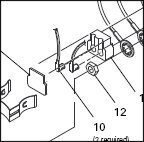

I guess that would depend on the definition of cleaned? I do not have access to any type of socket brush, but I have scraped and scoured with various different tools. The terminal seems to have been hot enough that it has lost tension and no longer grips the lamp pin. I have removed the cermaic block and let the lamp hang by the terminals and it works just fine, but when I reassemble everything as shown in image... no workie.

Just curious to note if just the terminals can be purchased by themselves? Perhaps I should also find out why just one side is getting all full of carbon and loosing contact, but this may be common? I have tried the search feature, but perhaps I do not know the correct terminology...

What you want to get is a TP-22H lamp socket. Your local dealer should be able to get them for you, or you can try calling BMI Supply, Production Advantage or Barbizon. They are easy to replace.

Have you tried cleaning the contacts?

DO NOT CLEAN YOUR LAMP SOCKETS OR LAMP PINS! If they are covered in carbon or corroded, replace them. Cleaning with any abrasive WILL change the way the lamp makes contact with the socket. This usually causes more arcing and will just cause the same problems!

Also, don't put a new lamp in a bad socket or put a bad lamp in a good socket.

Sorry for the metaphor, Pdub, but Alex's point cannot be made too often.

Lamp pin/contact arcing is like venereal disease: either can infect the other, and if not treated/contained immediately, one's entire inventory can become infected. Sockets (generally) cost just less than the price of one lamp; replace them at the first sign of trouble.

Ok, so cleanliness equals longevity in the lighting world

So can you buy new terminals to crimp on, see #10 ?

Not that I know of, however you can buy the leads with the terminals on them. Though the newer version of the TP-22H has everything as one piece. Much easier to install compared to the 4 piece version. Price should be the same (about $17.75 from BMI).

Not that I know of, however you can buy the leads with the terminals on them. Though the newer version of the TP-22H has everything as one piece. Much easier to install compared to the 4 piece version. Price should be the same (about $17.75 from BMI).

Does anyone even carry just the leads anymore? I have been using the "all in one" thing for some time now, they are fast and easy to put in. I want to say the going rate is around 15ish.

Long gone the seperate parts and good thing they are. Once had a person forget to install the mica shields behind her many replaced sockets a few years back over a number of fixtures. That was a shorting to frame bug hunt that took about a year to finally weed out.

Also, a pin and socket of that size... not worth cleaning much if at all. Bit of carbon at the most possible but after that and only very minor forget it - too small and not worth your time for what the end results will be.

Attached are some photos of some G-38 lamp sockets (38mm bet. pins at about 5/16" dia on the pins) as opposed to G-9.5 heat sink sockets at about 1/16" dia per pin. Yes, its possible to resurface a lamp socket, but it had at best be cost effective to do so and you had at best be able to get at what you are working on to do it properly. In the case of a S-4 fixture much less a PAR lamp or most other sockets undre a G-22 or P-28s in size.... nope nada in really having an effect on the socket.

This above and beyond the concept of cleaning / resurfacing takes away material from the socket be it coating which helps with heat or in general surface area that contacts the pins in providing a good electrical contact. If in either case what you will be doing will remove it, probably what you will do will only be a short term fix and that at best. Sure if a bit of oxidation you can clear away it and provide a coating to the fresh metal but after that and if such a coating is not provided in protecting the surface forget about it. And on a S-4 base, it's not enough metal to provide a coating or even service without removing too much properly.

Why since it's just a crimp terminal ETC didn't make available its sockets in the old style fittings to the market cheap is no doubt part of lore for the industry in how easy it would be to save the whip and replace the terminal, but on the other hand the modern socket does protect against as above the person forgetting the mica shield or not properly installing the base as it were. Price for the new socket assembly is also not that much more than a lamp and falls in line in price with most similar socket prices. Well worth not just that investment but a spare pre-done lamp cap at least that can be swapped out for in a pinch.

And as always, inspect the lamps removed from a fixture for what caused its failure and the pins for especially in the pins an indicator of when a fixtures socket is toast. Wouldn't believe how much money per year goes down the tubes especially for moving light lamps we waste on lamps simply because someone changing the lamp didn't bother to look at the lamp pins in seeing the socket it was attached to was toast. Often two or three lamps later such a thing welds itself to the socket in having to finally change the socket. Hmm, like $30.00 for a new socket, but it takes about over $300.00 worth of lamps to finally see the socket is causing the lamps to become toast before their time. And this only after ultimate failure of the socket.

Changing lamp sockets when they start to go is a cheap investment as opposed to what the cost in lamps going bad with a bad but not persay seen to be bad short of welding to the lamp costs can run up. Inspect them bad lamps for the cause of the failure and the pins before installing a new lamp in its place.

If in doubt, or not able to have skilled labor analize the bad lamps, have that pre-inspected or spare lamp cap go up with every lamp replacement and don't toss the lamp so later someone can inspect both without having to do so on the fly.

Also, a pin and socket of that size... not worth cleaning much if at all. Bit of carbon at the most possible but after that and only very minor forget it - too small and not worth your time for what the end results will be.

Attached are some photos of some G-38 lamp sockets (38mm bet. pins at about 5/16" dia on the pins) as opposed to G-9.5 heat sink sockets at about 1/16" dia per pin. Yes, its possible to resurface a lamp socket, but it had at best be cost effective to do so and you had at best be able to get at what you are working on to do it properly. In the case of a S-4 fixture much less a PAR lamp or most other sockets undre a G-22 or P-28s in size.... nope nada in really having an effect on the socket.

This above and beyond the concept of cleaning / resurfacing takes away material from the socket be it coating which helps with heat or in general surface area that contacts the pins in providing a good electrical contact. If in either case what you will be doing will remove it, probably what you will do will only be a short term fix and that at best. Sure if a bit of oxidation you can clear away it and provide a coating to the fresh metal but after that and if such a coating is not provided in protecting the surface forget about it. And on a S-4 base, it's not enough metal to provide a coating or even service without removing too much properly.

Why since it's just a crimp terminal ETC didn't make available its sockets in the old style fittings to the market cheap is no doubt part of lore for the industry in how easy it would be to save the whip and replace the terminal, but on the other hand the modern socket does protect against as above the person forgetting the mica shield or not properly installing the base as it were. Price for the new socket assembly is also not that much more than a lamp and falls in line in price with most similar socket prices. Well worth not just that investment but a spare pre-done lamp cap at least that can be swapped out for in a pinch.

And as always, inspect the lamps removed from a fixture for what caused its failure and the pins for especially in the pins an indicator of when a fixtures socket is toast. Wouldn't believe how much money per year goes down the tubes especially for moving light lamps we waste on lamps simply because someone changing the lamp didn't bother to look at the lamp pins in seeing the socket it was attached to was toast. Often two or three lamps later such a thing welds itself to the socket in having to finally change the socket. Hmm, like $30.00 for a new socket, but it takes about over $300.00 worth of lamps to finally see the socket is causing the lamps to become toast before their time. And this only after ultimate failure of the socket.

Changing lamp sockets when they start to go is a cheap investment as opposed to what the cost in lamps going bad with a bad but not persay seen to be bad short of welding to the lamp costs can run up. Inspect them bad lamps for the cause of the failure and the pins before installing a new lamp in its place.

If in doubt, or not able to have skilled labor analize the bad lamps, have that pre-inspected or spare lamp cap go up with every lamp replacement and don't toss the lamp so later someone can inspect both without having to do so on the fly.

Attachments

Last edited:

Sayen

Active Member

This would be why I finally stopped letting students change lamps. I'm all for giving them a nice broad education, but I got tired of replacing sockets on a regular basis, although I'm sure my local supplier didn't mind. My favorite was the set of 750W bases where the lamps were installed on top of the retaining clip. I'm in the habit now of checking every base when I change a lamp.

jfbulbtronics

Member

I work for Bulbtronics and we supply these sockets. As far as i know, you cannot buy only the terminals, but i could be wrong about that. If you are looking to buy the whole socket, you can either use the Osram TP22H which is currently the OEM Socket that ETC uses. You can also try using the Bender & Wirth 969/37099 which was the OEM socket for the Source Four until recently. They both have similar price points.

See this post: http://www.controlbooth.com/forums/lighting/8005-etc-source-4-porcelain.html#post94019, as well as the information contained in the thread.

thenelsontwins

Member

Agreed.

Just replace the whole set. I think ETC now only sells the 'kit' to vendors, (at least my old vendor), leads with socket terminals attached with porcelain et cetera.

Cleaning only makes it worse. Jamming something down in there to remove the carbon will only increase the air gap between the socked and the lamp pins and then you are doing it all over again.

Just replace the whole set. I think ETC now only sells the 'kit' to vendors, (at least my old vendor), leads with socket terminals attached with porcelain et cetera.

Cleaning only makes it worse. Jamming something down in there to remove the carbon will only increase the air gap between the socked and the lamp pins and then you are doing it all over again.

Lightingguy32

Active Member

As several of the other posters have mentioned the TP22H from Osram is probably your best bet. Unfourtanitly I have had a bad experience with the Bender&Wirth variant (several OEM sockets that broke within a month of purchase (manufacture defect)), but either of these sockets purchased to replace the older TP22- gold contact type socket is better than the original TP22.

Similar threads

- Replies

- 5

- Views

- 2K

- Replies

- 0

- Views

- 594

Conventional Fixtures

Lycian 1209 Midget HP Dual ended lamp version?

- Replies

- 9

- Views

- 3K

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)