Bubby4j

Active Member

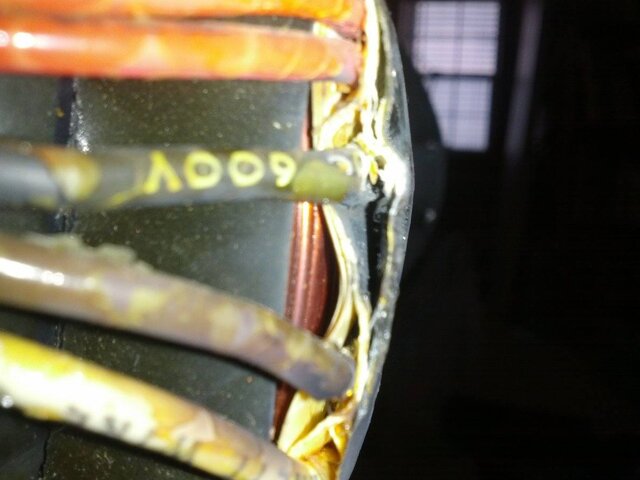

I had a very exciting evening, when I was adjusting one of my Intellabeams suddenly there was lots of arcing between the body of the Intellabeam and a truss (luckily I was standing on rubber!). I know that part of the problem is that the power the Intellabeam was connected to was not grounded (not making that mistake again!).

I looked inside and didn't see any wires contacting the body. (Was just a quick inspection, will be looking at it thoroughly later). I don't think that the breaker tripped. (Unless someone turned it back on before I checked.)

As I see it, there's 3 possiblities:

I check the truss against a ground with a multimeter shortly after the event occurred, and the potential was only 1 volt. Unless the breaker for the wire that could have potentially been touching the truss tripped, this couldn't be it.

Any ideas?

Pictures:

I looked inside and didn't see any wires contacting the body. (Was just a quick inspection, will be looking at it thoroughly later). I don't think that the breaker tripped. (Unless someone turned it back on before I checked.)

As I see it, there's 3 possiblities:

- The truss was energized

- The Intellabeam body was energized by a wire directly contacting it

- Some other weird electrical thing happened inside the Intellabeam leaking to the body

I check the truss against a ground with a multimeter shortly after the event occurred, and the potential was only 1 volt. Unless the breaker for the wire that could have potentially been touching the truss tripped, this couldn't be it.

Any ideas?

Pictures: