Ship’s new LED work table work light.

Moving post given interest to a new topic.

New stuff from tonight:

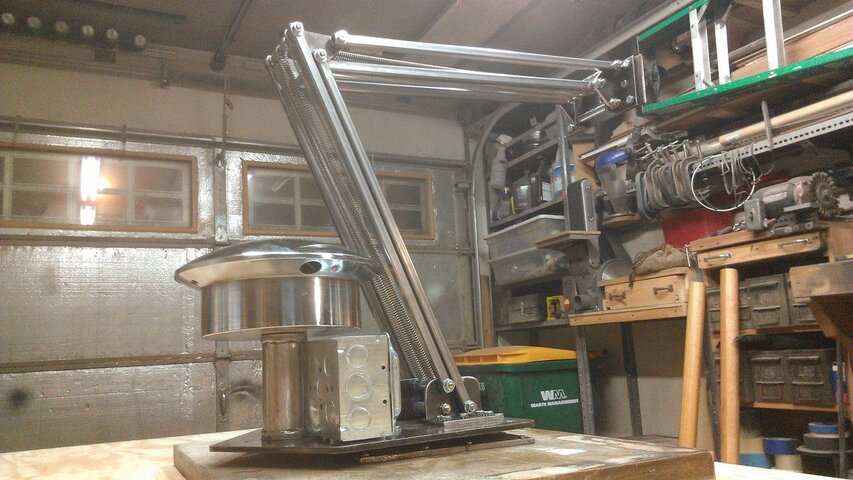

Fixture specified weight is 10#, add some given the spacers and new LED lamps. (Nice to have an early 70's Mole catalog at home and a later and more compete 70's Mole catalogue at work.) Just added a third ½" x 15" 10# tension spring to the upper portion of the support arm. A lot of taking apart and at times parts spring off somewhere with each change. Means 30# of tension on lower and upper arms, and believe me... you get a finger caught in one, you know it!!! Not a engineering person per say past books read... but for me, it’s still a little light in even if up to 15# of weight it will support short of very tensioned screws. The arms with limited travel need either more tension and less springs in larger dia. perhaps or just have to keep tension on them over use. Yet to mount the fixture - one more plate to add in mounting it. Thinking that even 30# of weight rating on the arms, I need more tension TBA.

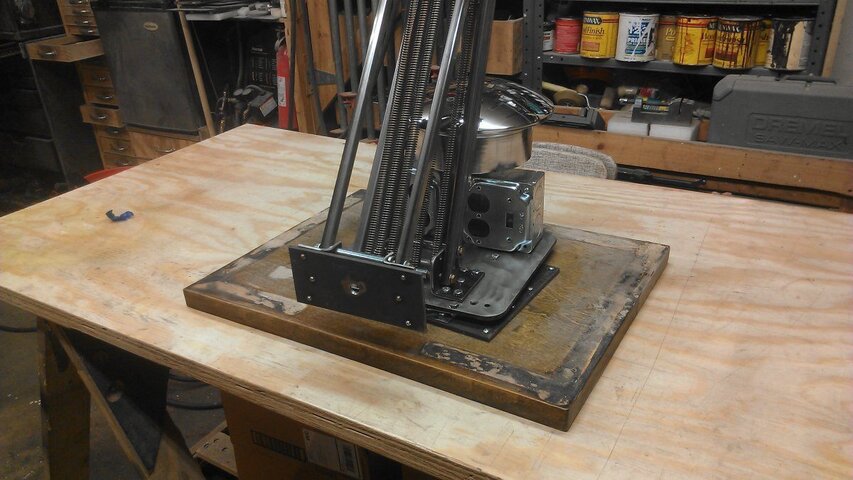

Overall it’s a monster drafting arm 3.1/2" in width and 1.3/4" in height. 16ga steel 1/2x1/2" 18.1/2" box tubing making it up with spacers seperating and now three each 10# spring per four arm section.

The power supply is going to be one of those for wire rope mounted knob and tube type low voltage fixtures. The kinds that have monkeys upside down on a wheel attaching a lamp or something like that.

"Kable Lite System", ETL listed/UL listed Misc. Fixtures, Tech Lighting inc. - Chicago. Imput, 120VAC - 4 AMP, Output 12VAC 40 AMP.

Nice huge 12v transformer I used to use for my garage box spot MR-16 50w/12v work lights before I went T8 16x flourescent. Lots of cantilever weight added to the turn table platform as with the standoff for it in mounting the mushroom of transformer. Thinking I’ll do a duplex L5-15 outlet and have a second outlet for test lamps at 12VAC available at my work table. Limit the breaker to 20 amps on the output and it should be enough for test stuff and power up the work lights should I ever need all.

Past post:

I'm working on a LED work light for my work table at work amongst other projects.

Articulating drafting table light arm on a swivel springed loaded up for like a 15# load. The arm is proving difficult to engineer what is seemingly easy except that I am mounting a heavy Mole 12"x16" lighting fixture on the arm from it's yoke. Large scale articulating arm assembly on a swivel base. Lived with drafting table lamp type arms all my life and never assumed that this would be the hardest part of the process. Base for it will be like a crane in having a cantiliever 1Kw transformer as ballast in weight and power at the bottom.

It is to mount an early/mid 70's Mole Richardson [HASHTAG]#5511[/HASHTAG] 5-lite Mole FAY PAR 36 MoleQuartz wash light. (Found it in a back store room, one already in the museum restored, four others restored and sent to a club with 4x [HASHTAG]#4596[/HASHTAG] ACL in series and a DWE in the center - they love them.)

In lamp, 5x switched Halco/ProLED PAR 36/9WW40/LED [HASHTAG]#80651[/HASHTAG] PAR 36 wash lights. They are 9 Watts/12Volts and 40 Degree beam spread, I will have lots of light on demand to supplement my Inkie current work table light. Challenge also with the Halco PAR 36 LED lamp is it's not designed properly, the rear mounting/seat dia. for the lamp is 4" in dia which is 1/4" too large for any normal PAR 36 fixture . Very odd in me having to hand cut and sand 1/8" spacers 4" ID. 4.3/4" O.D. so as to properly seat the lamp hopefully. Otherwise I have some extra 1/32" spacers TBA. Very odd lamp in it won't seat properly in any fixture it is supposed to mount into.

Main goals of the project to finally try this LED wash light (never powered one up yet), find a home/use for the antique light, get more light at my work table and the drill press next to it, and R&D what a early LED PAR 36 Audience blinder might be like given what is on the market by way of using stock fixtures with replacement LED lamps in them. Who knows, might be a good thing for the future in R&D.

Working on a large crane arm assembly with a large 1Kw transformer ballast for it, fixture is fully restored. (New topic for discussion once done.)

Moving post given interest to a new topic.

New stuff from tonight:

Fixture specified weight is 10#, add some given the spacers and new LED lamps. (Nice to have an early 70's Mole catalog at home and a later and more compete 70's Mole catalogue at work.) Just added a third ½" x 15" 10# tension spring to the upper portion of the support arm. A lot of taking apart and at times parts spring off somewhere with each change. Means 30# of tension on lower and upper arms, and believe me... you get a finger caught in one, you know it!!! Not a engineering person per say past books read... but for me, it’s still a little light in even if up to 15# of weight it will support short of very tensioned screws. The arms with limited travel need either more tension and less springs in larger dia. perhaps or just have to keep tension on them over use. Yet to mount the fixture - one more plate to add in mounting it. Thinking that even 30# of weight rating on the arms, I need more tension TBA.

Overall it’s a monster drafting arm 3.1/2" in width and 1.3/4" in height. 16ga steel 1/2x1/2" 18.1/2" box tubing making it up with spacers seperating and now three each 10# spring per four arm section.

The power supply is going to be one of those for wire rope mounted knob and tube type low voltage fixtures. The kinds that have monkeys upside down on a wheel attaching a lamp or something like that.

"Kable Lite System", ETL listed/UL listed Misc. Fixtures, Tech Lighting inc. - Chicago. Imput, 120VAC - 4 AMP, Output 12VAC 40 AMP.

Nice huge 12v transformer I used to use for my garage box spot MR-16 50w/12v work lights before I went T8 16x flourescent. Lots of cantilever weight added to the turn table platform as with the standoff for it in mounting the mushroom of transformer. Thinking I’ll do a duplex L5-15 outlet and have a second outlet for test lamps at 12VAC available at my work table. Limit the breaker to 20 amps on the output and it should be enough for test stuff and power up the work lights should I ever need all.

Past post:

I'm working on a LED work light for my work table at work amongst other projects.

Articulating drafting table light arm on a swivel springed loaded up for like a 15# load. The arm is proving difficult to engineer what is seemingly easy except that I am mounting a heavy Mole 12"x16" lighting fixture on the arm from it's yoke. Large scale articulating arm assembly on a swivel base. Lived with drafting table lamp type arms all my life and never assumed that this would be the hardest part of the process. Base for it will be like a crane in having a cantiliever 1Kw transformer as ballast in weight and power at the bottom.

It is to mount an early/mid 70's Mole Richardson [HASHTAG]#5511[/HASHTAG] 5-lite Mole FAY PAR 36 MoleQuartz wash light. (Found it in a back store room, one already in the museum restored, four others restored and sent to a club with 4x [HASHTAG]#4596[/HASHTAG] ACL in series and a DWE in the center - they love them.)

In lamp, 5x switched Halco/ProLED PAR 36/9WW40/LED [HASHTAG]#80651[/HASHTAG] PAR 36 wash lights. They are 9 Watts/12Volts and 40 Degree beam spread, I will have lots of light on demand to supplement my Inkie current work table light. Challenge also with the Halco PAR 36 LED lamp is it's not designed properly, the rear mounting/seat dia. for the lamp is 4" in dia which is 1/4" too large for any normal PAR 36 fixture . Very odd in me having to hand cut and sand 1/8" spacers 4" ID. 4.3/4" O.D. so as to properly seat the lamp hopefully. Otherwise I have some extra 1/32" spacers TBA. Very odd lamp in it won't seat properly in any fixture it is supposed to mount into.

Main goals of the project to finally try this LED wash light (never powered one up yet), find a home/use for the antique light, get more light at my work table and the drill press next to it, and R&D what a early LED PAR 36 Audience blinder might be like given what is on the market by way of using stock fixtures with replacement LED lamps in them. Who knows, might be a good thing for the future in R&D.

Working on a large crane arm assembly with a large 1Kw transformer ballast for it, fixture is fully restored. (New topic for discussion once done.)

Last edited: