SHCP

Well-Known Member

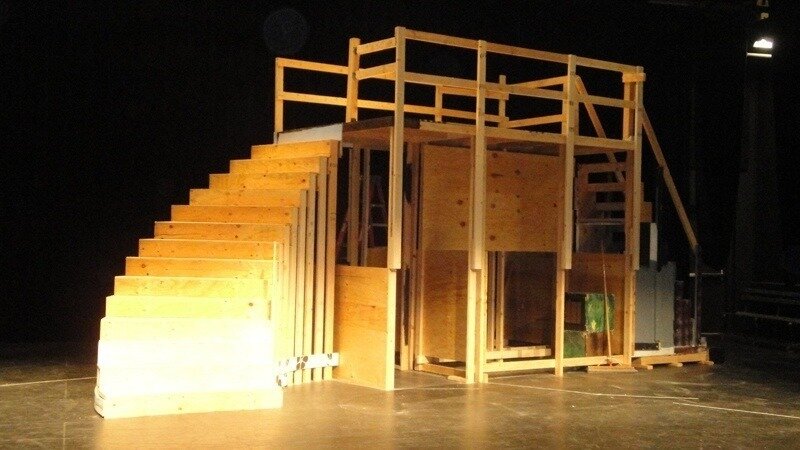

I thought I would post pics of the curved staircase I am working for The Miser.

It's a modular design, with treads that are 1' at the outside and 6" on the inside. The riser has a 14" overhand that bolts to the rear of the lower step's 7" rear support, making a 7 1/4 inch rise for each step. Its working out very well. The platform is at 9'.

I added plywood shear support to the back of every 4th stair support. It is very stable.

Now I just have to figger out the railing....

Tim

https://docs.google.com/a/shcp.edu/document/d/1l5KPnWk34JpIpcc6VEU-yIQtnrSUeL9e4-1tz97uenU/edit

It's a modular design, with treads that are 1' at the outside and 6" on the inside. The riser has a 14" overhand that bolts to the rear of the lower step's 7" rear support, making a 7 1/4 inch rise for each step. Its working out very well. The platform is at 9'.

I added plywood shear support to the back of every 4th stair support. It is very stable.

Now I just have to figger out the railing....

Tim

https://docs.google.com/a/shcp.edu/document/d/1l5KPnWk34JpIpcc6VEU-yIQtnrSUeL9e4-1tz97uenU/edit